What Will You Prospect From Vacuum Emulsifying Mixer?

In the fields of raw material pharmaceuticals, biopharmaceuticals, etc., vacuum emulsifying machine is a commonly used equipment.

Vacuum emulsification means that when the material is in a vacuum state, a high shear emulsifier is used to quickly and uniformly distribute one phase or multiple phases into another continuous phase, and with the strong kinetic energy brought by the machine, the material is narrowed in the stator and rotor.

It is subjected to the comprehensive effects of hydraulic shearing, centrifugal extrusion, impact and tearing in the gap, and it is dispersed and emulsified evenly in an instant.

With the continuous development of technology, the demands and requirements of the pharmaceutical industry are constantly changing. Manufacturers of vacuum emulsifiers need to continuously expand their fields of use and keep technology updated, and integrate technology and capabilities in order to promote the continuous development of the vacuum emulsifying industry.

On the one hand, the structure of the domestic vacuum emulsifying mixer needs to be optimized urgently, and the core technology is lacking.

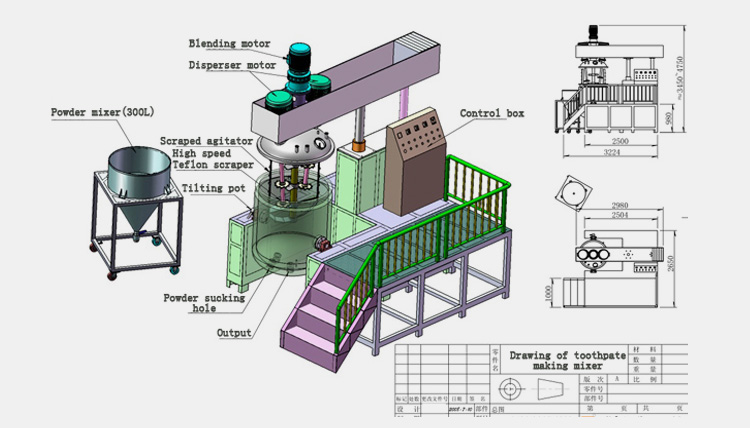

The industry pointed out that the core structure of the vacuum emulsifier is the stator and rotor system, and its structure has a claw structure suitable for materials with a light specific gravity and easy to suspend, and a blade structure suitable for materials with a heavy specific gravity and easy to precipitate. "

So the most important thing about the mixer is how to select the model. Different mixer structures will affect the mixing results and efficiency."

It is reported that there are many domestic emulsifying manufacturers attach the importance to optimizing the core structure of the emulsifying machine. Because our country lack the core technology, these manufacturers can support the various types of industry blenders, which comes from the importing countries like Germany to satisfy the different working conditions.

On the other hand, looking at the vacuum emulsifier market, although the varieties of vacuum emulsifiers in China are relatively complete, the specifications are not perfect;

The development of host products is relatively good, but the auxiliary machinery is still relatively backward; and the high-end products and automation products are insufficient, and the proportion of emulsifiers is low.

From the perspective of the reasons, this is mainly because most of the company’s in China's vacuum emulsifier industry are still state-owned company’s, which are small in scale,weak in technical force, and restricted by the state-owned system, the mechanism is inflexible.

The overall development speed of new products are relatively slow and the precision, reliability, and stability of machine products need to be further improved.’

With the further intensification of the market competition of vacuum emulsifying mixer at home and abroad, the vacuum emulsifying machine manufacturers can not be satisfied with the existing state of affairs and reluctant to move forward.

They also need to seize the good polices , follow the giant company’ s step and actively invest in innovation to improve the automation and quality of the products.

At the same time, it is necessary to pay more attention to the development of auxiliary machinery to achieve "self-sufficiency", rather than relying on imports and being limited by people.

In addition, customers are becoming more and more careful in the selection of products. Except the beautiful and cost-effective performance, they will also pay attention to the homogenizing heads and stirring systems used in the products.

The vacuum emulsifying mixer manufacturers should respect customer needs and produce high-quality products. Guaranteed to be in good condition from the parts to the whole.

In the actual production and applications, many manufacturers will combine different types of stirring blades as much as possible according to customer needs to form various targeted stirring systems to improve the production efficiency of the emulsifying machine

It is reported that the vacuum emulsifying machine has many seals, so the dynamic and static rings of the mechanical seal should be replaced regularly. The cycle depends on the frequent use of the equipment.

The double-end mechanical seal should always check the cooling system to avoid cooling failure and burn the mechanical seal.

For the skeleton seal, the appropriate material should be selected according to the characteristics of the material, and it should be replaced regularly according to the maintenance manual when you use it.

Additionally, the motor and reducer should regularly change the lubricating grease according to the manual, and the machines that are used more frequently should check the viscosity and acidity of the lubricating oil in advance, and replace the lubricating oil in advance.

Except for the regular maintenance of equipment, it is necessary for you to master the malfunction and troubleshooting methods of the vacuum emulsifying mixer.

When the vacuum emulsifying machine have some troubles during operation, it should be stopped immediately for inspection, and then run after the failure is eliminated. Generally speaking.

The common faults of vacuum emulsifier can be eliminated through the following inspection work.

First, check whether the power supply is normally supplied, whether there is leakage in the power cord, whether the motor fan blades are running normally, and whether the motor is faulty.

Second, check whether the vacuum pipeline is airtight and whether the sealing ring is leaking.

Third, check whether the vacuum valve is open, whether the vacuum pump is filled with oil or whether the vacuum pump water tank is filled with water, and whether the rotation direction of the vacuum pump is correct.

Fourth, check whether the stirring paddle is eccentric and whether the scraper is seriously worn.

Fifth, check whether the scraper is stuck with foreign objects, which makes it unable to rotate flexibly.

Sixth, check whether the homogenizing head is normal, whether there is any foreign matter stuck in the homogenizing head, whether the relay of the electric control cabinet jumps out, and whether the limit switch is loosened.

In general, the market prospect of vacuum emulsifying mixers are considerable. In the process of continuously obtaining business opportunities, competitive company’s also need to constantly accept the challenges given by the market.

In the fierce competition in domestic and foreign markets, company’s must continuously improve the level of science and technology, and produce more high-quality and cost-effective machines in order to achieve their own continuous improvement.

The purpose of development is to help the entire vacuum emulsifier industry to move towards a better future.

Don't forget to share this post!

Vacuum Emulsifying Mixer Related Posts

Vacuum Emulsifying Mixer Related Products

Vacuum Emulsifying Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine