How To Improve The Filling Quality Of Automatic Capsule Filling Machine?

Capsules are prepared by filling the powder or formulation containing active ingredients and the mixtures of active ingredients with combinations of different excipients by the usage of different capsule filling machines.

To form a capsule, the powder or formulation containing active ingredients and the mixtures of active ingredients with combinations of different excipient materials are filled with the help of filling rings into the body of the capsule from the powder hopper and then close the body of the capsule with the cap by the help of second filling ring.

There are more than 1600 installations worldwide for different types of capsule fillers. Capsule filling machines, or encapsulation machines, are mechanical devices commonly used for industrial and pharmaceutical purposes.

Capsule filling machines are also known as capsule fillers, encapsulators, or encapsulating machines. These can be classified into three types: automatic capsule filler, semi-automatic capsule filler, and a manual capsule filler. The general advantage of encapsulators is that it enables users to fill different types of materials in different types of capsules. Commercial grade capsule fillers enable mass-production of pills and supplements.

It is reported that a pharmaceutical company said during the production of capsules, due to the fine powder, they have to manually picking the defected capsules due to the fine powder.

However,the technical staffs on this pharmaceutical company carry ou some research and through the continuous optimisation of the automatic capsule filling machine and continuous debugging,the appearance of defective capsules have been greatly reduced and the cost of labor also been reduced.

So now ,the industry expert on this industry,pointed out that the filling quality of the capsule filling machine is crucial, and with the industry's tightening regulation, this has become a great concern for pharmaceutical companies, so the capsule filling machine equipment needs to continuously improve the equipment and optimise the structure of the equipment to help pharmaceutical companies to produce better.

"In addition to the quality of the equipment itself, the equipment environment, the transport process, and the various stations will have an impact on the quality of filling." Some filling machine manufacturers and technicians said that users need to pay special attention to several work stations of the equipment when operating the equipment, including the following parts.

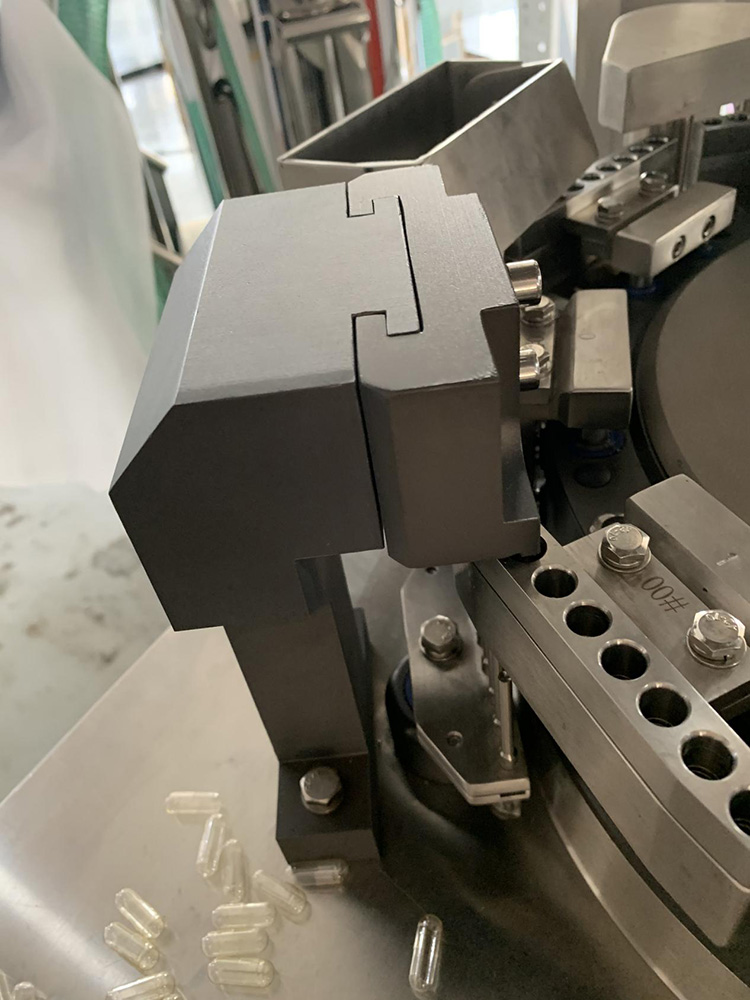

Firstly, the capsule turning and separation station. This station is the capsule feeding and separation mechanism, the purpose of which is to feed the capsule into the module and separate the capsule body and cap for the next step of drug filling.

Common problems in this station include poor separation and flying caps, etc. Technical staff remind that the pressure adjustment for vacuum separation should be appropriate, not too large or too small, too large will be the phenomenon of flying caps, too small will make the poor separation phenomenon occur.

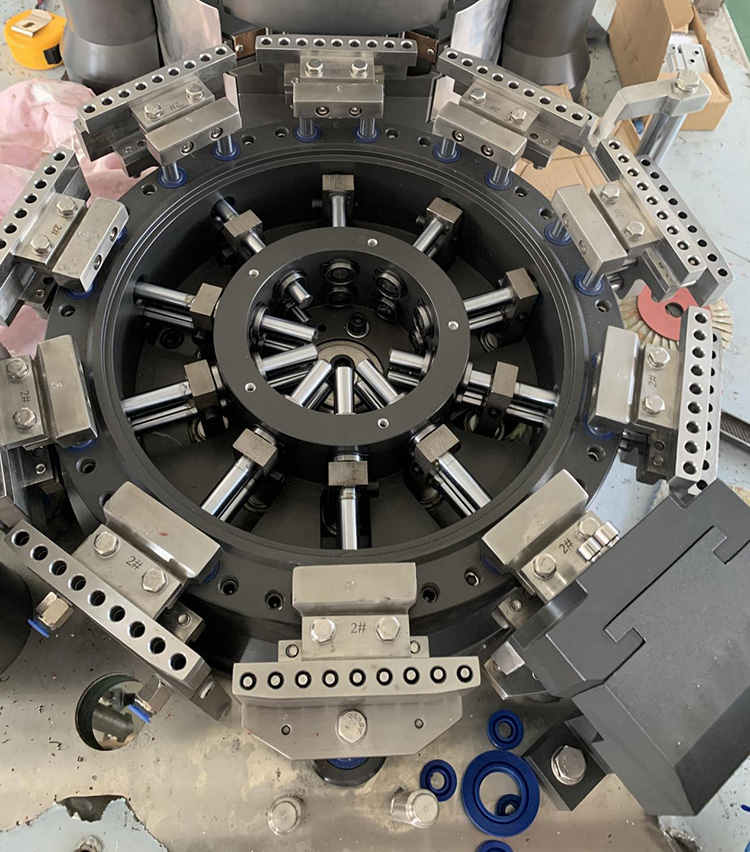

Second, the filling station. This station mainly controls the capsule contents of the filling weight, the main common problem is the filling of the contents of the weight is not stable.

The reasons for this are threefold: firstly, the metering tray is not well aligned with the lower module, making some of the finished capsules consistently lighter in weight. .

Technical staff pointed out that the problem is not easy to find here, the user in the production of preassembly, commissioning equipment must be well aligned here; second is the metering disc above the isolation block and metering disc gap is too large, so that when filling the drug through the gap into the metering hole resulting in the weight of the capsule is large. It is understood that the general isolation block and the measurement plate gap adjustment for 0.05 ~ 0.1mm for good, if too small will produce wear and tear on the measurement plate, damage to equipment.

In addition, the height of the powder on the metering disc has a certain impact on the filling weight, the powder height is too low, it will make the powder can not flow into the metering hole in time to cause the capsule light, the height is too high will make too much drug flow into the metering disc, the weight of the capsule is heavy.

Thirdly, the waste capsule reject station. The function of this station is to remove the badly separated capsules from the above stations. The key here, according to the technicians, is to adjust the size of the negative vacuum pressure to ensure that all unseparated capsules are removed, but that the capsules in the upper module are not sucked away. If the vacuum is too small, the capsules cannot be completely rejected; if the vacuum is too large, the capsules will be sucked away, resulting in unnecessary waste and a lower yield.

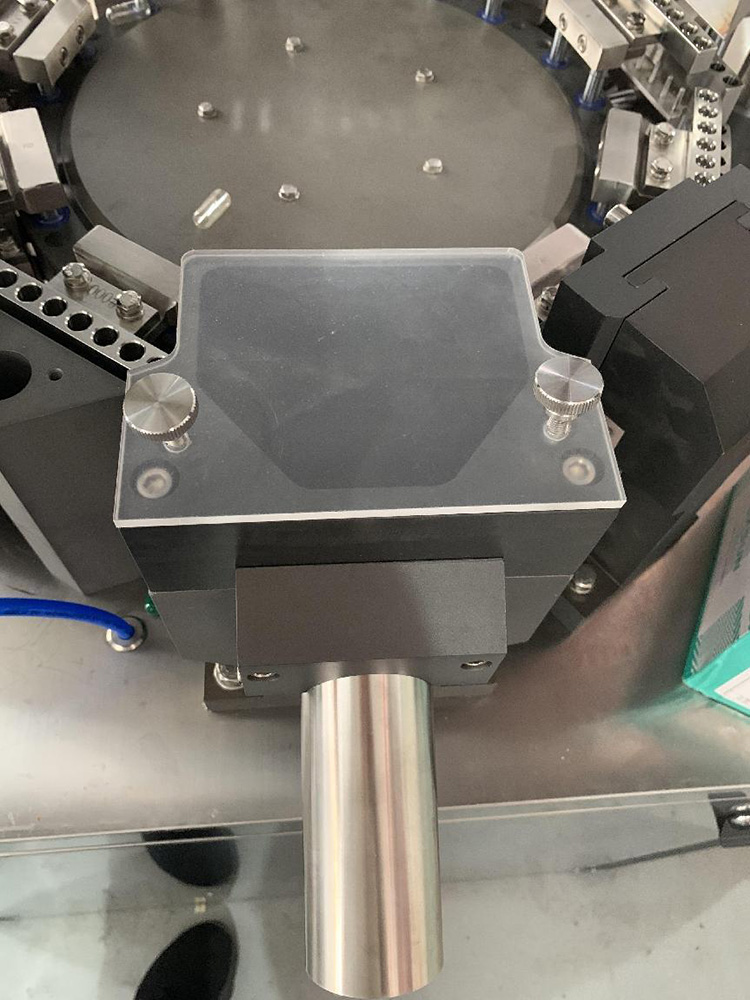

Fourthly, the capsule locking station. This station is an important step in the filling of capsules, the capsule body, capsule sleeve closure.

Common problems in this station include: capsule splitting, mainly due to poor alignment of the upper and lower modules, capsule body and capsule not being on the same centre line during locking, resulting in damage to the capsule body or capsule; poor locking condition, including capsule deflated head, capsule damage, and separation of capsule body and capsule from the finished capsule.

Deflated heads and damaged capsules are mainly caused by short locking lengths; capsule and capsule separation is caused by long locking lengths resulting in capsules not being locked tight and capsules separating during capsule transport.

The technicians suggest that the user should measure the locking length of the capsule when commissioning the equipment before production to ensure that it is within the qualified range, thus ensuring stable production of the capsule filling machine and guaranteeing the quality of the filling.

Conclusion

Fully-automatic capsule filling machine is a new type of enclosed equipment which is improved and innovatively designed based on the current domestic open-type equipment. Aesthetically in appearance, the machine is easy to operate and clean. Certified by CE, this capsule filling machine has been highly praised by the users.

Designed with a dosing disk, the capsule filler automates all processes including separation, filling, defective capsule rejection, capsule locking, and finished capsule ejection. Featuring a fully enclosed index table, the capsule machine is ideal pharmaceutical equipment for manufacturing hard capsules in the pharmaceutical and food industry. It's capable of filling capsules with powder, granules or pellets.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine