How To Choose The Right Bin Mixer?

Bin Mixer mixes two or more materials evenly through the mechanical forces and gravity. In the pharmaceutical industry, bin mixers can evenly mix different ingredients of material to form a compound. In this way, it can increase the contact area of the material to accelerate chemical reaction; And it also can accelerate physical changes. For example, if you want to put the granular solute into solvent, you can use a bin mixer to accelerate dissolution and mixing.

Currently, with the rapid development of the pharmaceutical industry, bin mixer plays an increasingly important role. With the expansion of bin mixer’s market, you need to improve the professional concentration degree. Product survival of the fittest situation is obvious so the requirements become higher and higher.

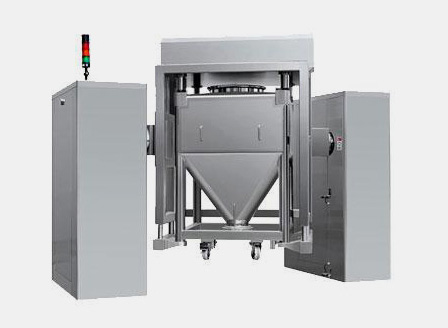

SWH Series 3D Motion Bin Mixer

For example, evenness is the key factor for customers to select a bin mixer. Because it requires all materials involved in mixing are evenly distributed.

The industry said that according to your requirements, the mixture degree can be divided into 3 states, ideal mixture, random mixture and totally incompatible mixture. The mixture degree of various materials in a bin mixer depends on the proportion of mixed materials, physical state, characteristic, the type of the bin mixer and the duration of the mixing operation.

A good bin mixer equips with a good uniformity, which can bring satisfactory benefits to pharmaceutical and other manufacturing enterprises, improving the mixture’s efficiency and ensuring the quality after mixing.

GHS High speed Bin Mixer

In addition, you need to pay attention to the following issues, the physical properties and chemical properties of various materials and their impact on bin mixers. Whether there are some special processing requirements in the mixing. And the installation space of a bin mixer. Because of different limitations, there are different bin mixers on the market, so it is hard to make a certain standard. In general, it requires users to select the proper bin mixture according to the production conditions.

For example, in addition to the difference in structural strength and power, the bin mixer’s discharging door, rotor, engine body and others tactic form, even the rotate speed and other performance parameters often have a big difference. So it is important for you to choose the corresponding box mixer according to the proportion of the material.

Model CH-VI Forced-Type Bin Mixer

It is reported that there are many users who will choose the original domestic vertical cone bin mixer, but the experts suggest that due to the many disadvantages of vertical cone mixers, such as

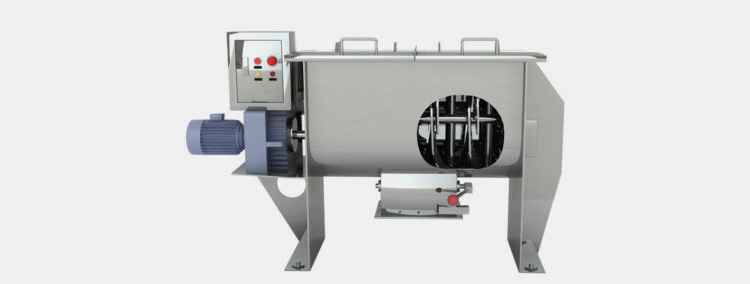

not suitable for powder and powder mixing, high maintenance cost. So if you want to mix powder and granular materials, you can choose WLDH- Horizontal Ribbon Bin Mixer . This machine has features with high efficiency of mixing, high quality of mixing, short unloading time and less residue.

On the other hand, the installation space is commonly needed to consider when you choose a bin mixer. You should know that Horizontal Ribbon Bin Mixer is generally suitable for occasions where the area is large and the height is limited, vertical mixers are the opposite, vertical mixers are suitable for limited space. Compared with other mixing equipment of the same specification, the gravity-free mixer and V-type mixer generally take up much more space, but they also have the advantages of being easy to move and easy to arrange.

WLDH- Horizontal Ribbon Bin Mixer

Additionally, as for the materials mixing, which needs to be heated and work with electro-chemical reactions, you should choose a proper making material and a good temperature control system. Besides, you should pay more attention to the effect of temperature changes on the equipment itself.

To select a high-quality bin mixer is very important, but before you use a bin mixer for producing, the following things need to be noted. Prior to application, you should carry out a no-run test, check the strength of all the connectors of the mixer, make sure of the completeness of lubricate oil volume and electrical equipment with the gear reducer. And then, close the main switch, connect the power supply, and carry out the no-run test.

Secondly, you should place this bin mixer in a stable place and install and pad the chassis so that this machine can run freely.

DLH Series Cone Bin Mixer

Thirdly, you need to refuel where you need to refuel and carry out a no-run test, observing whether the fasteners are loose, whether the electrical is normal, whether the machine runs smoothly, if there is something wrong, this machine needs to be repaired and adjusted again.

Fourthly, you should turn the feed port to the top and open the charging lid to charge. The quantity of charge can not exceed the specified volume. Tightly close the charging lid and put the machine into operation. If an exception is found during the process, the operator needs to stop to check

Fifthly, it is necessary for you to wash the funnel cleanly.

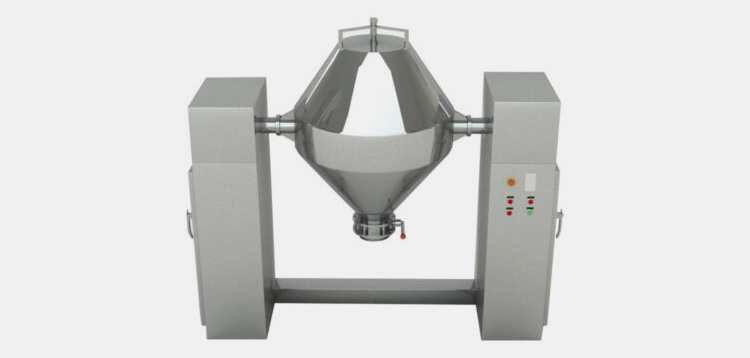

Model W Series Double Taper-shaped Bin Mixer

As for the market development status of small bin mixers, some experts express that a big bottleneck for the localization of modern hybrid technology is still the lack of system backwardness and innovation. So some experts suggest that if we want to accelerate the small bin mixer industry’s upgrading, we should positively promote the establishment and improvement of the technological innovation system with enterprises as the main body and strengthen the enterprise's ability to integrate and differentiate on the basis of digestion and absorption.

China is a big country in pharmaceutical machinery. Bin mixer has good development prospects. However, there is a certain disparity between domestic mixers and imported mixers. Though we have the advantages of cheap price and convenient maintenance, innovation is the key to progress. Bin mixer manufacturers should seize the current opportunities, doing a good job of re-innovation on the basis of digestion and absorption, and accelerate the pace of localization of large-scale key mixing equipment.

Don't forget to share this post!

Bin Mixer Related Posts

Bin Mixer Related Products

Bin Mixer Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours