How to Troubleshoot The 3 Biggest Problems Of Herb Crusher?

Under the background of the rapid development of the traditional Chinese medicine industry due to the favorable environment, the market prospect of the traditional herb crusher is broad, and the number of its manufacturers is gradually increasing.

However,the traditional herb crusher is suitable for small traditional Chinese medicine factories, traditional Chinese medicine stores, traditional Chinese medicine hospitals and other fields.

Moreover, with the development of modern automation and intelligent technology, as well as the increasing demand for traditional Chinese medicine products in the market, many traditional Chinese medicine crushing equipment are improved and upgraded in the direction of higher automation, higher work efficiency and simpler operation, so as to further meet the needs of users.

However, you may often encounter some problems in the process of using this herb crusher which affects the production of traditional Chinese medicine pulverization and the quality of products.

Specifically, there are the following problems, you will get how the problems are and how to troubleshoot them.

1.Agglomeration in crushing

How to solve the phenomenon of agglomeration is a problem that needs to be solved in the process of crushing traditional Chinese medicine. It is reported that dispersants (surfactants) play a very important role in the grinding process.

If the ground materials can be fully dispersed, agglomeration will not occur, and the so-called reverse grinding phenomenon will not occur. Therefore, the appropriate choice of dispersant is an effective way to solve the problem of reverse grinding.

Generally,for most materials, the longer the crushing time, the better the crushing effect. Otherwise, sometimes some materials reach a certain fineness, but it is not easy to crush; Sometimes the particle size of the material increases instead.

2.Production decline

Many users reported that the output of traditional herb crusher decreased after working for a period of time.

What is the reason? Actually, there are many reasons for the decline in the output of the herb crusher, such as too much moisture in the material, poor discharge of the crusher, inappropriate mesh size, fan configuration and other factors can affect the output of the crusher.

For example, too much moisture in the material will affect the efficiency of the herb crusher. "Materials with too much moisture are not easy to be crushed, and they are easy to block the mesh of the screen, which seriously affects the output of the herb crusher."

The industry expert suggested that the solution to this situation is to dry or sun dry the materials and then crush them.

Another reason that the discharge port is blocked, which will also affect the discharge speed of the herb crusher and lead to a decrease in output. And the solution to this situation is to clean the outlet, including the residual materials in the herb crusher chamber, to ensure the smoothness of the whole crushing process.

The pore size of the screen is also an important factor to control the crushing particle size.

The industry expert said that when the particle size required for crushing is different, the screen with different aperture should be replaced, otherwise the crushing efficiency will be reduced, or unqualified particles will be produced.

On the other hand, the opening rate of the screen affects the filtration speed of the screen. When the opening rate is too small, the efficiency of the herb crusher will naturally decline.

And the solution to the decline in output caused by the size of the screen's aperture is to replace the screen with the appropriate aperture and opening rate.

In addition, the problem of wind pressure configuration will also lead to a decline in production. It is understood that the rotor in the crusher will form a low-pressure area in the crushing chamber during operation, and the materials are not easy to fly out of the crushing chamber due to the influence of atmospheric pressure.

The purpose of configuring the pressure difference is to manually add a low-pressure area outside the crushing chamber. The pressure difference inside and outside the herb crusher chamber disappears, and the discharge speed of materials naturally increases. The solution is to configure a reasonable fan for the herb crusher.

3.Bearing Overheating

You may often encounter the problem of bearing overheating when the herb crusher is running,is this normal?

It is understood that there are many reasons for the bearing overheating.

For example, when the two bearing pedestals are uneven, or the motor rotor is not concentric with the crusher rotor, the shaft will bear the impact of additional load, resulting in bearing overheating. In this case, you should stop the machine immediately to eliminate the fault, so as to avoid early damage to the bearing.

"Too much, too little or aging lubricating oil in the bearing is also the main reason for overheating and damage of the bearing. You should fill with lubricating oil on time and quantitatively according to the requirements of the user manual.

Generally, lubrication accounts for 70%-80% of the bearing space. Too much or too little is not conducive to bearing lubrication and heat transfer." you are suggested.

In addition, when the fit between the bearing cover and the shaft is too tight, the fit between the bearing and the shaft is too tight or too loose, which will also cause the bearing to overheat. Once this kind of problem occurs, there will be friction sound and obvious swing during the operation of the equipment. At this time, you should shut down the machine to remove the bearing, repair the friction part, and then reassemble as required.

Conclusion

The main reason why herb crusher is so called is its great role - crushing traditional Chinese medicine, but this also hinders its multi-purpose characteristics. Is the traditional Chinese medicine crusher only used to break traditional Chinese medicine?

This situation has slowly changed. Traditional heb crushers are used to crush Cereals, feed raw materials in the laboratory of feed enterprises, samples in university laboratories, and chemical raw materials in chemical plants. Now thousands of herb crushers operate in all walks of life every day, playing an irreplaceable role.

How to crush traditional Chinese medicine and how to achieve the good medicinal effect after crushing has long been the scientific research goal of the manufacturers of traditional Chinese medicine pulverizers.

First of all, for the crushing of traditional Chinese medicine, you must understand the bioengineering of traditional Chinese medicine and pharmaceutical bioengineering, and to what extent can traditional Chinese medicine be crushed to obtain higher efficacy and higher solubility.

In fact, the development of the herb crusher is not only focus on the technological breakthrough, but also made systematic improvements in other aspects, which significantly improved the overall strength of the equipment.

Don't forget to share this post!

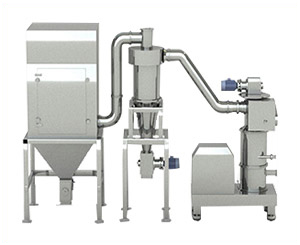

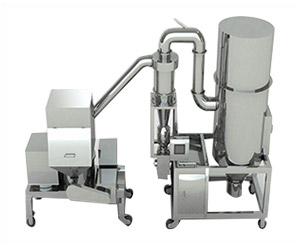

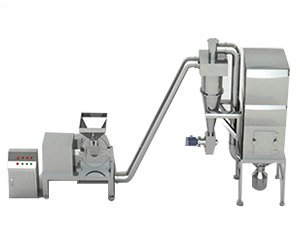

Crusher Machine Related Products

Crusher Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine