Bottle Labeling Machine: The Ultimate Buying Guide In 2025

‘Keep The Medicine Out Of Children’s Reach’, and Shake Before Use!

You commonly see such statements with other information on every medicinal bottle.

Thanks to the bottle labeling machine for efficiently performing this job!

When it comes to navigating its technology, Bottle Labeling Machine: The Ultimate Buying Guide is an especially designed effort to deliver maximum knowledge about it. Here, we explained the perfect solution that you need to know before purchasing the equipment.

1.What is a bottle labeling machine?

Bottle Labeling Machine

A bottle labeling is a useful equipment employed in several industries for dispensing, fixing, sticking paper covers, or printing label on the surface of bottles.

They print useful information like manufacturing date, expiry date, batch code, and bar code on the bottles.

Bottle labeling machines can easily handle various materials such as glass, plastic, and aluminum. These are employed for sticking various kinds of labels from stickers to paste labels, and to counterfeiting labels.

2.What are the types of bottle labeling machines?

Bottle labeling machines can be classified in three different ways based on automation, and design configuration.

BASED ON AUTOMATION

There are three types of bottle labeling machines based on automation

Semi-Automatic Bottle Labeling Machine

Semi-automatic bottle labeling machines are the pioneer of bottle labeling machines. They are simple and easy to operate without needing any special training.

Here, operators have to perform every function for instance, loading of film, placing the bottles, and removing the bottles from the machines.

These are a cost-effective solutions for small home-based firms as their purchasing does not require a lot of capital.

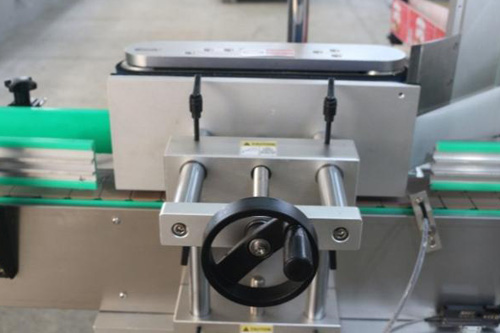

Automatic Bottle Labeling Machine

Bottle Labeling Machine

In automatic machines, there is minimal need for human supervision. Technicians just have to program instructions for running a machine on intelligent touch screen interface and rest of operation is performed by the machine itself.

These types of equipment load bottles by themselves. These carry out the labeling process and then automatically discharge bottles. These are extremely high production output and are particularly employed in mass scale businesses. Moreover, these can label multiple bottles differing in design concurrently.

BASED ON DESIGN

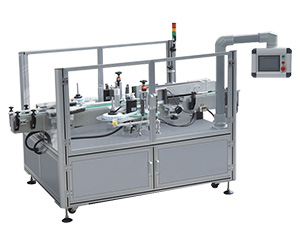

Vertical Wrap Bottle Labeling Machines

Bottle Labeling Machine

Here, the bottles are loaded in an upright position on conveyors. These are mostly suitable for bottles that have a square, rectangular or tapered design.

Both partial and full label films are applied by these machines.

They have a roller space configuration that assists in holding the bottles in place.

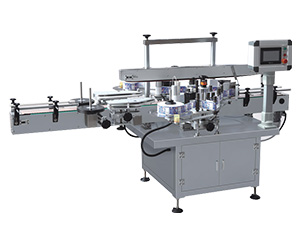

Horizontal Wrap Bottle Labeling Machines

Bottle Labeling Machine

The bottles are loaded on the machine at side way position and are in a horizontal position when passing through it. The machine is well suited for affixing labels on bottles that have an unstable base such as cylindrical bottom bottles.

It has idlers rollers fixed on attachment chins. These rollers aid in the labeling process.

Front/Back Bottle Labeling Machines

These are automatic machines and can handle bottles having an oval, irregular or rectangular shape. It can affix a label on one or both sides of the machine.

The machine can process bottles that have a stable base and remain in position while moving across the conveyor. The machine can be used for two, three, or four-side panel wrap labeling, but this may slow down the speed.

It might require a feed screw or walk beam alignment for holding oval or irregular-shaped bottles on conveyors.

3.What are the parts of the bottle labeling machine?

In bottle labeling machines, every part has a key function for the efficient and speedy application of labels. Every component works in coordination to achieve efficiency in the labeling process. Details of some parts of the machine are as follows:

| Holding Rollers

These rollers hold the bottles in place while the label is being applied to them. This does not allow bottles to move thus aiding in the accurate positioning of labels on bottles. |

|

| Feeding Screw

It is used to control the speed at which bottles are moving on conveyors. The feeding screw also prevents spillage of contents |

|

| Labeling Head

It is employed for sticking the label on the bottles via glue, pressure, or heat. |

|

| Motor

It is the electromechanical part that drives the whole labeling system. It converts electric energy to mechanical energy and provides the necessary power for ruining the machine. |

|

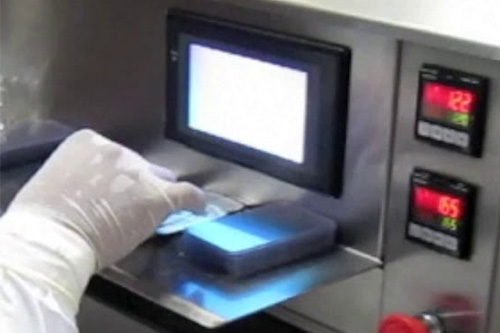

| HMI

It is regarded as brain of labeling machines as essential commands for efficient operation of machine are programmed on it. |

|

| Label Sensor

This recognizes the 1/8 inch space between labels and warns control system to stop the labeling process. This sensor is a type of electromechanical switch or photo-sensor. |

|

| Film Unwind Reel

It is about 12 to 13 inches in diameter and it is where the label film roll is placed. |

|

| Conveyors

These are mechanical handling part that automatically moves bottles from one station to another. |

|

4.What are the industrial applications of bottle labeling machines?

Bottle labeling machines are the need of every industry. These are utilized for sticking labels on cough syrups, foundations, glues, beverages, paints, etc. Some major uses of these machines are discussed below:

| Industry | Application | |

| Pharmaceutical Industry | Bottle labeling machines are an important part of the pharmaceutical manufacturing plant. It prints useful information about formula, expiry date, batch labels and intended use on bottles of cough syrups, antibiotics, gastric medications, effervescent tablets etc. |  |

| Food Industry | In the food industry, bottle labeling machines are used for sticking labels that display ingredient information. These are also used for illustrating facts about number of calories, fat, and alcohol content in food and beverages like condiments, soft drinks, coffee, jams, and creams. These labels also warn consumers about allergens in foodstuff. |

|

| Chemical Industry | Bottle labeling machines have found their use in the chemical industry as well since all the companies are required to present details about the hazardous nature of chemicals. These labels are useful while handling chemicals as their incorrect use can cause incidents. |

|

| Cosmetic Industry | The machines are used for printing labels on various kinds of cosmetic bottles like talcum powders, foundations, and hair and skin products. Guidelines about usage, formulating materials, and warnings are written on the bottle labels. |  |

| Agriculture Industry | Bottle labeling machine is popular in putting labels required for pesticides, insecticides, fertilizers, herbicides, etc. These labels give guidelines to farmers about application and precaution of using chemicals. |  |

5.What are the advantages of an ambidextrous bottle labeling machine?

Ambidextrous bottle labeling machines are needed for every big manufacturing firm. It brings you fast labeling and more profits. Some key advantages of this handy instrument are penned below.

| High Performance

|

Applying labels by hand is quite a tiresome and boring job. But with the help of bottle labeling machines, hundreds of labels per minute are applied to bottles. |

| Precision

|

Via label sensor, bottle labeling machines affix labels to bottles with precision and accuracy. These sensors can detect if the position of label is wrong thus gluing the label in the correct location. |

| Ease of Operation

|

The machines are comparatively easy to operate and manage. This equipment does not need a large number of operators for directing and running machine processes. |

| Versatility

|

Bottle labeling machines are tremendously versatile due to far-reaching applications in every manufacturing area. These can affix various types of labels like removable labels, anti-counterfeit labels, non-removable labels, etc |

| Customer Attraction | It plays an important role when considering consumer attraction. Because colorful graphics on the bottle’s surface increasing the chances for best production sales. |

| Cost-Effective | They are highly lucrative for the manufacturing sector due to high production capacity per minute than manual labors. Secondly, minimal supervision is required, thus saving your labor wages. |

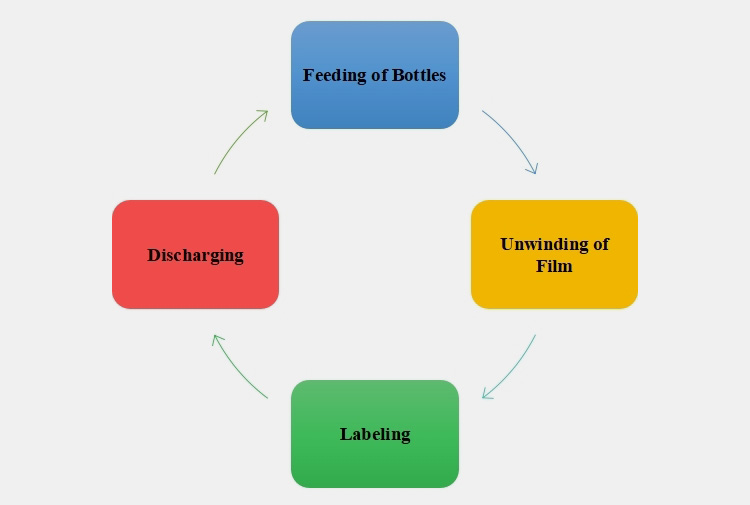

6.What is the basic working principle of a bottle labeling machine?

Understanding the details of the operational principle aids in resolving the problems in case of machine failure. In a labeling machine, every part is in complete synchronization to accomplish the labeling process.

Step by step guide is given below for your understanding.

Feeding of Bottles

At the first stage, the bottles are placed on the conveyors and the labeling system began to move simultaneously. These two systems are complete in harmonization with each other. Feeding screws are used for keeping a certain distance between two bottles.

Unwinding of Film

The film for labeling is placed on the unwind reel. The driver rollers aid in the unwinding of labeling film from the reel. These rollers drag the film which is then pulled out of the reel. Motors facilitate in dispensing of film.

Labeling

The labels are affixed on the bottles via labeling head. There is open-displacement control which provides necessary tension to labeling film.

The labeling head has a certain speed and is in complete coordination with speed of bottles moving on conveyors. With the label being attached, the labeling head stops.

The process is completely regulated and label sensor ensures the correct positioning of label by detecting the registration mark. When labeling head stop, the drive rollers correct positioning of labeling film.

Discharging

As soon as the labeling process is completed, the bottles leave the labeling machine by means of a discharge chute. The rejection unit detects accurate labeling of bottles by their aligned movement during the discharge process.

7.How a bottle labeling machine can improve the pharmaceutical manufacturing line?

A bottle labeling machine is an integral part of the pharmaceutical manufacturing line because these aid in displaying information about product use on medication bottles.

For improving the pharmaceutical production line, bottle labeling machine holds several properties:

| Flexibility and Expediency | The bottle labeling machines are easily modified to serve various medication packaging needs; these can be incorporated into existing lines or can be customized according to bottle and label style. |

| Installation and Portability

|

It can be installed effortlessly and conveyors belts on machine can be adjusted according to height of medication bottles. Furthermore, they are easily moved to other pharmaceutical productions. |

| Compliance

|

The bottle labeling machines are manufactured and design as per FDA and GMP regulations. It meets the criteria for safe and secure pharmaceutical production. |

| Quality

|

The quality of labeling is increased by superior action of the machine and margin of error in labeling is significantly reduced. It has consistency in placing pharmaceutical labels. |

| Better Consumer Service

|

A superior bottle labeling machine can immensely enhance your customer’s service report. They are employed for printing bar codes which assists in tracking shipment and ensures delivery of medications. |

| High Profits

|

Colorful graphics having instructions about use of medication, their formulation and ingredients appeal more to consumers than simple bottles. This means more profit and increased savings for the pharmaceutical industry. |

8.What are the technical problems and troubleshooting of a bottle labeling machine?

Problems and failures are part of every manufacturing line. A skilled technician knows about various errors in machines and does his best to resolve them.

Here few technical problems of bottle labeling machines and their solutions are detailed.

| Problem | Possible Cause | Remedies |

| Missing Label | Sensitivity of label sensor is not accurate. | Adjust the sensitivity of sensor. |

| Low speed of labeling head | Increase speed of labeling head | |

| High speed of a conveyor | Decrease speed of conveyor | |

| Wrinkles On Labels | A large amount of adhesive | Fix meter blades for decreasing the amount of glue. |

| Glue coverage is not proper | Adjust metering blades for increasing the amount of glue. | |

| Applying labels on wet bottle | Dry the bottle before applying labels. | |

| Defective wiper action | Clean and fix the wipers. | |

| No Labeling Film Feed | The labeling head is loose and cannot pull labeling film | Tighten the labeling head. |

| Labeling system is not working properly | Examine the labeling system for damage | |

| Labeling head is not connected to power source | Connect the power supply of labeling head. | |

| Labels cannot be attached to Bottle | Labeling head speed is extremely slow | Increase the speed of labeling head. |

| The gap between labels is too small | Enhance the velocity of clip belt. | |

| Labeling sticker is unclean | Clean the labeling film. | |

| Tearing of Labels | Peel Plate is damage | Replace old peel plate |

| Smearing of glue on Labels | Amount of glue is very high. | Fix the metering blades to have accurate amount of glue |

| High compression | Relax the wiper | |

| Slippage of labeling film | Examine labeling system for decreasing amount of adhesive | |

| Labels are recently printed | Use old labels | |

| Accumulation of adhesive on the prongs of the hopper | Wipe the prong for removing excess adhesive | |

| Lumpy label | Size of label is too large for bottle | Use properly sized label |

| Design of label is not correct | Use right styled label for curved bottles. |

9.What are the future trends of a bottle labeling machine?

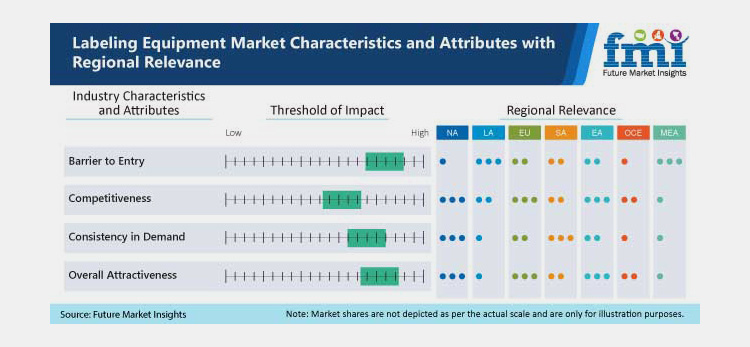

It has been estimated that the market worth of labeling machines was USD 2.5 billion in 2019 and will grow with a gain of CAGR of 3.6% to USD 2.9 billion in 2024.

This market expansion is owing to consumer demand for transparent products and also because of enforced regulation of authorities for labeling.

Everyday modern machines having latest technological controls, advance PLC systems, and high speed multiple labeling head are coming in market. They are equipped with highly accurate sensors and can have labeling speeds up to 18,000-40,000 bottles per hour.

CONCLUSION

Bottle labeling machines are simple, easy to use, and have high production capacity. It provides a consistent labeling result because of a highly sensitive sensor unit. Bottle labeling machines are worthy investments as these bring more profit by increasing the visual appeal of the bottles. For more help or technical support, feel free to contact us. We are available to help you 24/7/365.

Don't forget to share this post!

Automatic Labeling Machine Related Posts

Automatic Labeling Machine Related Products

Automatic Labeling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine