What Are The Pill Packaging Machine?

Do you know a large pharmaceutical industry can produce approximately 1.7 million pills per day? This could be of any size, shape, and color. Similarly, you can’t leave them exposed to the external environment as it may harm the quality, potency, and shelf life of the pill. So, you need to secure them immediately.

Every challenge has its own seed of growth and solution.

Modern sciences and technologies have introduced its solution in the form of pill packaging machines. What are the pill packaging machine? The article is created to discuss basic information about pill packaging machines and their role in boosting your business.

Table of Contents

I.What are the pill packaging machine?

Pill packaging machine is a robust solution for pill packing. It enables manufacturing companies, pharmacists, retailers, technicians, researchers, and nurses to dispense and prepare medication autonomously through accurate mode in a very lesser time.

A pill packaging machine is able to sort a variety of tablets and distribute them into assigned cavities or containers. Whether unit-dose or multi-dose packaging; it ensures a high level of safety and adherence to its consumers.

HISTORY- HOW OLD IS THIS TECHNIQUE?

Pill packaging is not a modern technique, its discovery and transition started many centuries ago. Let’s take the shortest glimpse.

| Before 17th Century |

Since the very earliest, medicines were dispensed in stone containers. Those containers were difficult to craft, porous in nature, and easily breakable. It was not an ideal solution for pill packaging. |

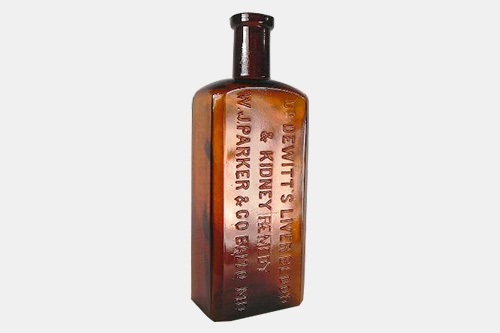

| Early 17th Century |

By the early 17th, glass bottles were introduced which were considerably more durable than stone containers. Over years, they came in various colors and became less expensive. Still, the glass was easy to break under certain conditions. |

| 18th Century |

Germany is a well-known hub in manufacturing packaging machinery. They introduced the world’s first packaging machine in 1861, and produced a fully automatic forming, filling, and sealing machine in 1911. Henry Smyser Philadelphia invented the first packaging filling & sealing machine. The machine was producing paper bag packaging. |

| 19th Century- Golden Era of Enhance Packaging | The first vertical form fill machine (sachet, pouch) was verified/patented in 1936 by Walter Zwoyer (worker of a candy manufacturing company).

Blister Packaging Machine Moving forward, blister packaging sprang into popularity in the early 60s, although this technology was verified in 1947 by Enock Ancker. As per our knowledge, you cannot exactly coin the name of the scientist who first invented this machine. |

TYPES

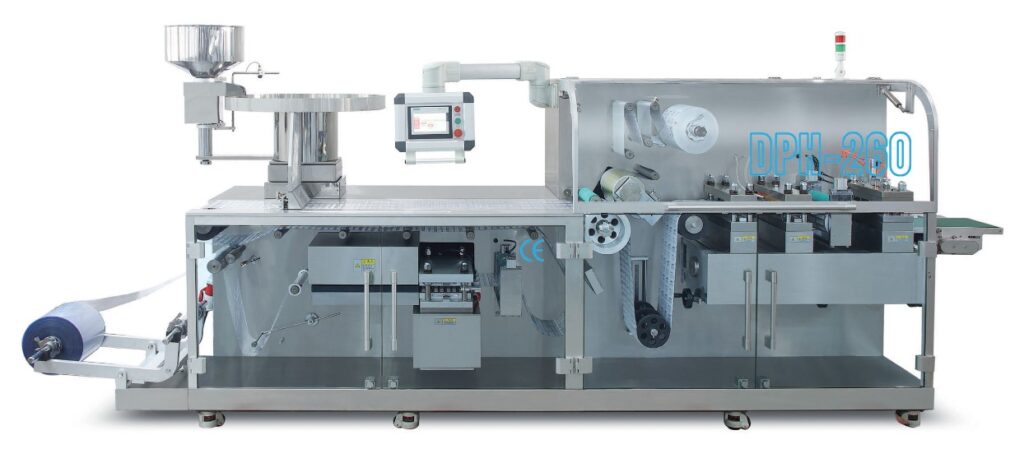

BLISTER PACKAGING MACHINE

Blister packaging machine

The blister packaging machine is well known and popular equipment in the medicinal industry. Besides pill packaging, it is utilized to pack injections, medical tools, vials, ampoules, etc., The mechanical movement of the blister packaging machine produces cavities where pills are introduced automatically and sealed with paperback, aluminum, or a film. The line is available semi-automatic to totally automatic machines suitable for small to medium, and large batches.

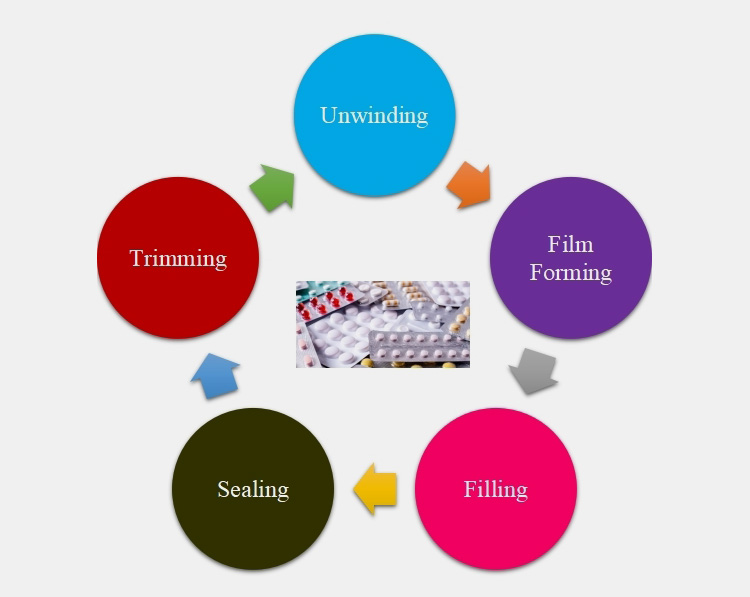

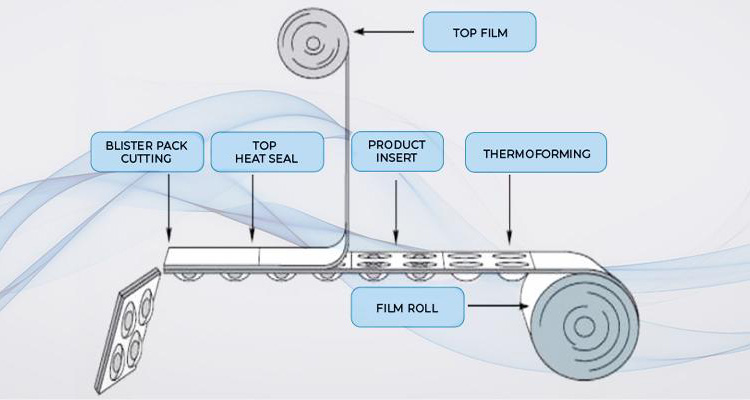

WORKING PRINCIPLE

The working principle of the blister packaging machine is discussed as followed:

Step 1: Unwinding

Aluminum foil or plastic film needs to be unwound with the help of a motor. The rotation of the bearing opens the film by guiding the roller.

Step 2: Film Forming

A film can be shaped as requested infeed to the forming mold. A heating temperature should be regulated according to the type of material e.g 110-130⁰C or higher. The heating method can be categorized into the radiant and conduction (contact) methods.

After heating the film, it is molded into shape with the following methods:

- Blister Forming: also termed as negative pressure forming. A softened film is pulled by vacuum to form a pocket.

- Blow Molding: is a positive pressure forming. Compressed air helps to blow PVC into the mold.

- Punch Assisted Blow Molding:a softened film is fixed with a punch and compressed air allows fixation with the mold.

- Cold Stamping:no heating is required, a set of corresponding concave and convex molds ensure direct mold formation.

Step 3: Filling

Once the mold is formed, the material is filled into each pocket from the filling station.

Step 4: Sealing

Soon after filling, heat sealing needs to be covered the filling material. In the case of pills, an aluminum foil is used. Heat sealing is achieved by two types, for e.g rolling types and plate pressing types.

Step 5: Trimming

Trimming is done to clear the corners and to make them in proper shape.

ADVANTAGES

- Freshness

Each pill is packed in an individual pocket ensuring easy access and fresh product when opened. - Good Protection

Pills are protected from moisture, light, dust, chemical and physical effects. Hence 100% protection to provide you with a better product. - Accurate Dosing

A pre-determined product is packed in molds that offer uniform dosing. - Pills Visibility

It offers clear visibility of the pills for consumers and retail display, also the product itself is protected from tampering or damage.

STRIP PACKAGING MACHINE

It is the most suitable machine to seal and pack solid dosage formulations. It has the capability to pack pills of different shapes and sizes with materials like aluminum, cellophane, polythene or any sealing material. A strip packaging machine offers the pharmaceutical industry with maximum barrier properties against humidity, light, and other detrimental effects.

In terms of protection, strip packaging and blister packaging have the same profile. The difference between these two packagings is that the strip cannot have thermo-form or cold form cavities.

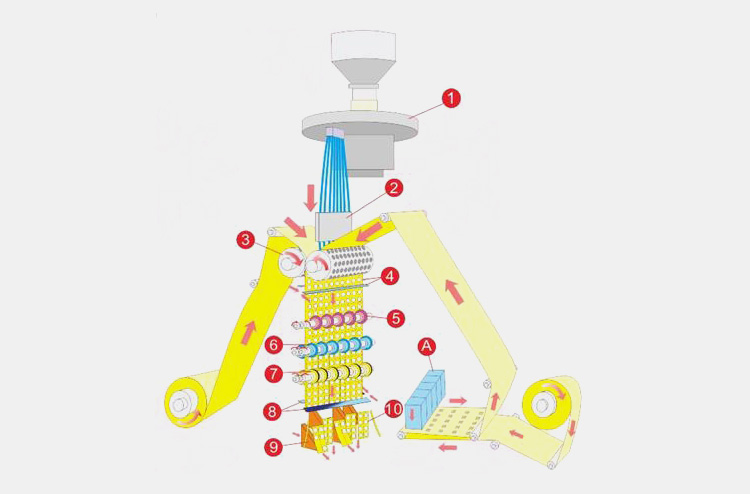

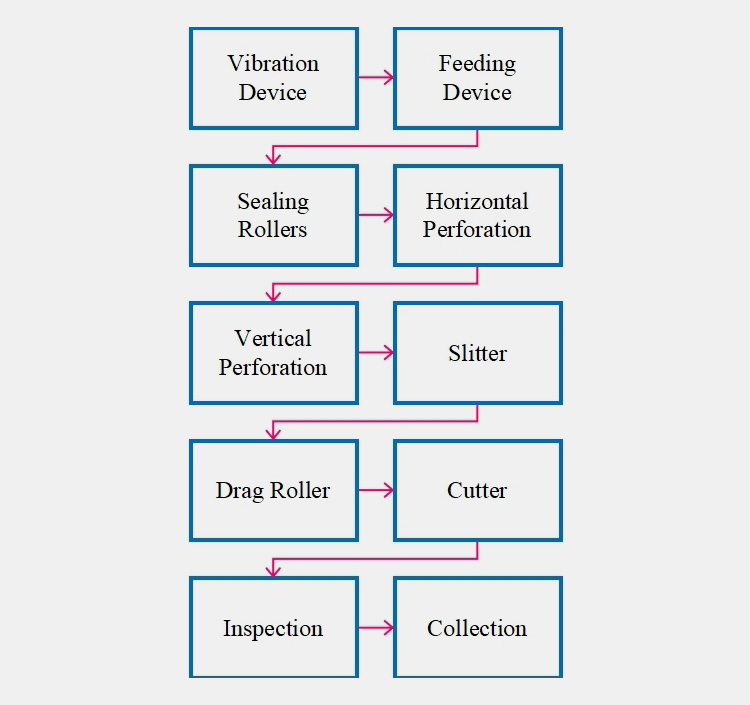

WORKING PRINCIPLE

Step 1: Vibration Device

With help of vibration, the material is transferred from the feeding tube to the feeding device.

Step 2: Feeding Device

The feed device is meant to transfer material into the pocket of sealing rollers.

Step 3: Sealing Rollers

Two tempered sealing roller seals two strips of the aluminum film.

Step 4: Horizontal Perforation

For easy access to a pill, straight-line perforation is applied via horizontal perforation.

Step 5: Vertical Perforation

A vertical perforation is applied to have four-sided perforations for an easy rip of aluminum foil.

Step 6: Slitter

Slitter ensures 100% perforation around the strip

Step 7: Drag Roller

After perforation sealing is checked via drag roller for perfect packaging.

Step 8: Cutter

The packed aluminum strip is cut according to the required number.

Step 9: Inspection

It rejects the miss-feed strips and accepts the correct one.

Step 10: Collection

The final product is collected.

A. Coding

A hot stamp is applied before sealing that prints, expiry, logo, date of manufacturing, etc.,

ADVANTAGES

- Protection

High-level protection is offered to pills, especially those that are hygroscopic in nature e.g., aspirin. - User Friendly

An automatic strip packaging machine requires just protocol input in the PLC unit while the rest of the job will be performed by the machine itself. - Product Originality

A strip packaging machine ensures that pills are stable against physical and chemical harm till it reaches in patient’s hand. - Tempered Evident Sealing

An intact sealing surrounds the product giving a surety that the product is tempered evident.

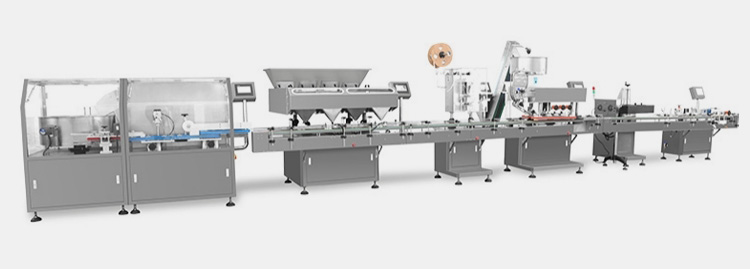

BOTTLE PILL PACKAGING MACHINE

When you convert man’s hour into money, you will be surprised to know how expensive manual bottle packaging is. A bottle pill packaging machine is popular equipment that counts and pack a wide range of pharmaceutical pills. This is a widespread technological solution that senses the presence of pills and ensures accurate packaging into bottles or containers. This is a multi-tasking machine. Some machines are designed with a dessicator inserting option, whereas many of them are created with sensors for weight checking, inspection or detecting faulty tablets, etc.

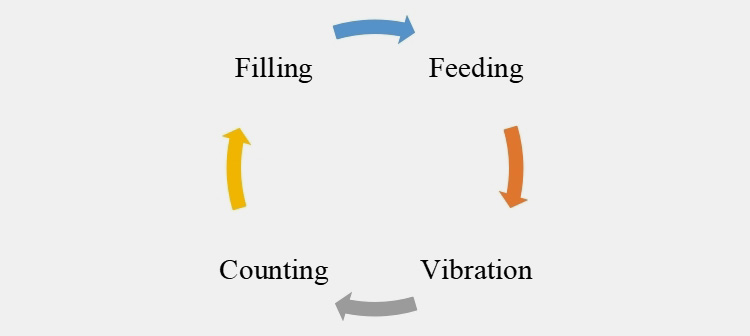

WORKING PRINCIPLE

The working principle of the bottle pill packaging machine is discussed below:

Step 1: Feeding

Pills are fed into the hopper and then transferred to the vibratory unit.

Step 2: Vibration

With the help of vibration, pills are slowly and gradually transported in a clockwise direction toward the sensor.

Step 3: Counting

Pills while passing through the infrared beam inside the counting unit obstruct the beam which is registered as per count.

Step 4: Filling

Each pill is counted and transferred into the bottle via filling nozzles.

ADVANTAGES

- Accurate Detection

The bottle pill counting machine is designed with sensors and alarms that ensure accurate detection of even a dust particle, broken bottle, or chipped pills. - Bulk Quantity Production

It is capable to manage the pills in bulk quantity in no time. - Little Human Monitoring Required

Automatic bottle pill counters are highly efficient machines that require little human inspection.

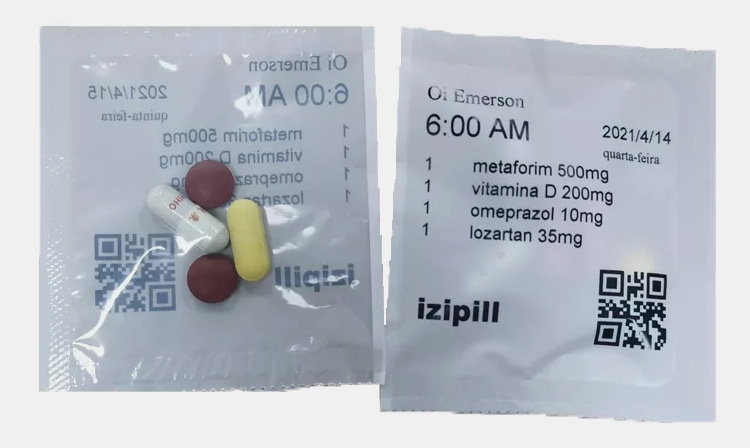

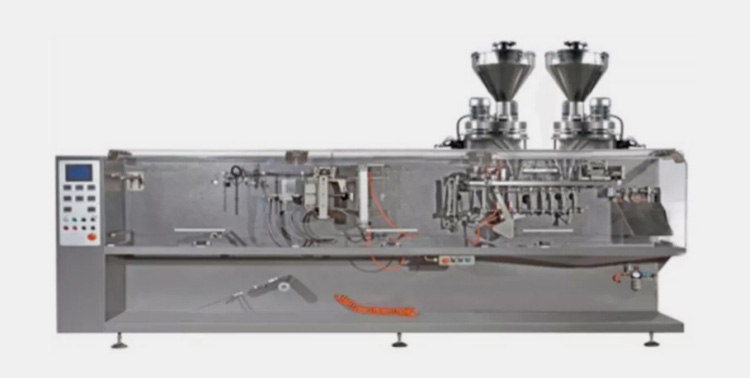

POUCH PACKING MACHINE

Apart from strip or blister packaging, a pouch is also versatile way to secure pills. It is easy to open and gives you 100% secure packaging. A pouch packing machine is created to produce three or four sides sealing around the pills to protect them from unwanted hazards. From unit dose to multi-doses, the pouch packaging machine is efficient enough to give you an economical solution. Moreover, the machine is available in various forms to pack powders, granules, viscous, and other associated formulations. The major structure of the machine for such products is the same except hopper, e.g., auger filler, volumetric piston filler, cup filler, etc.,

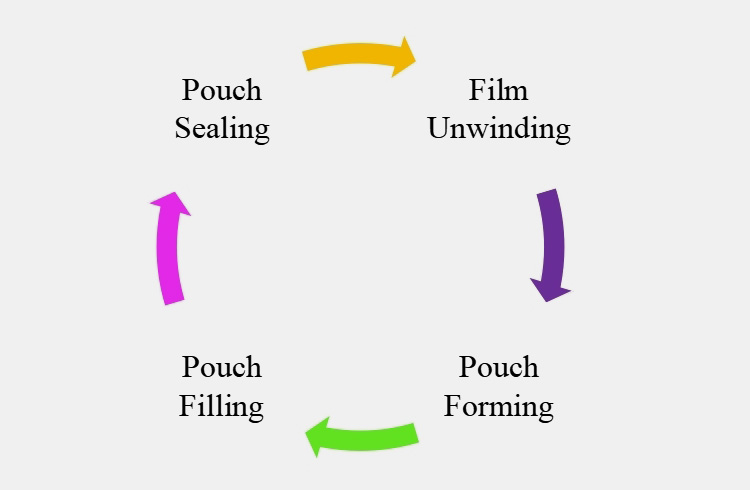

WORKING PRINCIPLE

The fully automatic pouch packing machine is designed to give untouched product filling into assigned pouches. This is simply performed by four basic steps:

Step 1: Film Unwinding

The wrapped film is unwound by rollers and the dancer’s arm to allow smooth film for bag formation.

Step 2: Pouch Forming

A film moves to a pouch forming station where film edges are sealed by sealing jaws side by side.

Step 3: Pouch Filling

In this step, the filling product is dropped down into an opened pouch one by one.

Step 4: Pouch Sealing

As top edges of pouches join together with the help of ultrasonic or heat sealing.

ADVANTAGES

Labeling

Pouches are designed with aesthetic labeling that contains identification, logo, extra information, as well as artwork to enhance appearance.

Storage of Materials

The pouch packaging machine offers high storage to your material via creating pouches of various sizes.

Improved Shel Life

Pouches are created by a flexible barrier that protects the pills against moisture, photodegradation, and oxidation, hence minimizing the risks of spoilage.

Easy to Transport

The pouch packaging machine offers a cost-economical solution with various packaging styles, such as square, rectangular, three- or four-sided sealed packs. You can easily transport your medication because this packaging occupies lesser space. That’s why a pouch packaging machine is a popular way out.

Ⅱ.What Pill Packaging Machine is Best for you?

Looking for a good solution for a pill packaging machine? For this, you need to work on assessing the production line, goals, process working capacity, type of packaging material, and per day requirement. Globally, competitive manufacturers offer an amazing range of pill packaging machines that will suit any company or upgrade the medication packaging process.

Mentioned below is a summarized chart demonstrating major parameters for pill packaging machines.

Blister Packaging Machine

DPP 80 Aluminium PVC Flat Plate Blister Packing Machine

| Production Capacity | 1980 plates/hour (value may vary machine to machine) |

| Punching frequency | 10-33times/min |

Strip Packaging Machine

Aipak APK-SP400

| Packing Material Specification (mm) | PVC for medicine:0.05-0.1×220 AL-plastic combined film:0.05-0.1×220 |

| Production Capacity pcs/h) | 20000-120000 |

Bottle Pill Packaging Machine

Product model APK-A160-16

| Machine Output | 50-90 bottles / min |

| Applicable bottle type | Round, square, and shaped bottles |

Pouch Packing Machine

APK 180T Horizontal 3-4 side seal

| Packaging Speed | 40-60 PPM |

Conclusion

The pill packaging machine is of great value for pharmaceuticals and other industrial usages. ‘What Are The Pill Packaging Machine’ is an informative guide specially created to answer your basic questions. If you have any needs, please contact us for a free consultation and quotation!

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours