Types Of Softgel Encapsulation Machine For Pharmacy

Softgel encapsulation machines occupy a central place in the formulation of softgel capsules. The encapsulator has come a long way since its invention in 1934. Today, the modern softgel encapsulation machine is designed with futuristic technology. Furthermore, it is devising an elegant way of carrying unpleasant medication in the body of the sofgel capsule.

Interested in establishing a dedicated line for manufacturing softgel capsules? First, take a look at various kinds of softgel encapsulators present in the market. The types of softgel encapsulation machine for pharmacy brings extensive information required to select a suitable kind of softgel encapsulators for your business.

Table of Contents

Ⅰ.What are the various types of softgel encapsulation machines for pharmacy?

Softgel encapsulation machines used in pharmacy are divided into two basic types based on the level of sizes.

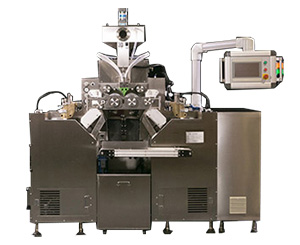

Small Scale Automatic Softgel Encapsulation Machine

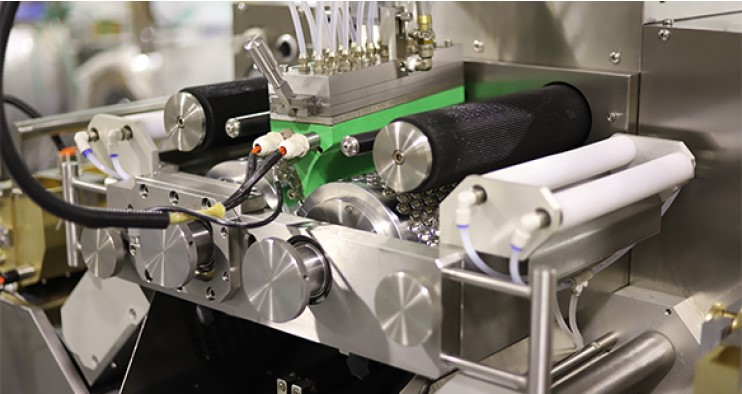

Laboratory Based Softgel Encapsulation Machine For Pharmacy- Picture Courtesy- Aipak

This equipment offers a better working solution for small scale production e.g laboratory, R&D, or small businesses. This is an economical machine, with robust outcomes and easy to operate with a lower chance of error. Such machine can give production output approxemately 2000capsules/hour.

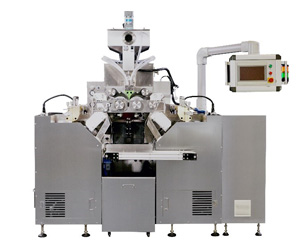

Large Scale Automatic Softgel Encapsulation Machine

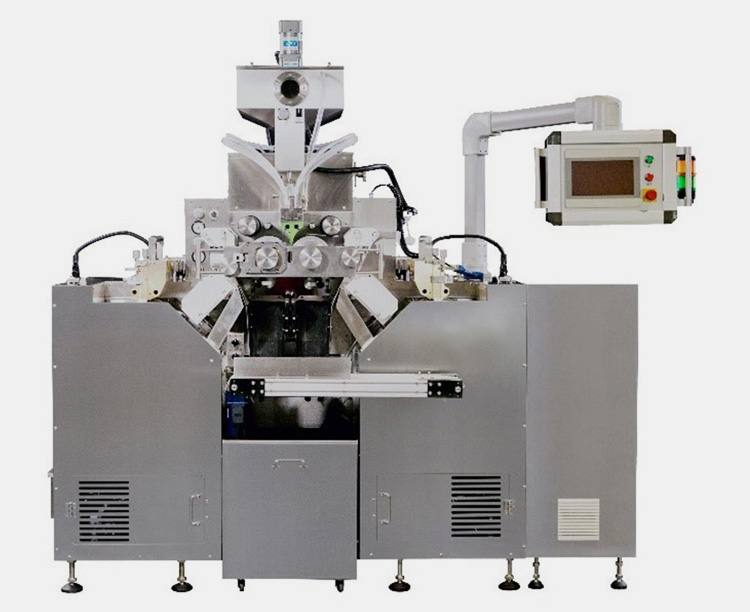

Large Scale Automatic Softgel Encapsulation Machine For Pharmacy- Picture Courtesy- Aipak

These machines are fully capable for functioning without need of human assistance. Processes like material loading, filling, sealing, and discharging are carried out by machine autonomously.

Operators simply have to program parameters on touch screen. These encapsulators are excellent choice for large production because of its large production output, self-diagnosis and cleaning, and less product wastage. Such type of machines can generate work output up to 6000softgel capsule/hour.

Ⅱ.What are the structural components of types of softgel encapsulation machine for pharmacy?

For every manufacturer, it is mandatory to know about the basic components of the softgel encapsulation machine. Also, its potential role in the manufacturing of softgel capsules, Information about basic parts are penned below:

| Material Filling Pump

Present beneath hopper and are used to pump materials to injection wedge via tube. This robust structure is made up of stainless steel |

|

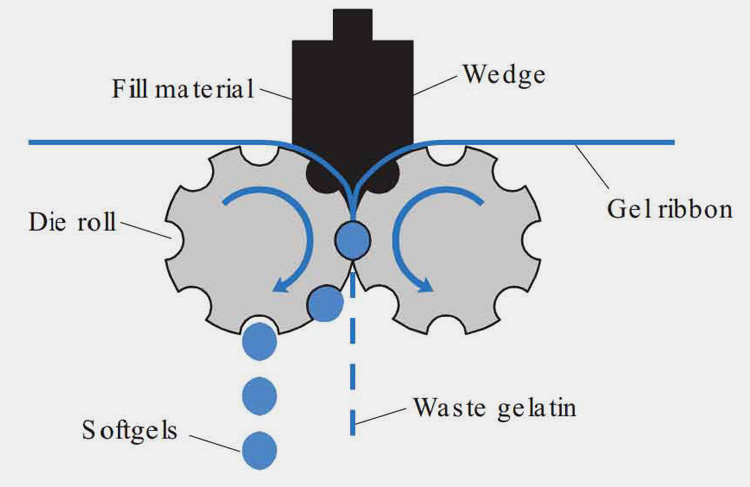

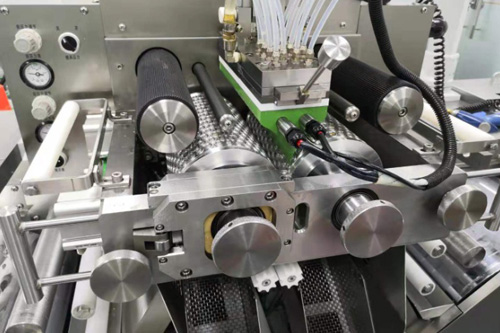

| Injection Wedge

This part is vital in the processing of material because it raises the temperature of material up to the optimal limit. The temperature is controlled through sensors. The injection wedge has a water or electric heating system. |

|

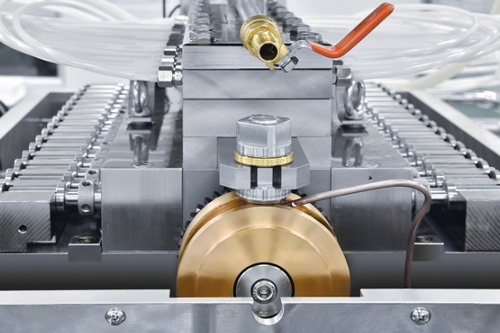

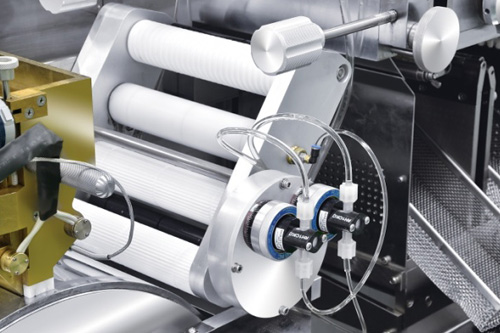

| Die Rollers

The size and shape of softgel capsules are determined by die rollers. These are formed from aluminum and are employed for pressing molds. These rollers also have cavities for reducing gel intensity. |

|

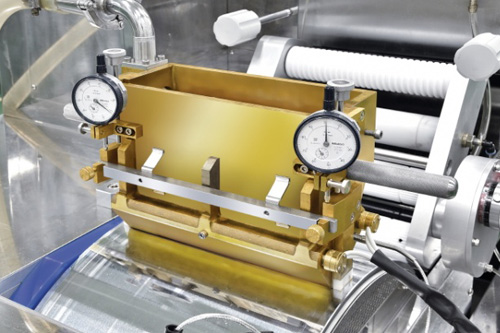

| Spreader Box

Located on both sides and is used to spread gelatin to form a thin coating for encapsulation. |

|

| Cooling Drum

This part is comprised of a fan or water-operated system and reduces the temperature of gelatin coating. |

|

| Lubrication Rollers

They lubricate gelatin to prevent damage. It is necessary for ensuring the tightening of gelatin. |

|

| Control Panel

This part is like the brain of a machine. It regulates and manages all the processes involved in encapsulation. By means of PLC commands for the operation of a machine are programmed. |

|

Ⅲ.What is the working principle of types of softgel encapsulation machine for pharmacy?

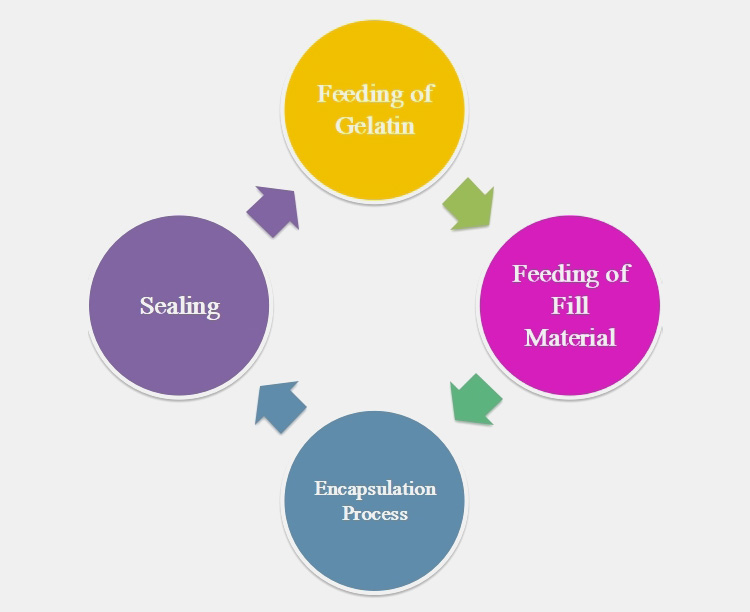

The core operational principle is almost similar in all three types of softgel encapsulation machines employed in the pharmaceutical industry. Step by step guide is detailed below for a thorough understanding of their work.

Feeding of Gelatin

Molten gelatin is pumped into the machine and spreader boxes are employed for forming a thin layer or ribbon of gelatin on either side of the machine.

Pouring of Filling Ingredients

The fill material either in paste or liquid form is poured inside the hopper through which these flow inside the injection wedge.

Encapsulation Process

The ribbons of gelatin are passed over a set of rollers. Simultaneously, fill materials are forced between two ribbons. This causes gelatin to move inside the die pockets. With the rotation of die rollers, two ribbons are covered with fill material encapsulated inside. The die cavity determines the shape and size of softgel capsules.

Sealing

Afterward, softgel capsules are hermetically sealed and are removed from the machine. This sealing of softgel is done by the pressure of die rollers at a high temperature of 37-40° C.

Ⅳ. What are the features of types of softgel encapsulation machines for pharmacy?

Softgel encapsulation machines are worth of investment due to being a cost-effective solution for manufacturing lines because these have the following features.

| These machines are manufactured with stainless steel which ensures hygienic design and durability. |

| This equipment has a customized touch screen interface that aids in the efficient programming of parameters. |

| Softgel encapsulation machines are instantly dismantled due to the quick disconnect feature of components. |

| Machines are designed according to cGMP guidelines and are offered with dust extraction components. |

| Low gelatin wastage because of extremely sensitive temperature control. |

| Lubrication systems are present in softgel encapsulation machines to decrease white oil use. |

| Injection pumps have V-type polytetrafluoroethylene(PTFE) sealing for precise sealing of capsules. |

| Electronic control and servo drives in encapsulators provide constant movement. |

Ⅴ.What is the importance of types of softgel encapsulation machines for pharmacy?

Softgel encapsulation machines are high in demand in the pharmaceutical industry. This is because of certain benefits that we have discussed below:

| Precision | The encapsulators ascertain an accurate and consistent dose of liquids or pastes inside capsules. This job is difficult to achieve with the help of manual labor. |

| Production Efficiency | Softgel encapsulators have a high production capacity and can produce up to 500,000 to 900,000 softgel capsules per hour. This high output translates into more capsules in the market and more profits. |

| Labor Cost | Softgel encapsulation machines autonomously operate, this lowers the number of operators managing the machine thus decreasing your labor wages. |

| Product Wastage | Human operators can make mistake in the preparation and filing of softgel capsules that leads to product wastage. Softgel encapsulation machine also cut down your product wastage due to less human involvement. |

| Hygienic Construction | These machines are furbished with dust extraction devices that minimize the chance of drug contamination. |

| Airtight Sealing | Softgel encapsulation equipment seal capsules with hermetic sealing that prevents the entry of impurities inside the softgel capsules. |

Ⅵ.What type of softgel encapsulation machine is suitable for your manufacturing

Softgel encapsulation machines are used to form many products such as

- Omega-3 fish oils softgel capsules

- Multivitamin softgel

- Herb supplements

- Skincare

- Fish bait

- Bath oil

- Insecticides softgel for pets

- Cosmetics products

A variety of softgel encapsulation machines exists in the market differing in design and production speed. Opt for that machine that is appropriate for your production based on:

- Space Availability

- Output capacity

- Budget

- Noise level

- Raw material

- Energy consumption

- Regulatory compliance

Ⅶ.What is the future forecast for types of softgel encapsulation machines for pharmacy?

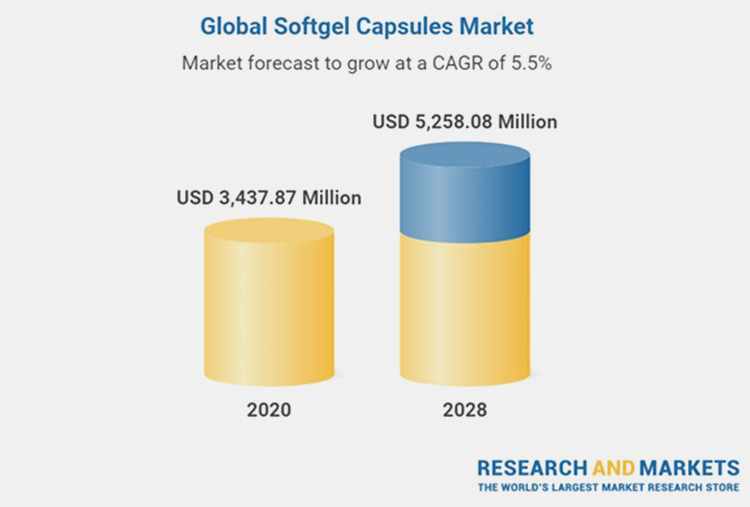

More and more people are buying vitamin and mineral supplements in form of softgel capsules because of the increase in health awareness post-pandemic. As a result demand for softgel encapsulation machines has also surged.

It is projected that in 2028, the market for softgel manufacturing machines will reach to the US $544.5 Million from US $ 270 Million in 2022 with a CAGR of 12.4%.

With a share of greater than 35%, North America is the largest manufacturer of softgel encapsulation machines. The second-largest market for softgel encapsulators in Europe and the Asia Pacific has combined shares of 55%.

Conclusion

Softgel encapsulation machines are the need of a manufacturing line that deals in the formulation of softgel capsules. These machines are readily demanded due to the increased production of softgel capsules. ‘Types Of Softgel Encapsulation Machine For Pharmacy’ review article is basically highlighting significant factors you must know before making a purchase.

If you want Technical Support related to equipment or looking for buying guidelines, We welcome you to contact us.

Don't forget to share this post!

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine