Top 5 Machineries For Producing Cosmetic Cream

Creams are semi-solid formulation composed of an oil and water mixture. The consistency of creams varies between liquid and solid materials.

The cosmetic business is extremely profitable as it gives you an amazing success rate with high-profit margin.

Today, everyone is seeking for good care of personal hygiene and skin by using such products. Thus, you’ll have a good scope for this enterprise.

Whether a pharmaceutical or cosmetic creams both requires the same technique and machinery to develop them.

In this review articles, we have present topmost equipment involved in manufacturing cosmetic cream. Read them one by one to learn their importance in the cream manufacturing process.

Table of Contents

Ⅰ.Vacuum Emulsifying Mixer

Vacuum Emulsifying Mixer is a well-structured machine used for mixing high viscosity material in order to achieve high speed homogenization.

This mixer machine offers high quality mixing of product ingredients due to its well-structured design. The parts of this machine include a homogenizer and stirrer of two types, middle blade and residue scraper to clear the stuck material on the inner surface of the mixer.

Another important component is “vacuum pump” which makes material air-free resulting in the mixed material being spongy, neat, moving and glossy.

AIPAK Vacuum Emulsifying Mixer

1.Working Principle

Oil and water after heating suck into the vacuum emulsifying container. During mixing, processing materials are compacted, reduced in size, and blended by the function of rotary plate, fixed cutting cover and high-speed cutting wheel. This process is continuously repeated until the ingredients reduce to size 200 nm- 2um.

2.Benefits

- A vacuum emulsifying mixer is an advanced machine with distinct features to ensure high homogenization.

- This machine has different mixing systems such as ribbon helical, single way, double way

- This mixer can be utilized for emulsification at rotation speed upto 4,200 rpm and can provide shearing fineness upto 0.2-5μm.

- This mixer is easy to clean due to the lifting system in the emulsifying container lid.

- This mixer makes the processing materials aseptic due to the presence of vacuum defoaming.

3.Applications

Mixing is an essential process in a large number of industries. Therefore, the vacuum emulsifying mixer is considered as the central equipment which is mainly utilized to attain uniform mixing in the following industries.

Pharmaceutical Industry

The vacuum emulsifying mixer is commonly used in the pharmaceutical industry for manufacturing products like gels, lotions, creams, ointment, and products like suspensions.

Chemical Industry

The vacuum emulsifying mixer is widely used in manufacturing products like washing powders, liquid dishwashers, detergent, paints, dyes so it induces high shear mixing properties.

Food Industry

This machine plays a significant role in the food industry for the preparation of products like mayonnaise, jam, ketchup, margarine, chocolate, and spread.

Fertilizer Industry

A vacuum emulsifying mixer is used in the fertilizer industry for seed coating, herbicides, and pesticides production.

Paint Industry

A vacuum emulsifying mixer is used in the manufacturing of paint that required high shear emulsification for a proper blend.

Petrochemical Industry

A vacuum emulsifying mixerhas the ability to hold and control heavy solutions and gives them easy and stable operation by high shearing emulsification.

4.Why Do You Need a Vacuum Emulsifying Mixer?

You need a vacuum emulsifying mixer for high shear emulsification for the distribution of oil phase into water oil rapidly and evenly. The material is processed in his machine by rotor and stator with a strong motion.

Therefore, This machine is a must-buy instrument to get a strong emulsifying effect in cosmetic creams.

5.Next Step

After the emulsification process, you will fill your product in the assigned containers or tubes. Some manufacturers select jars for dispensing while some choose tubes. You can’t use the same machine to execute these two distinct functions.

So here you will be needed either a cream filling machine (hand cream, facial products) or a tube filling machine (eye creams, primers). We have discussed both of them in our next step.

Ⅱ.Cosmetic Cream Filling Machine/Tube Filling Machine

A : Cosmetic Cream Filling Machine

This machine is highly appropriate for filling solutions or materials with moderate viscosity that include liquid dosage forms, and cosmetic products and securing them with a cap. This is an integrated system manufactured in several ways capable to close the opening using plastic, or metal caps.

Cosmetic Cream Filling Machine

1.Working Principle

Photoelectric sensor detects empty bottles. This machine is equipped with programmable logic controller (PLC) system which holds the mouth of an empty bottle and allows materials to fill in it. It uses vacuum technology for capping on the bottles which is regulated by servo motor.

2.Benefits

- This machine is highly appropriate for filling hot drinks because it operates at high temperatures in the range of 55-95ºC.

- At the time of changingthe bottle, mechanical cream filling machines pause the air conveyor which is highly efficient.

- The filling operation is very smooth, fast, and accurate.

- It offers efficiently sealed products, minimizes product loss,and prevents materials contamination.

- Easy to operate, the automatic system with frequency converter, programmable logic controller (PLC) system, and convenient touch control system.

3.Applications

This machine is commonly utilized in numerous industries including:

Pharmaceutical Industry

Every Pharmaceutical item requires cream filling machines to perform a designated function of securing medicines under steady pressure.

Chemical Industry

Cream filling machine is used for thew e chemical products to fill safely, and protect them against photo-degradation, growth, safety, and prevent leakage.

Cosmetic Industry

Every cosmetic manufacturing unit requires cosmetic filling machine to achieve an efficient filling properties for their products.

Food Industry

Every food and beverage system required filling and capping of the products. Today, every manufacturer utilize automatic filling and capping machine to achieve this job.

4.Why Do You Need a Cream Filling Machine

This machine offers a volumetric filling with a high level of accuracy with securing abilities. Every good manufacturing department needs this machine for the cosmetic production line to avoid product spillage, chemical, and physical reactions.

B: Tube Filling Machine

The multi-step operation of this tube filling machine is fully automatic ranging from filling tubes with less or more viscous liquids to the printing of product details on them.

Process steps are feeding of the tube, photoelectric mark track, coding of date, batch number, trimming of the tube and final product release.

This machine is primarily utilized for filling gels, creams, paste, or related fluids into laminated and polyethylene tubes followed by sealing of tubes with hot gun technique. This machine is equipped with a programmable logic controller (PLC).

The operation of this machine is quite easy and stable throughout the process due to its durable structure, additionally, it offers high accuracy with low noise.

AIPAK Automatic Tube Filling & Sealing Machine

1.Working Principle

The working setup of this machine involves mechanical tube feeding, detection of tubes by marking distinctive color, mechanical filling, heating using hot air, sealing, and coding of date, trimming/cutting, and product release.

2.Benefits

- An automatic tube filling machine isan easy-to-operate instrument.

- High-accuracy photoelectronsmeasure minimizes the possibility of chromatic irregularity.

- Accurate adjustment is possible with ease due to the digital display that makes it suitable for the production of multiple products.

- The automatic alert system if there is low pressure or error in the tube position, or if the protective door is accidentally open.

- It is made up of stainless steel and satisfiesGMP Standard.

3.Applications

These machines are commonly utilized in numerous industries including

Pharmaceutical Industry

Cosmetic cream filling machine/tube filling machine are popular equipment pharmaceutical industry for filling products like viscous creams, ointments, and pastes.

Chemical Industry

A tube filling machine is used in the chemical industry to dispense chemicals products correctly with no danger. For instance, caustic products, bases, acids, etc.,

Food Industry

The food industry, where the processing of viscous products is commonly produced in marketed. These products usually required a tube filling machine for safe, accurate, and rapid dispensing.

Cosmetic Industry

Face lotions, foundation, facial creams, eye creams, etc., are the popular preparations of the cosmetic industry. Hence, an advanced featured tube filling machine is ideal to deal with sticky, viscous, and semi-viscous substances.

4.Why Do You Need a Tube Filling Machine

Processing viscous substance like cosmetic creams comes with distinct challenges. You will always need a tube filling machine in order to fill them accurately. This machine offers you a lower package cost, reduced labor cost, high- output, and product safety.

5.Next Step

It is time to apply labels over your manufacturing cream. For this, every industry requires an automatic labeling machine for products like containers, tubes, bottles, jars, etc. Read on Step 3 to know more about the premium labeling system.

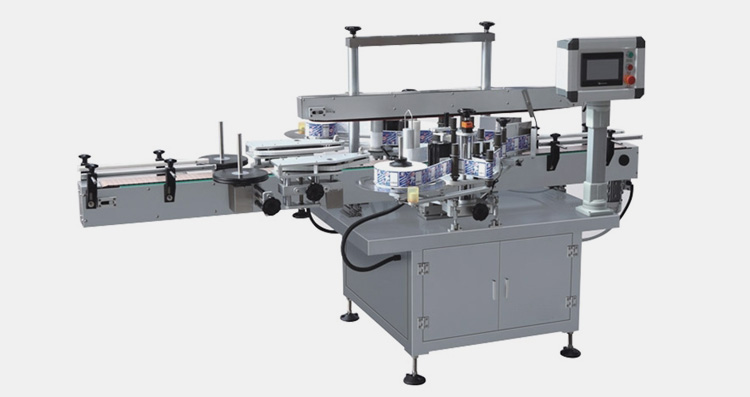

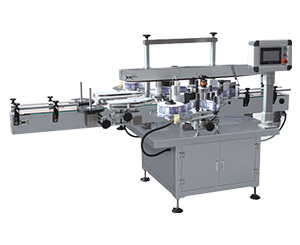

III.Automatic Labeling Machine

An automatic labeling machine is a type of equipment utilized to label a packed product. They are printed and capable to stick over the container with a unique logo and required description. For instance, ingredients, date of manufacturing, expiry date, brand image, etc.,

Setup and maintenance of automatic labeling machines are quite simple. It uses a PLC system, touch screen, and servo motor. Parameters within range can be modified randomly such as the setting of work number, display, counting, etc. There is a detection system in this machine that automatically signals the absence of a bottle hence, it does not send labels for subsequent labeling.

AIPAK Front & Back Sticker Automatic Labeling Machine

1.Working Principle

Unlabeled bottles/containers enter the machine through the hopper and move in parallel with their respective labels resulting in the right label stick on the bottles/container. There is an in-feed system in the machine which provides the right spacing and ensures the high precision of the process that leads to product discharge.

2.Benefits

- The labeling step is operated under photoelectric control therefore quite stable and accurate. It also allows random adjustment of labeling positions.

- The label position is highly accurate throughout the batch due to the use of a pre-labeling system.

- This machine guarantees the coding quality and precisely controls the label length and ensures label size uniformitythroughout all products.

- There is variation in the design of labels for different products, this machine satisfiesmultiple label styles for a wide range of bottles designs.

3.Applications

It is highly appropriate for labeling on square bottles, flat bottles, round bottles, and other shaped bottles designed for specific needs. Automatic labeling machines are commonly utilized in numerous industries including:

Pharmaceutical Industries

Having proper labeling with essential information is compulsory for the marketing of pharmaceutical products.

Chemical Industry

How would you know if a container holding corrosive product inside? Of course by finding a label with special warning instructions, date of manufacturing, expiry, precautions, and dilution methods.

Food Industry

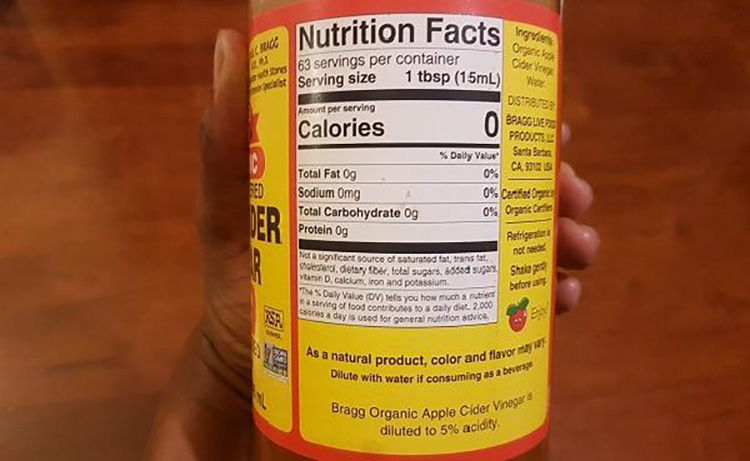

The food industry utilizes a labeling machine to give an FDA information chart on its label that contains nutritional facts on it. For instance, serving size, calories, protein content, etc., Besides this, you may find the composition of the product by reading a label in a product.

Cosmetic Industry

In the cosmetic industry, an automatic labeling machine is used to state the identity of your product. Besides this, a description of the product, its names such as gel, mascara, and the nature of the product are also mentioned on a label.

4.Why Do You Need An Automatic Labeling Machine

You need a labeling machine for your production line to apply labels over various items such as containers, or other assigned jars. Some labeling machines are not only used for dispensing but also help in printing the labels.

5.Next Step

Packaging of manufactured products into a carton is an integral step that requires a cartoning machine widely used in production departments on a large industrial scale.

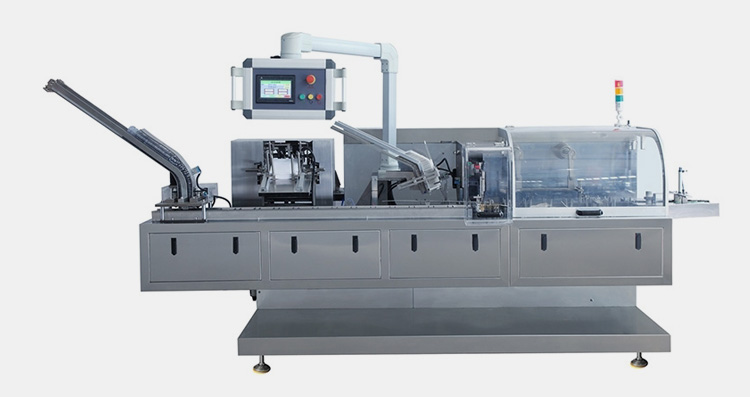

Ⅳ.Cartoning Machine

A high-speed cartoning machine is utilized for products for which high output is required. This machine operates in two modes, independently or as a component of the production line such as a blister packaging machine.

This machine is made with advanced technology and it is combined with pneumatic-photo-electro-mechanics.

AIPAK Horizontal Boxes Packaging Automatic Cartoning Machine

1.Working Principle

The base of the carton is fixed to a vacuum suction/sucker, the front and back end are pushed by the pneumatic system in order to transfer the carton in the right direction to the loading bay. Products are loaded into the carton then the machine folds the carton's ear by the cam linked to the motors including push plates on each sideways of the bar.

2.Benefits

- This machineuses a programmable logic controller (PLC) system, operates athigh speed, and moves continuously in a horizontal position.

- The whole setup is automatic including folding of the leaflet, the opening of a carton, wrapping, and closing of carton.

- Easy and stable operation, and offera wide range of filling capacities

- There is a detection system that automatically detects errors during the process and displays

3.Applications

This machine is commonly utilized in numerous industries including:

Pharmaceutical Industry

Cartoning machine commonly used in pharmaceuticals to pack the containers, bottles, blister packs, syrups, inhalers, sachets, etc.,

Chemical Industry

In the chemical industry, packaging products that deliver protection and security are of paramount importance. The carton machine is designed to offer these features to its end-users.

Cosmetic Industry

Cartoning machine is essential equipment for the cosmetic industry for custom packaging cosmetic boxes to improve your brand.

Food Industry

For the packaging of food items such as biscuits, cakes, pizzahs, cookies, as well as processed food requires automatic cartoning machine for efficient packaging and transport.

4.Why Do You Need Automatic Cartoning Machine

A cartoning machine is high speed equipment that offers a flexible packaging line that can improves the work efficiency as well as branding due its safe products distribution property.

Conclusion

Planning on manufacturing cosmetic cream? AIPAK pharmaceutical machinery offers each important feature to run a successful business. Also, you can control their premium quality machinery so easily. You can streamline your life-changing business effortlessly by contacting our high-tech experts Right Now.

Don't forget to share this post!

Cartoning Machine Related Posts

Cartoning Machine Related Products

Cartoning Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine