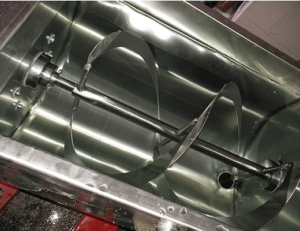

Carbon steel main structure

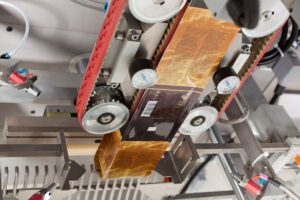

Premade spout pouch feeding

Automatic spout cleaning

Want A Free Consultation

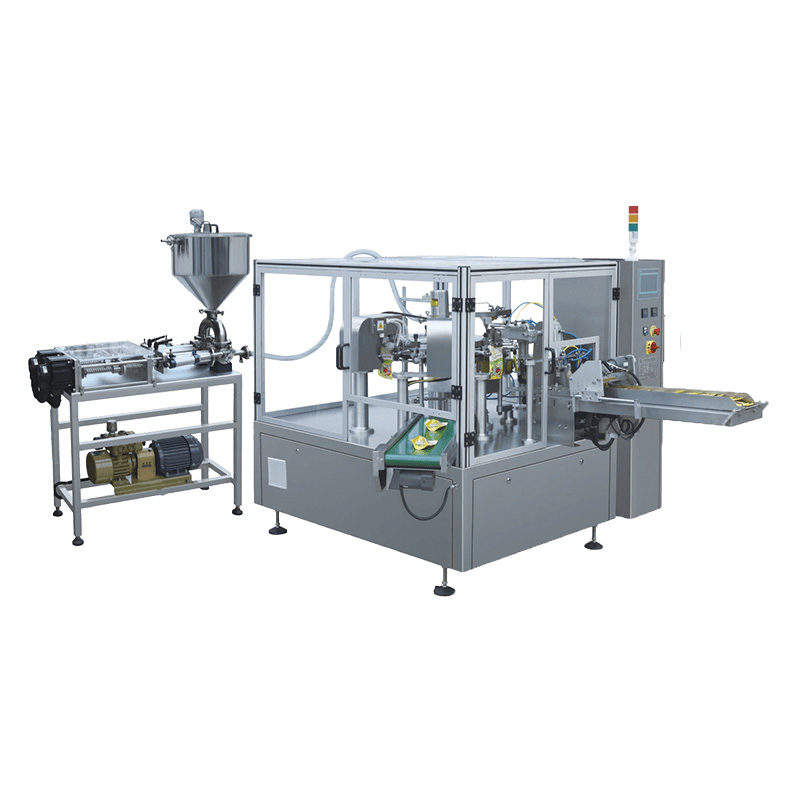

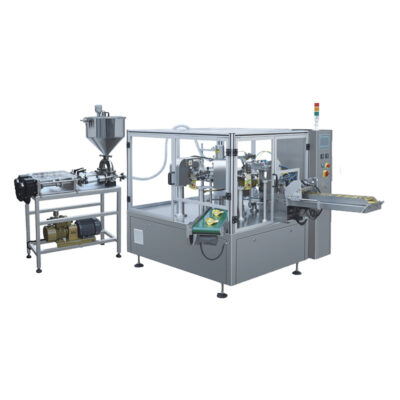

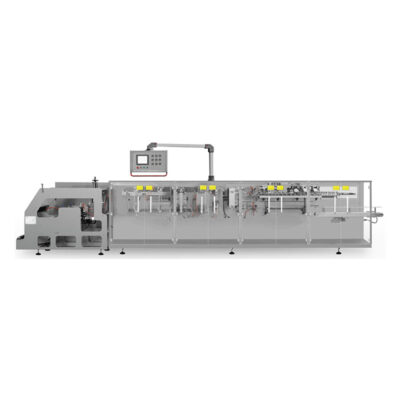

APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

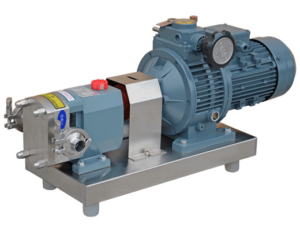

Dosing system

Piston Filler Hopper Rotary Pump

AIPAK APKRL200-Y Liquid premade pouch filling machine is equipped with pistion filler as the dosing system, it is widely applicated to packing liquid and paste, such as detergent, softener, shampoo, shower gel, milk, water, juice, soybean sauce, oil, ketchup, mayonnaise and so on.

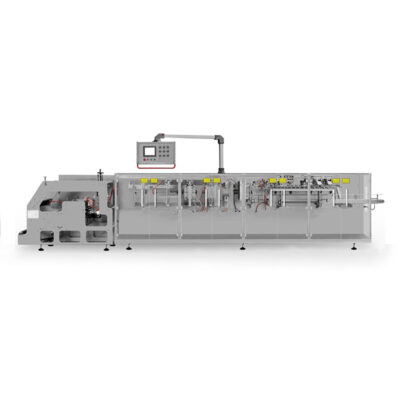

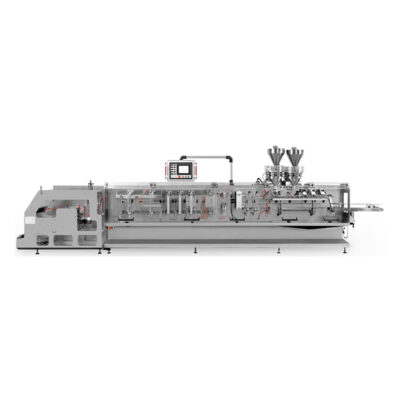

- Model: RL8-200; Pouch width: 80-200mm; Pouch Height: ≤350mm; Speed: 20-60pouches/min;

- Model: RL8-250; Pouch width: 140-260mm; Pouch Height: ≤350mm; Speed: 20-50pouches/min;

- Model: RL8-300; Pouch width: 200-310mm; Pouch Height: ≤450mm; Speed: 20-40pouches/min;

FEATURE

- Easy to operate, SIEMENS PLC and Touch Screen control system.

- Stainless steel housing, parts in contact with the product and bags comply with GMP requirements, guarantee hygiene and food safety.

- Includes Japanese Dry Type vacuum pump for an ideal vacuum suction of the pouch pick up and opening, reliable, low noise and low maintenance.

- Automatic control: non-filled /not sealed/no pouch or in case of pouch opening errors, the pouch can be used again.

- Easy changeover for different pouch sizes. The gripper width can be adjusted automatically from the touch screen panel.

- Wide range of usable packing materials, suitable for multi-layer compound, Aluminum foil, laminating film, Paper laminating film etc.

DATA SHEET

|

Model |

APKRL200-Y |

APKRL260-Y |

APKRL320-Y |

|

|

Pouch pattern |

Laminated film PP/PE Foil |

|||

|

Bag Size |

W:8~200mm L:≤100-350mm |

W:140~260mm L:≤350/450mm |

W:180~320mm L:≤450mm |

|

|

Filling Scope |

≤1000g |

≤3000g |

≤5000g |

|

|

Packing Speed |

20~50bags/min |

10~40bags/min |

5~30bags/min |

|

|

Total Power |

3W |

|||

|

Voltage |

380v 3phase 50Hz |

|||

|

Weight Accuracy |

≤±1% |

≤±1% |

≤±1% |

|

|

Compressed Air Consumption |

0.6m3/min(Compressed air provided by the user) |

|||

VIDEO

CONTACT

Get in touch with an expert

Andrew Yang

Engineer Director

Phone: +86 181 6426 8586