Top 10 Fluid Bed Dryer Manufacturers in Europe

A fluid bed dryer is the finest solution for drying ingredients as it is high-performance equipment as compared to traditional drying methods that are not suitable and troublesome. This equipment is extensive need of the pharmaceutical industry to minimize the moisture content in raw content like powder or granules.

The global statistic states that the year-over-year growth of fluid bed dryers worldwide was estimated at 2.11% in the year 2018 and is accelerating with a CAGR of over 2%. The incremental growth from 2018 till 2022 is estimated to be 70.91 million USD.

| RANK | MANUFACTUER OF BLISTER PACK MACHINE | HEADQUARTERS |

| 1 | Neuhaus Neotec | Germany |

| 2 | COS.MEC | Italy |

| 3 | Loedige | Germany |

| 4 | AIPAK | China |

| 5 | Buss-SMS-Canzler GmbH | Germany |

| 6 | Ventilex | Netherlands |

| 7 | GEA | Germany |

| 8 | TEMA Process | Netherlands |

| 9 | ROMACO | Germany |

| 10 | Glatt | Binzen |

1. Neuhaus Neotec

Company Background & Information

Neuhaus Neotec operates from German soil and provides solutions for process lines installed in food, confectionery, pharmaceutical and biotechnology industries. They have proved to be the leader supplier and manufacturer of these products and have a variety of options in their catalogue.

Since 1991, they have been a part of KAHL group and operate with two plants in Ganderkesee near Bremen and Reinbek near Hamburg respectively. They have an experienced team with specialized work skills, and this is why they have produced number of products and supply them globally.

Key Products

- Fluid Bed Dryer Fascination.

- Batch FB – plants

Recommend Reason

- Precised and adjustable.

- Highly efficient.

- Easy to handle.

- Operations are quick and advanced.

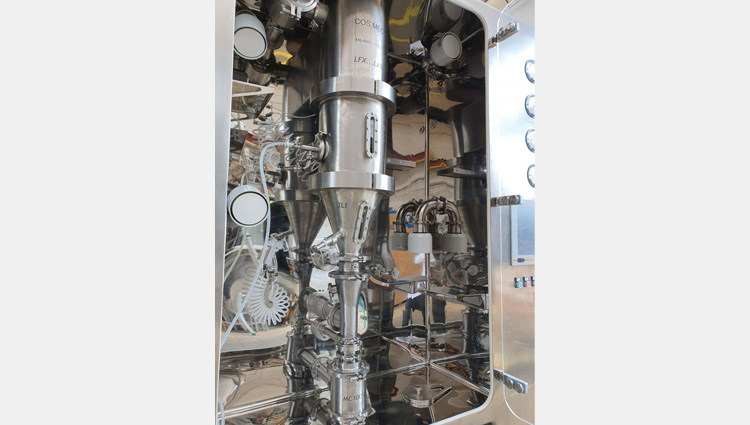

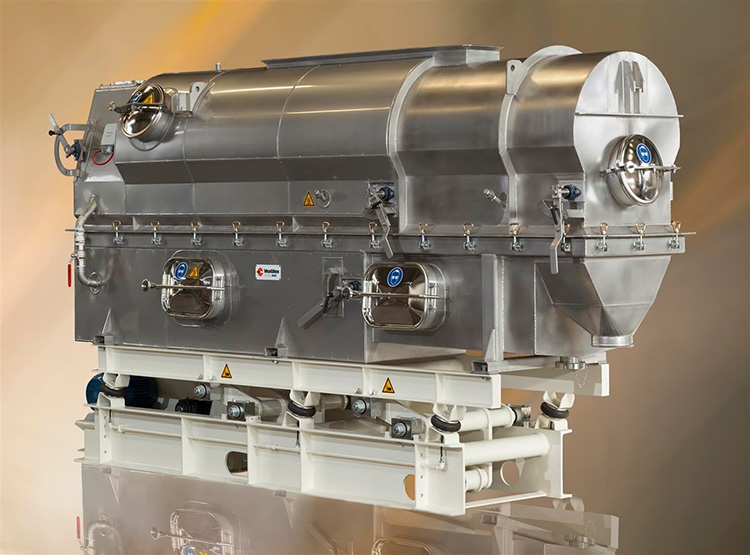

2. COS.MEC

Company Background & Information

With an experience of over 30 years, Cos.Mec has been a manufacturer and global supplier of highly advanced machines incorporated in food, chemical and pharmaceutical companies. Having their headquarters in Italy Cos.Mec is now producing many economical and well-designed products for their global customers.

They have been fulfilling the global standards and parameters in their products and this is why today have recorded a business of 15% improvement in 2021 as compared to that in 2018. Today, Cos.Mec features a number of options to their customers and rapidly spreads its network to the whole country.

Key Products

- Laboratory Fluid Bed

- Fluid Bed Dryer

Recommend Reason

- Easy to handle.

- Continuous fluidization can be carried out.

- Can be moved easily.

- Hepa type outlet filters.

- Uses containers of variable volume.

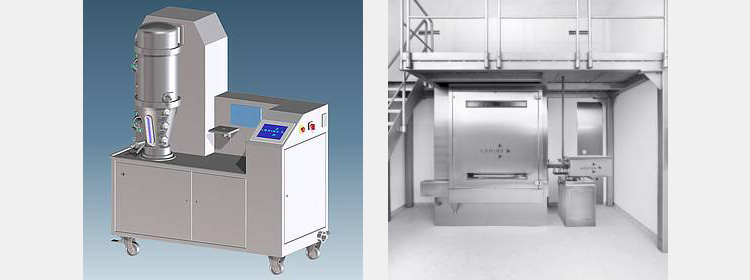

3. Loedige

Company Background & Information

Loedige process technology tends to be the global leader of manufacturing process equipment and systems used in construction, pharmaceutical, chemicals, minerals, food, and environmental application machines. They offer both semi-automatic and automatic machines with a complete installation facility till the smooth running of machines. Based in Germany Loedige has now an experience of over 40 years in producing these solutions.

Key Products

- Fluid Bed Processor (Laboratory Machine).

- Fluid Bed Processor.

- Fluid Bed Dryer LCF for continuous operation.

Recommend Reason

- Additional options for drying and cleaning.

- Top and bottom spray application.

- Cleaning of tanks is very easy.

- Replacement of filters is very quick in process.

- Floors can be used for multiple options.

4. AIPAK

Company Background & Information

AIPAK Pharmaceutical Machinery is China’s leading company specialized in the filling, drying, and packaging machinery supplied across the globe. AIPAK Pharmaceutical Equipment began its journey by manufacturing customized capsule filling machines. Now, for the last ten years, they are best known extensive range of production lines suitable for various fields such as pharmaceuticals, chemicals, foods, research, agrochemical, plastic, and much more.

AIPAK is a top-notch manufacturer of fluid bed dryer that offer particle size reduction technology. They export their innovative machines to more than 100 countries demonstrate an 80% excellent trading profile.

AIPAK is a dedicated firm that produces promising products with superior quality designed by skilled staff. They assure high reproducibility and simple operations. You can get extraordinary services before and after procuring AIPAK’s products. If you’re out of the station; AIPAK offers you remote demos of their product so you can easily facilitate AIPAK’s services from every corner of the world.

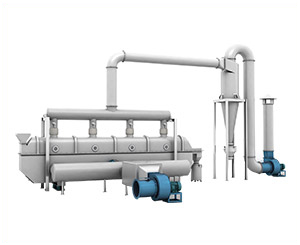

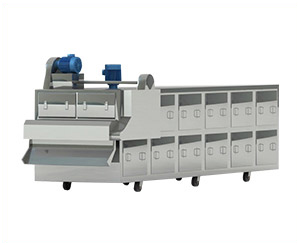

Key Products

The innovative fluid bed dryers of AIPAK are :

- FG Series Fluid Bed Dryer

- LPG Series High-speed Centrifuge Atomizing Pharmaceutical Dryer

- DW Series Mesh-Belt Pharmaceutical Dryer

- ZLG Series Vibration Fluidized Bed Dryer

- SZG Series Double Cone Rotary Vacuum Dryer

- GFG Efficient Boiling Pharmaceutical Dryer

- FL300 boiling granulating Pharmaceutical Dryer

- Model RXH Series Hot Air Circulating Pharmaceutical Dryer

Recommend Reason

- AIPAK fluid bed dryers are ideal for sensitive products as they are accompanied with gentle mixing and drying of delicate ingredients.

- Highly efficient and rapid drying maximum up to 5 to 20 minutes.

- Extremely innovative and user-friendly equipment.

- They offer long shelf-life products.

- You can get uniform heating, high dispersing fans, and saves energy up to 30%.

- Low noise and stable operation.

- Promised and on-time delivery.

- Best services and cost economical.

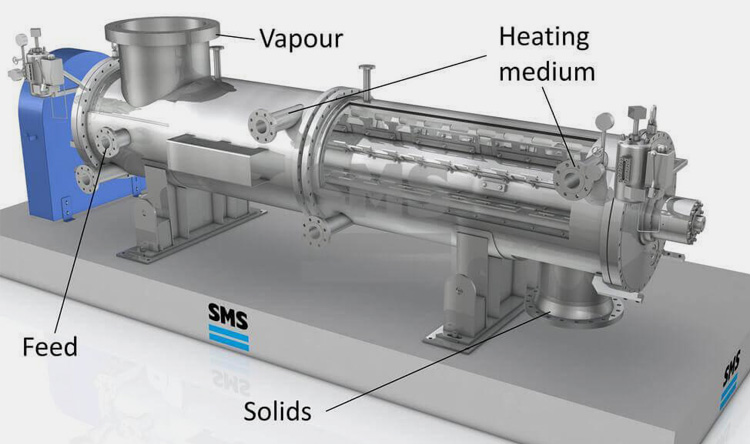

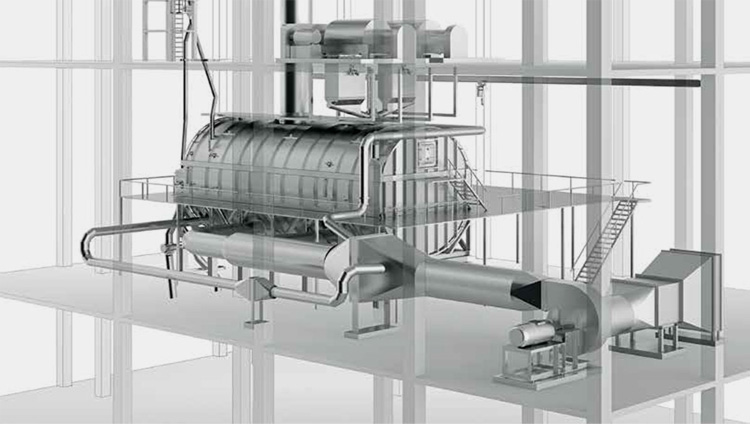

5. SMS

Company Background & Information

SMS inside Excellence claims to be the leader in producing thin-film evaporation technology and also in providing a solution for dying and high viscosity systems. They have been continuously improving with innovative ideas and high precision. They have an experienced staff of over 250 members and all of those are highly efficient in their working abilities. They provide processing and machine support too and with this, they have recorded an annual turnover of 42.5 million euros from the period of 2010-2019 with an increase of 5% every year.

Key Products

- Combined Fluidized dryer technology.

Recommend Reason

- Temperature stress relating to product is very low.

- Fewer workforces are required.

- Plants are smaller and parts are also of small sizes.

- Easy to access machines.

6. Ventilex

Company Background & Information

Ventilex are the leader of manufacturing dying and thermal solutions in Netherlands since 1965. They have been in the top review of global customers due to highly innovative machines and human-friendly process lines.

Ventilex later started their second service in the United States of America for more than 11 years now and market coverage in over 50 years. They have specifically target the customer of pharmaceutical, food and chemical industries.

Key Products

- Ventilex Fluid Bed Dryer For Bulk Processes.

Recommend Reason

- Easy to handle machines.

- Easy to operate.

- Maintenance free.

- Machines are robust and efficient.

- Less consumption of energy.

- Efficient machines.

7. GEA

Company Background & Information

Since 1881, GEA started as metal trading company and later in 1931, GEA started their career in producing dairy engineering technology products. Furthermore, they started making all processing lines for multiple industries.

Today GEA are the largest manufacturer and supplier of Fluid Bed Dryers technology. They have wide range of products in their list and have now spread their business in around 64 countries. They are providing solution in the food and pharmaceutical industry and have reached annual revenue of 4.6 billion euros in 2020. They provide best customer needs with complete installation facility.

Key Products

- Contact Fluidizer Fluid Bed.

- Fluid Bed Dryer (Static).

- Potash Conditioning System.

- Spray Fluidizer.

- Vibro-Fluidizer Fluid Bed

Recommend Reason

- Designed with advanced technology.

- Machines are user friendly.

- Easy to handle.

- Highly advanced processes.

- Combines all types of pharmaceutical and chemical processes.

8. TEMA Process

Company Background & Information

TEMA Process is highly experienced in producing fluid bed dryers used for the drying process of chemical, food, pharmaceutical products and biomass solutions. Other than fluid bed dryers TEMA Process is also experienced in producing machines for sterilization, cooling and pasturing machines.

The company holds a greater number of staff who are dedicated in manufacturing thermal and physical process equipment. They are growing with a rapid pass and are dedicated to in the services they provide to their customers.

Key Products

- Fluid Bed Units.

- Shanking Fluid Bed.

- Static Fluid Bed.

- Vibrating Fluid Bed Dryer.

Recommend Reason

- Operation Cost is very low.

- Flexibility in processes.

- Energy consumed is very low.

- Easy to handle.

- Controlling needs complete accuracy.

- The cooling section is incorporated within system.

9.ROMACO

Company Background & Information

Romaco Group is one of the most renowned groups in producing processing and packaging solutions and supplying them to the whole world with an experience of over 50 years.

They have been providing a solution to the pharmaceutical and food industry with a wide range of machinery with advanced technology incorporated in it. Their tube filling, granulation machines, and fluid bed dryers, etc. are very famous in the whole global market.

Products of Romaco are almost available in all pharmaceutical industries and this is where they will be sharing 27% of the market share for exporting products to the global market.

Key Products

- Pharmaceutical Fluid Bed Dryer.

- Pilot Fluid Bed Processor.

Recommend Reason

- Machines with high precision.

- Easy to handle.

- Working principle easy to understand.

- Less space occupying machines.

10. Glatt

Company background & Information

Glatt was established in 1954 as a small business producing stoves pipes. Slowly and gradually Glatt expanded its business and associated with strong partners such as pharmaceuticals, food, chemicals., etc, and formed its own chains from designing to constructing customized machines. The prime motive of Glatt is to form an efficient, innovative, excellent ideology in producing industrial types of machinery.

Their developed bespoke pharmaceutical machinery is popular for their cutting-edge technologies. They offer you granulating machines, coating, and huge series of drying equipment. In pharmaceuticals, for over 60 years they are most preferred firm for providing equipment used in drug development, formulating, filling, and clinical management.

Key Products

Some diverse range of fluid bed dryers include:

- Mini-Glatt

- GPCG 10

- Fluid bed dryer WST

Recommend Reason

- Glatt offers you a gentle and fastest drying process.

- Flexible and hygienic design.

- Easy processing and cleaning.

- Exhaust air is filtered prior to release in a natural environment.

- Solvent recovery delivers economic benefit.

- CIP and WIP systems

Conclusion

Fluid bed dryers play a fundamental job in the pharmaceutical manufacturing area. Fluid bed dryer guarantees fast and homogenous drying which is ideal for heat-sensitive ingredients. AIPAK Pharmaceutical Machinery comes in a wide range of fluid beds, easy to use and less labor-intensive. You can opt for them for continuous production or batch-material production.

Don't forget to share this post!

Drier Machine Related Products

Drier Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours