Your Premier Induction Sealing Machine Supplier

- High Sealing Efficiency

- 100% Firmly Sealed

- Wide Application Range

- Stable Performance

AIPAK Induction Sealing Machine

AIPAK Induction sealing machine uses the electromagnetic inductive theory and adopts the transistor modular design. When a bottle is passed through a magnetic field with high frequency, aluminum foil over the mouth of the bottle will produce high heat instantly under the effect of high frequency. The high heat will be transmitted to thermal film in a very short time, so the thermal film is fixed to the mouth of the bottle firmly and seals the bottle. This sealing machine can be widely used in industries that require sealing such as medicine, food, cosmetics, pesticide and chemical products to prevent moisture, mold and theft. Bottles that can be used include non-metal bottles made of PE, PP, PET, PS, ABS and glass etc. The machine will not touch the mouth of the bottle during its operation, and the bottle will be 100% sealed firmly, which meet with GMP standards.

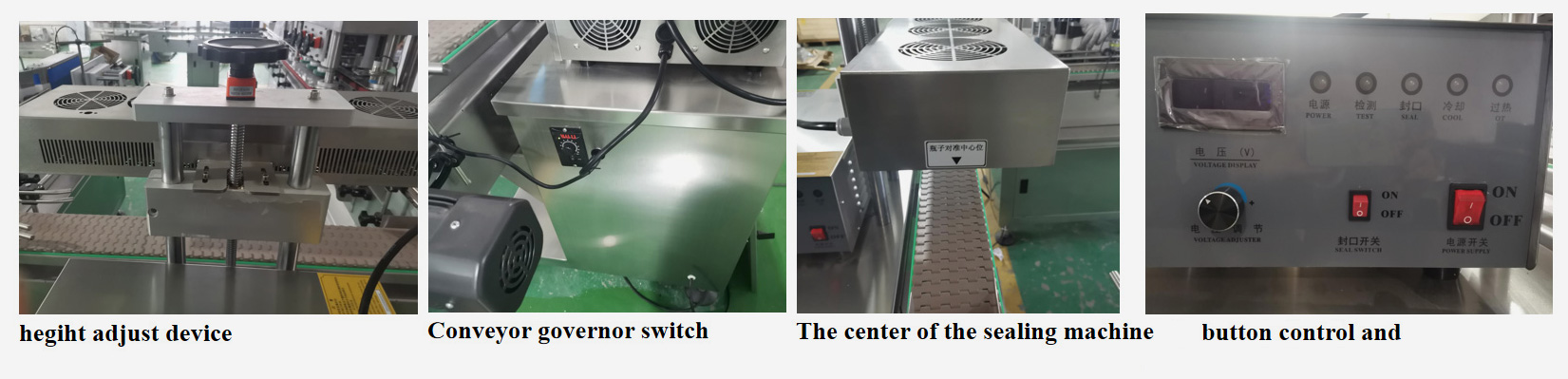

Main Structure Of Induction Sealing Machine

The Buyer's Guide

Induction Sealing Machine: The Complete Buying Guide In 2025

Induction sealing machine is used to seal bottles with aluminum foil increasing content stability providing protection from environmental factors and adulterations. What is a better way to start the New Year then buying a top notch induction sealer for your production line? Bringing you INDUCTION SEALING MACHINE: THE COMPLETE BUYING GUIDE IN 2023. All you need to know before buying this equipment is discussed in this article.

1.What is induction sealing?

Induction sealing in brief words is a process in which through heating thermoplastic materials are bonded together. This involves non-contact heating and welding of aluminum foil to mouth of bottles or jars. This creates an airtight sealing to protect the integrity of contents inside the containers. Induction sealing also referred to as cap sealing, is commonly used to seal plastic and glass containers like jars, bottles, tubes, etc of various sizes.

2.How does induction seal work?

The induction seal is specialized foil made up of three layers i.e. backing, foil and heat seal. The layer closest to the mouth of the container is heat seal followed by foil and finally backing which provides structural integrity of the seal. First bottles or jars are filled with products. Then this filled container and cap goes through induction sealing machine, where electromagnetic coil generate heat energy.

This heat energy is transferred to aluminum foil that melts the sealant foil or wax. The pressure for melting is provided by threaded cap. Inductive coil create current that heats the inner foil seal. Outer polymer melts and get bonded with container.

Hermetic seal is formed on the top of container when temperature of container lowers. Sealant stick to container once it cools.

3.What are the advantages of using induction seal?

Induction sealing is very advantageous and cost effective method to maintain the integrity of the product content packed in various containers. Some pros of induction seal are given below:

Good Hygiene

Induction seal helps to maintain the hygiene of the product. By induction seals, contents of containers are safe from contamination and no pollutant or contaminant can enter the container.

Tamper Proof

FDA has stringent rules concerning tampering of the pharmaceutical products. Induction seal provides anti-tampering seals that meet the regulatory norms. Products sealed in containers are removed without breaking or tearing the seal.

Leakage prevention

Induction sealing does not allow the leaking of the inner content. This helps in preventing the messy and costly spillage of the chemicals that cause hazardous accidents.

Longer Shelf Life

Induction seal facilitates in maintaining the freshness and durability of the product. Induction seal assists in conserving the quality of the product, thereby lengthen the lead-time of the product.

Customer Satisfaction

By induction sealing, the product credibility is maintained and quality is ensured. This aids in assurance of customer and gaining their trust on product integrity.

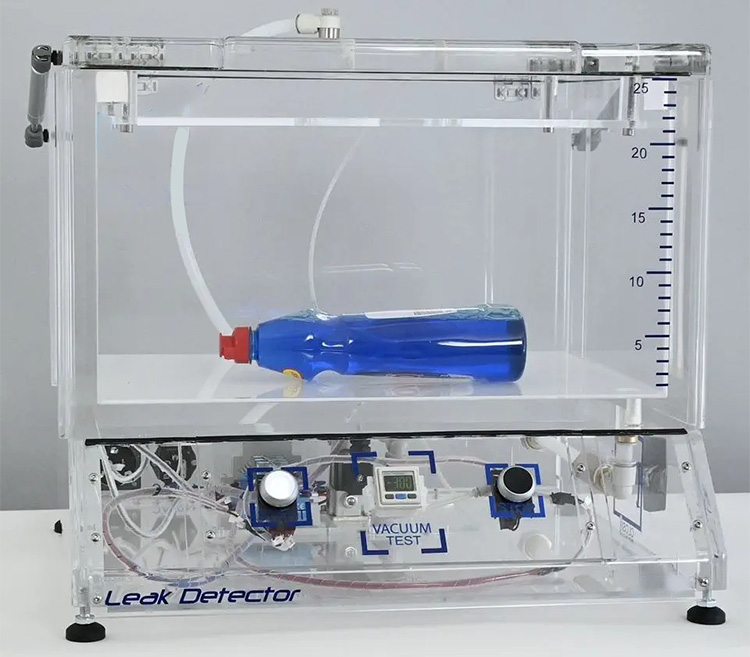

4.How to check the integrity of induction seal?

A good seal means better preserved content without any tampering or adulteration. There are different methods, from simple to sophisticated ones that you can try to check the integrity of an induction seal. One of the simplest one is to remove the cap of container, turn it sideways or upside down and squeeze. No leaks mean the seal is perfect.

One sophisticated method involves the use of water bath vacuum chamber. The container with the seal is placed in the chamber where leaks in the seal are detected by observing escaped air bubbles.

Vacuum bell jar chamber method is similar to water bath vacuum chamber method where the container is placed inside the bell jar. The pressure inside is gradually decreased creating vacuum followed by popping of the seal. The pressure at which the seal is opened is indicative of the nature of seal.

5.What are the industrial applications of induction sealing machine?

Packaging is important in several industry and induction seal machines have significant role in packaging of different products. Induction sealing machines maintain durability and freshness of many products. Some major industries in which induction sealing machines are essential are given below:

Pharmaceutical Industry

Packaging of medicines must be tampered resistant as require by the regulations set by drug authorities. In this aspect, induction sealing machines play an important role. These machines seal the bottles of tablets and capsules so that contents of bottle are not extracted without breaking seal.

Food Industry

Freshness and hygiene of food stuff such as pastes and sauce are two main aspects when buying these products. Induction sealing machines assist in preventing contamination of food by microorganisms and retaining crispness of food.

Chemical Industry

Chemical bottles and jars are sealed by induction sealing machine like lubricants, glues, paints, polishes, petroleum products in order to avoid leakage of these harmful chemicals that cause injuries and combustion.

Cosmetic Industry

In cosmetic industry, induction sealing machines are used to seal the containers of creams, foundations, powders, etc to increase their shelf time.

Dairy Industry

Dairy products like milk, cheese, butter, yogurt, and creams are packaged by induction sealing machines in air tight containers so that these products do not get spoiled by bacteria and fungus.

Personal Hygiene Industry

Personal hygiene products like tube paste and various cleaners are sealed in tubes and jars by induction sealing machines to maintain their quality.

6.How many types of induction sealing machines are available in the market?

All depends on your need! As a small business owner or a manufacturing industry different types of induction sealing machines such as hand held sealer, a semi-automatic or a fully automatic induction sealing machine are available to cater your requirements. The only difference between each machine is automation or number of units that you can seal in given time.

Hand held induction sealer

An excellent back up tool for small scale businesses or research labs that provide accurate and efficient seals. Equipped with fail safe features to avoid over heating this device is easy to use and operated by a single button present on the sealer.

Hand held sealer- Picture Courtesy

Semi-automatic induction sealing machine

Semi-automatic induction sealing machine is a superior version of hand sealer used in research and development and small to medium scale production. A sturdy built due to stainless steel main body increases the working life years of the machine.

Semi-automatic foil sealing machine- Picture Courtesy

The degree of automation is different in semi-automatic and fully automatic machine. Based on size and shape of the bottle you can seal about 20-220 bottles in a minute.

Automatic induction sealing machine

Automatic induction sealing machine can fill product, seal bottles and stack them in the container. If you opt for this machine you do not need to buy separate individual units to perform other functions. You can also attach automatic machine to other different units of production line a conduct smooth, error free operations with a press of a button.

Fully automatic induction sealing machine

7.How does an induction sealing machine work?

These machines seal the containers in two ways.

- Cap Sealing

- Cap less Sealing (Direct Sealing)

Cap Sealing

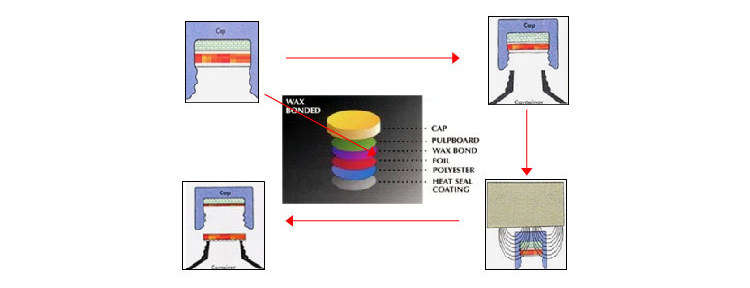

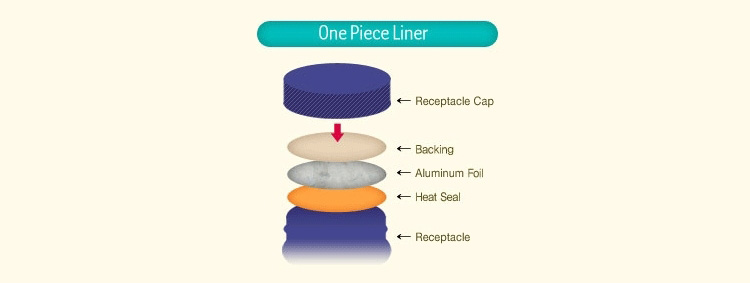

Induction sealing machines perform cap sealing using aluminum foil liner. These foil liners come in one piece and two piece.

One piece liner

One piece assembly includes foil laminate such as foam-based or paper backed. Inner seal remain bonded to container when sealing process is completed.

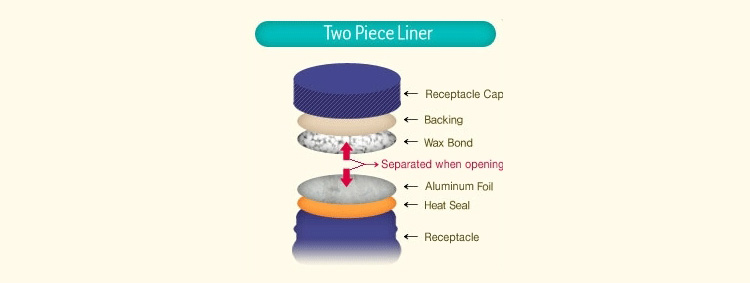

Two piece liner

This assembly has wax and pulp board layer in addition to foil laminate that is also present in one piece assembly. It is most widely used in induction sealing as pulp board aid in resealing.

Mechanism

When container goes underneath inductive coil, these emit robust electric current, which melts the liner. The wax of two piece assembly liquefies, taken up by pulp board and is then foil is freed from cap.

Outer polymer heats up and sticks to opening of container. Cooling system decrease the temperature of this layer so airtight sealing is formed.

Cap-less Induction Sealing

It is direct method of sealing container without using caps. It uses pre-cut foil or foil reel. If foil reel is used, then machine will cut it and fix it to opening of container.

The sealing head starts the process of induction sealing; afterwards foil is placed at the top of container, this process heats and glues the foil to container.

8.Major components of an induction sealing machine.

Induction sealing machines have different parts depending upon the kind of induction sealing machine. But some parts are common in all the type of induction sealing machines. Some major parts are discussed below:

Sealing Head

Sealing head is the main part that is required for the working of induction sealing machine. It contains inductive coil that heats the foil. Sealing coil is good conductor made of iron and covered with plastic that act as insulator.

This inductive or sealing coil emits electromagnetic eddy current. There are many ferrites in the sealing coil that give it larger surface area to blast the current.

There are two types of inductive coils.

Flat Sealing Head

This type of sealing head scatters electric current in all direction to provide large surface area. This sealing head is excellent for sealing flat caps having diameter of 20 millimeter to 120 millimeter.

Tunnel Sealing Head

Tunnel sealing head directs current around the side thus creating a uniform electromagnetic field and reliable seal. This sealing head is used for push through caps, York caps etc.

Power Supply

The power supply consisting of cable and socket provides the energy for working of the machine. The power needed for operation of machine depend upon type of sealer and speed of manufacturing.

Conveyors

These components transmit containers to sealing head.

Control Panel

Control panel is an interactive touch screen display on which various parameters like temperature, count of seal bottles, etc for running the machine are program.

Cooling System

Cooling systems consist of cold compressed air or water compartments. Water cooling systems have pumps, hoses, infiltrators, and circulators. But air cooling systems are efficient and commonly used in packaging industries.

These help in adhering of polymer film to opening of bottle and creating hermetic seal.

9.How to trouble shoot an automatic induction sealing machine?

Problems and errors arise during every operation even in induction sealing machine. But you can easily solve these errors by following some suggestions given below.

Insufficient Sealing Current

Sometimes sealing head does not enough power for emitting electromagnetic current.

Cause

- It can be due to placement of metal guard rails near the sealing head.

Remedy

- Replace the metal guard rails underneath the sealing head.

Burnt Seal

Sometime you see the paper board of seal has burn mark on its surface.

Cause

- Speed of conveyors is low

- Excess voltage

Remedy

- Properly adjust the speed of conveyor

- Regulate the voltage

Containers are not Sealed

Sealing head is not sealing the bottles even when machine has proper voltage

Cause

- Heating time of inductive coil is low

- There is damage to inductive coil

- Sealing containers and film materials does not match

Remedy

- Increase the heating period of inductive coil

- Replace damaged inductive coil with new one

- Select sealing film that is matched with sealing object

Sealing Film is Melting

Sometimes you see sealing film gets fold and dissolve

Cause

- There is extended period of heating coil.

Remedy

- Reduce the heating period of coil

Tight Caps

The caps are tightly closed after sealing and cannot be easily removed.

Cause

- Insufficient power

- High coil set

Remedy

- Check the power input

- Modify the height of coil

10.Installation, safety, precautions and occupational hazards associated with induction sealing machine.

Occupational hazards while running induction sealing machines can cause accidents, injuries, and money loss. Safety precautions should be taken into accounts to avoid such incidents. Some safety precautions are written below for your information.

- Switch off the machine before working on power cable. First cover the machine then switch on the machine.

- If you are working on power enclosure do not stand on grounded surface or water.

- Do not run the machine near flammable vapors, combustible material including dust as high voltage of machine can cause explosion.

- You should not seal the containers with faculty sealing head as it can ignite.

- Always wear protective equipments like overall, gloves, closed foot wear while maintaining the induction sealing machine.

- Do not seal metal containers with induction sealing machine unless mentioned in the manual.

- Machine should not be allowed to get damp during transportation, storage, and operation.

- Use light guard to prevent close contact with the heated inductive coil.

11.Maintenance and cleaning of induction sealing machine.

Maintenance and cleaning are crucial for healthy and long operational life of induction sealing machine. Some tips are given below for maintaining the efficient performance of your machine.

Daily Maintenance

- Regularly clean the front panel and exterior of the machine using moist cloth.

- Check cables and connectors for damage regularly.

- Inspect sealing head for any discoloration, cracking or burns daily before running. Closure of sealing head must be intact, free of kinks and should not be overheated.

- Examine for voltage fluctuations.

Weekly Maintenance

- Weekly inspect machine for detecting any issues with the machine.

- Clean the filter of sealing head and fan present at the back of power supply to remove dust particles and corrosives using compressed air.

- Change the oil in the gearbox weekly.

- Lubricate screws, sealing coil, and cart wheels.

Monthly Maintenance

- Check the working conditions of safety switches

- Examine whether there is leakage in the cooling system.

12.Conclusion

Induction sealing machines play an essential role in manufacturing tamper resistant packaging. These are integral in preserving quality of good. Hopefully you have learnt about various aspects of induction sealing machines such as its working, type, application, troubleshooting, and maintenance by reading through this guide.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586