Paintball Machine: The Ultimate Buying Guide In 2025

Paintball is an exciting competitive shooting game in which players eliminate one another by hitting them with paint filled soft gelatin balls, loaded in a pressurized gun.

Each team gets different colored balls and these balls explode on contact with players. When players are marked they are removed from an ongoing match. The team with most numbers of players in the end wins the match.

Well if you are wondering how these balls are made or if you want to invest your money in the best available equipment in the market; you have come to the right place.

Bringing you “Paintball Machine:the Complete Buying Guide in 2022”. At the end of the guide you will be able to identify your needs, prepared to select the best available machine and ready for operations. Before investing your money, grab a cup of hot coffee and enjoy this blog!

LET’S Go!

1.What is paintball (s)?

Paintballs are gelatin balls filled with different colored liquid, intended to be shot using air gun. They are almost similar to a large vitamin E capsule or oil beads.

Paintball manufacturers offer many bright colors balls such as blue, yellow, red, orange etc. These are used in an outdoor game played on different terrains.

In paintball game, paintballs are shot strategically between two teams. When a paintball hits a player, thin textured gelatin ball ruptures and liquid inside leave a bright mark of paint and marked players are excluded from team or game.

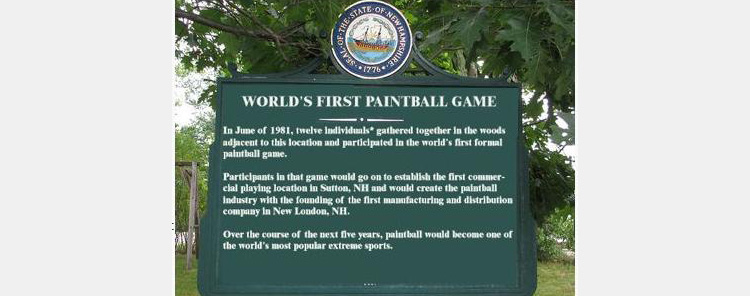

2.When paintball game was introduced?

Paintball game is relatively a modern game. The game originated in 1960 when Charles Nelson from renowned ‘Nelson Paint’ invented innovative paintball markers that would later become the paintball guns, for marking livestock and trees.

In 1981 first official game was seen that captured the interest of people. Furthermore, Gaines and Gurney Noel, friends of Charles Nelson saw a business opportunity and began to selling game kits such as paintballs, goggles, markers as well as rulebook. In 1983, Gurney organized the first ‘Survival Game National Championship’ paintball tournament which was won by Canadian team.

Today, paintball is multibillion pound sector with broader range of guns, mask, indoor and outdoor games with unlimited gaming formats.

Now people enjoy paintball game as an interesting and famous entertainment with rich history. As more people show interest in playing this game more paintball industry grows with tremendous profit.

3.Paintball equipment and paintball guns (paintball markers); a brief overview.

After paintball game was officially introduced in 1980s, this game became phenomenally popularized worldwide in short time. The main feature of paintball that makes it apart from other sports like basketball or volleyball is the equipment involved.

Because you don’t find equipment like guns or projectile paintballs in various traditional games let’s find equipment and their uses.

1.Paintballs

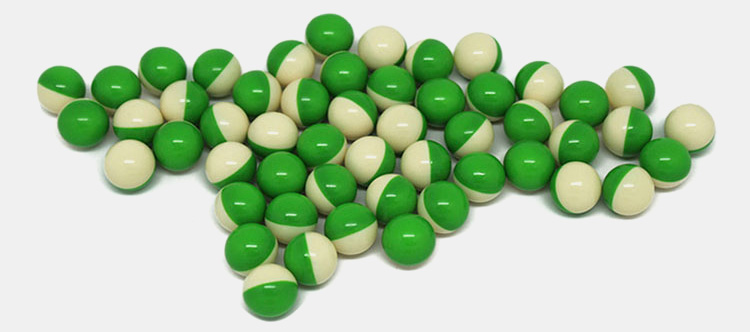

Paintballs

The basic thing involved in paintball game is paintballs itself! Just like basketball, tennis or football, paintball or rather paintballs are central element of the game.

At one time you may have dozens and hundreds of balls to play. Paintball is constructed by using soft gelatin. It contains colored liquid wrapped in a gelatin capsule. You will find paint in various colors, which are non-toxic and biodragable. So you can easily wash off your skin and cloths.

2.Paintball Gun or Marker

The paintball gun also known as a paintball marker fires balls at a very high rate. Gun itself has compressed gas propulsion system, which compresses carbondioxide, nitrogen or ordinary gas. It is stoored in small cartridges or a larger tank which is intregtraed with gun. Not only this! gun is also attached with a hopper that feeds the gun with paintballs.

For safety the markers are adjusted with ‘top speed’ of fire of 300feet/second. So, you can enjoy the game without worrying for being injured. But it is recommended to wear helmet while playing since newer equipments can fire at more speed.

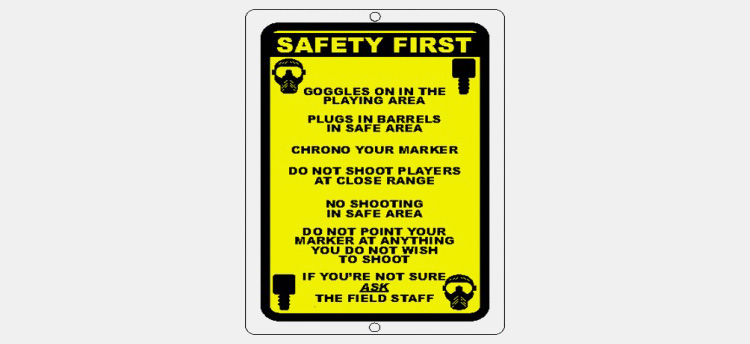

3.Safety Equipment

With development of paintball game, safety equipment were introduced. So, when paintball hits your body, it will feel like a brief sting. But it may knock eye out if it hits your eye. So be careful!

Battle Packs

Battle packs should be put on around your waist which is composed of four pods, each of them is capable of carrying 100 paintballs. So, a full pack can carry up to 400 paintballs in battlefield.

Safety Goggles

As a paintball warrior you will need to wear safety goggles. For this purpose many player uses eye-protectors. In older days players wore no eye-protectors, but now many players use safety protection, in fact it is absolutly mandatory.

Such customized paintball goggles are designed in order to fit perfectly into helmet, hence offering a complete 360O protection. These goggles are filled up with vents that keep continuous flow of air and protect steaming.

Combat Suit

Your combat suit is the one of the most stylish gear you use while playing game. This suit is available in all sizes to cover your arms, legs etc. Collar protection is an added bonus to cover your neck while playing game. If used correctly it will protect you and your cloths from paint.

4.Where to buy paintball equipment?

AIPAK paintball equipment

Paintball game is a highly competitive and extreme sport. Although the markers or paintball guns are low energy weapons, they can seriously hurt if proper gears are not worn.

Paintball equipment and related accessories are available online and from various shops around the world. For your own safety do not compromise on the quality of safety gears that include safety helmet, safety goggles and combat suit.

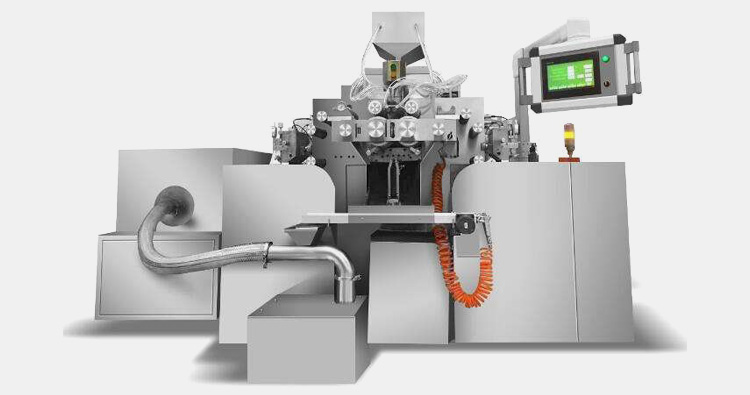

5.Paintball machines are actually softgel encapsulation machines!

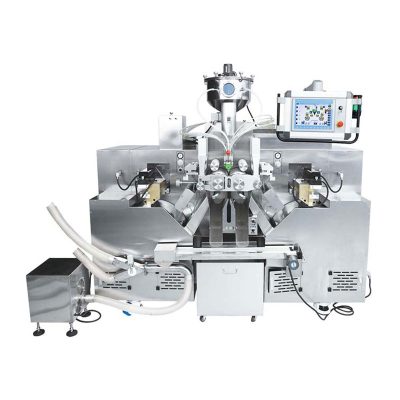

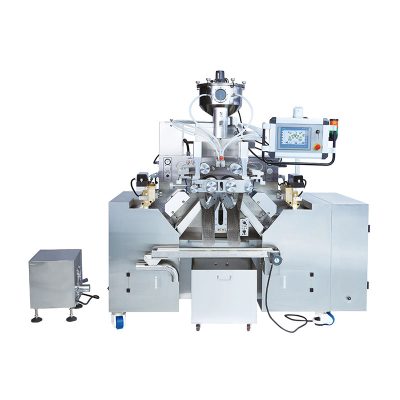

AIPAK softgel encapsulation machine

It was after the emergence of paintball game with increased popularity and evolution, paintball manufacturers appeared on the canvas of industrial manufacturing. In the beginning however, paintballs were primarily manufactured at pharmaceutical companies as they already had desired equipment and machines.

Paintballs

You will be surprised to know that the machine employed in the manufacturing of vitamin E softgel capsules can also be used to make paintballs and is commonly known as softgel encapsulation machine.

6.What is an automatic paintball machine or softgel encapsulation machine?

An automatic paintball machine or softgel encapsulating machine is equipped with a PLC controller, a user friendly interface that controls operations from start to end with minimal operators’ input.

All the parameters are entered at the beginning of the operations and the machine performs accordingly. Automatic paintball machine can cater your needs whether be small scale or large commercial scale production with precision and accuracy.

AIPAK Fully automatic paintball machine

When buying this machine you should not be concerned with working efficiency since automatic paintball machine is equipped with fail safe features that detect any anomaly in the production line and removes them.

This entire blog is about automatic paintball or softgel encapsulation machine; continue reading to know more about working and construction of an automatic paintball machine.

7.An outline of paintball making machine technical specifications.

When you are looking for equipment, the biggest factor is how much money you are going to invest. A smart move at your end would be to buy the machine that’s optimal in cost and caters 100% of your requirements.

Keep in mind that buying substandard machine will cost you in the long run. You should look for these before selecting any paintball machine or softgel encapsulation machine.

You will find different machine with different technical specifications in the market. Standard unit can be operated at a power supply of 120 V or 240 V. Below are the available parameter that you will need to understand your requirements.

Balls in an hour: Standard softgel encapsulation machine is capable of producing 20K paintballs in an hour at nominal speed. At maximum speed the output can be increased to 100K paintballs in an hour.

Size of die roll: You can customize die roll according to your requirements. Standard version of softgel machines are provided with die roll in a range of 80x100mm – 150x250.

Weight of machine: Since paintball machine or softgel machine can be customized. Depending on what features you select the weight of machine is changed. An automatic paintball machine will typically weigh around 600-1000 kg. Inclusion of dryer and other units will increase the weight of the machine up to 1600kg.

Power generation: Standard softgel machine is powered by a 1.5KW three phase motor. If you have requested for a customized softgel encapsulating machine the power generation can be increased upto 16KW.

Filling accuracy: The softgel encapsulating machine is equipped with a PLC control panel that drastically increases its filling accuracy. Filling accuracy of standard model lies between 1.5-2.0%.

8.An insight on the construction of paintball machine.

The major components of paintball machine are as follows:

Hopper

Hopper of paintball machine holds the filling material that is intended to fill in balls. The filling material include bean oil, starch powder, polysorbate and wide range of coloring agents etc.

Both shell of the balls such as gelatin and filling material should in a melted form and kept at a constant temperature. The construction of machine hopper is facilitated with hot water jacket that seamlessly provides heat to the content. Furthermore, a circulating jacket indicates a liquid level.

Paintball Machine

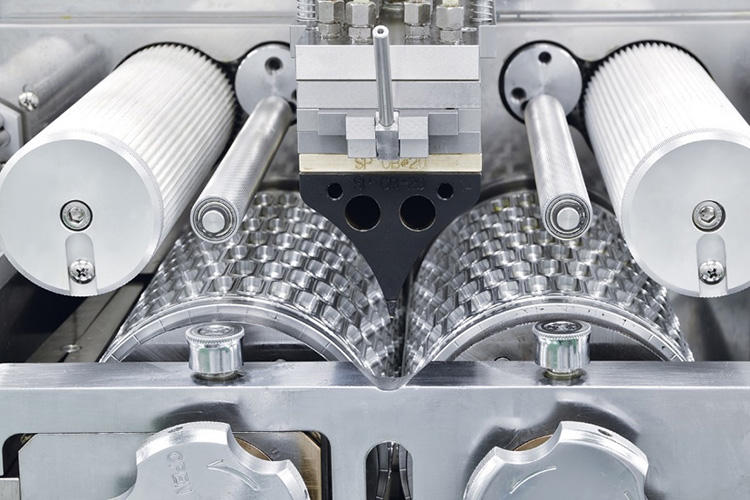

Die roll shaft

Die Roll Shaft- Paintball Machine

Two die rolls are mounted on die roll shaft left and right respectively.

Die-roll

Die-roll of paintball machine enables molding of paintball into respective shapes and sizes. This component of paintball machine is of prime importance as entire shape and encapsulation process relies on it.

Strips from hopper enters die roll for encapsulation of paint and formation of paintball. Die roll ensure the production of high-quality paintball without worrying about deformation.

Die- Roll- Paintball Machine

Die roll alignment assembly

A die roll alignment assembly is present at the back side of die roll housing assembly.

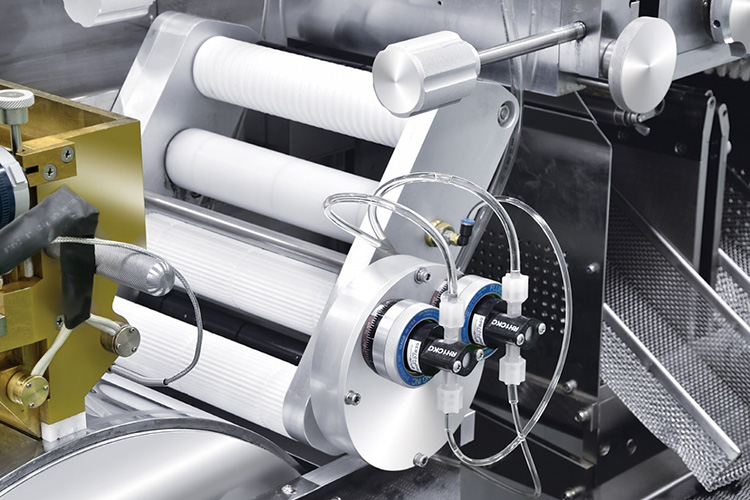

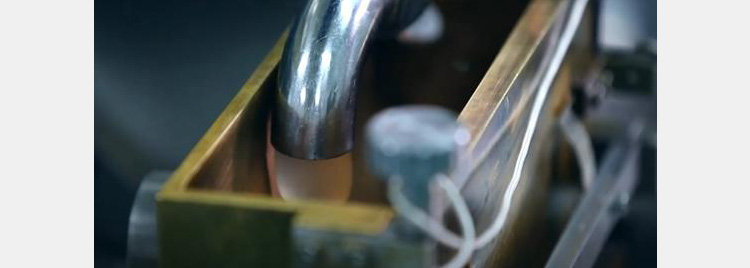

Ribbon lubrication and drive unit

An oil roll system is located at both side of die roll that allows fine lubrication of liquid paraffin to lubrication pump that enable ribbon lubrication. This is made up of porous material.

You can easily feed the unit by two oil formulations.

Ribbon Lubricant Unit- Paintball Machine

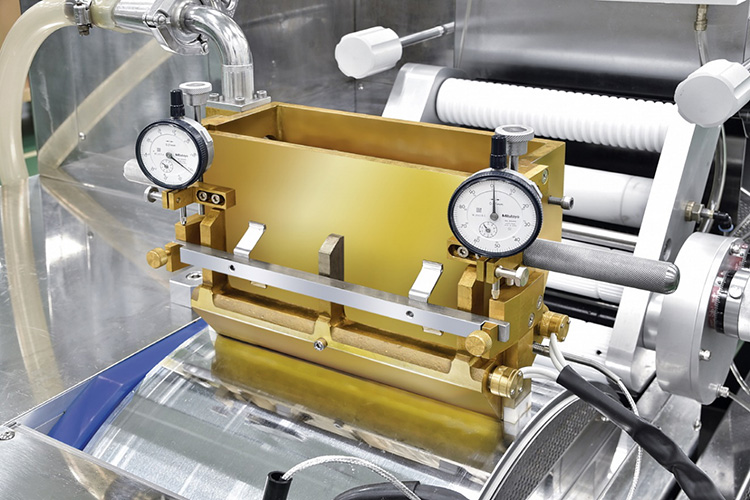

Spreader box

Standard version of paintball machine is equipped with a spreader box that can store gelatin liquid in molten state soon after receiving it from mixing tank. A spreader box saves wastage of gelatin and saves up to 10%. The size of spreader box depends upon pocket number of die roll.

Bronze Spreader Box- Paintball Machine

Electric cabinet

Electric Box

An electric box is made up of stainless steel that assembles all mandatory electric parts such as several terminals, breakers, etc. You will require a trained technician to operate and maintain the electric cabinet.

Plc control touch screen

If your softgel does not include PLC control panel than you need to upgrade your machine.

A paintball machine has customizable PLC control touch screen. This screen allows the user to view and control every step of the process such as production speed, output speed and view. Also, it allows the user to manage the electrical, machine die roll, liquid pump, casting drum etc.

A PLC- Control Touch Screen System-Paintball Machine

9.Working of paintball machine.

The paintball machine works in a very simple way which becomes easier with advanced electronics and control system.The processing of paintball include:

1.Melting

This process occurs in two steps such as preparation of paint and then transferring it to encapsulation plant. On a large scale, manufacturers prefer to combine these procedures.

Above- Paint mixing. Below- Paint and Gelatin incorporation

This process is accompanied by using gelatin, glycerin, and purified water. These ingredients are melted in melting tank under 120 degrees Celsius.

Paint used for preparing paintball is basically water-soluble and it can easily wash out. Making of paint is very important process for paintball manufacturing. The reason for this is optimization of paintball manufacturing to form a water soluble and bio-degradable product for encapsulation.

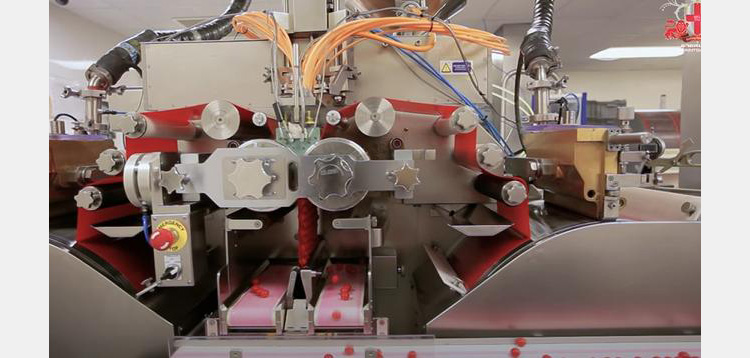

2.Encapsulation

Paintball machine facilitates the encapsulation of paint in an efficient way.

Gelatin loaded onto encapsulator- Paintball machine

On a larger scale, the making of paintball takes place in a continuous process using encapsulation machines actively for 24hrs/7days a week. The encapsulation process requires several workers with specialized clothing and appropriate PPEs working in a clean environment.

To make a ball;

- Load two gelatin strips onto encapsulating equipment.

- These strips are allowed to move via two counter rotating drums.

- These drums help to line with pockets to form a paintball casing.

Gelatin ball casing filled with paint

- As gelatin is pushed/pressed into pocket it automatically injects an optimized amount of paint into the casing of balls.

- Furthermore, it will also automatically seal the strips to form an encapsulated paint.

Paintball Formation

Paintball Manufacturing Process- Video Courtesy- Camfouflage Paintball

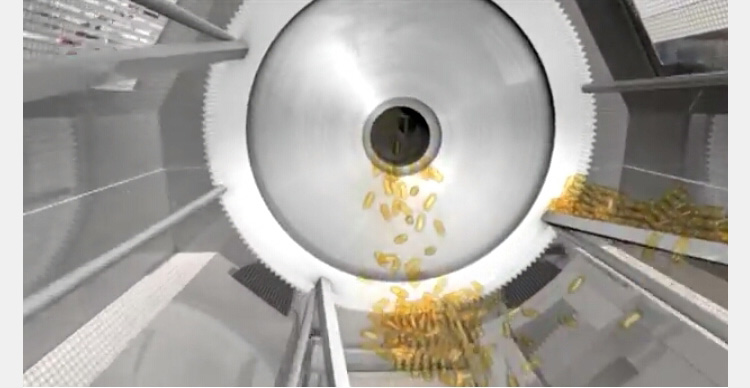

3.Tumbling and drying

At this point, gelatin is soft and warm. Therefore, cooling and hardening of paintballs takes place in a tumbling machine that gently shakes the balls around. The rotation of tumbler spins the balls and helps in uniformly drying.

Tumbling of Paintballs

The paintballs are then transferred on the shelves which are stacked with wheeled racks and allow the paintballs to air dry. The air-drying time varies at each manufacturing industry depending up on concentration of gelatin and tumbler time.

Drying Process of Paintballs

There are certain important steps that are performed to assess quality of manufactured paintballs, such as:

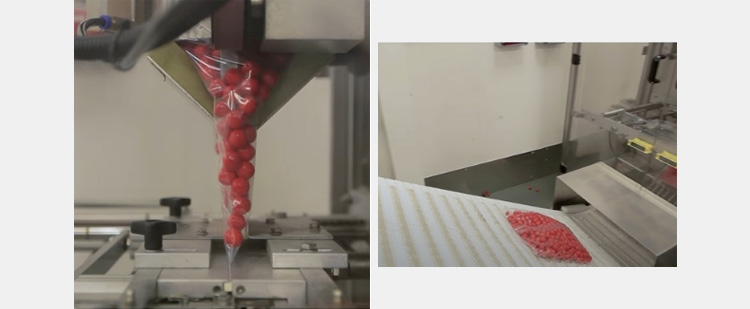

Inspection and packaging

Weight and Visual Inspection of Paintball

Balls are ready to pack soon after achieving optimum drying. Paintballs are visually inspected to detect obvious flaw. The rigorous quality assessment is done for batch to batch consistency.

Loading and Packing of Paintballs

These balls are loaded into the hopper of packaging machine that automatically grabs the balls and seals them into packaging bags. The packaging is performed followed by weighing of balls because machine makes balls casing by weight. Each case of balls holds approximately 2,490-2,510 numbers.

Quality control

On a larger scale manufacturing facility, paintball manufacturing is a continuous process divided into various lots. This allows manufacturer to obtain same quality without batch to batch variations.

Paintballs

Using statistical parameters such as percentage, accuracy and precision along with visually checking weight and diameter in each batch ensures a quality product. Furthermore, a drop test is performed to know the brittleness of paintballs. So, quality control is an important step to obtain target range.

By-products/waste

Paint balls are environment friendly products because they are specifically manufactured as biodegradables. Both paint and gelatin can easily dissolve in water thereby leaving no residues.

10.Classification of paintball machine into different types; based on use.

The classification of paintball machine is categorized into three main types:

Small scale paintball machine

A small-scale paintball machine is used to make paintballs on a smaller scale. This machine is compact and requires less space for installation. A small-scale paintball machine is an automatic machine that yields a robust outcome.

You can set all the parameters using PLC touch screen. You can also integrate this machine with tumbler dryer to attain excellent production.

Small Scale Paintball Machine

Medium scale paintball machine

A medium scale paintball machine is mainly used in pharmaceutical, health and food sector to encapsulate medicine or vitamins. This machine requires larger space than a smaller version. You can also integrate supportive components like cooling drum, dryer etc. to it.

Medium Scale Paintball Machine

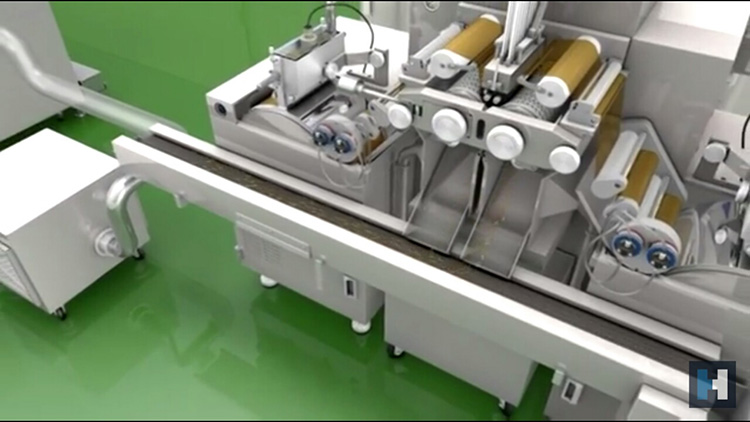

Large scale paintball machine

A large scale paintball machine is a perfect machine to run large quantity paintballs batches. This machine is highly employed in pharmaceuticals, nutraceuticals and food industries also to obtain large scale production.

This paintball machine extensively requires integration of essential units such as spread box, conveyors unit, rotary die roll etc. It typically forms a production line made up of individual units.

A Large Scale Paintball production line

11.How to operate paintball machine?

Paintball machine is very easy to operate and with proper training anyone can operate it without much effort. To operate paintball machine, you will need to follow below mentioned steps:

STEP #1

- Wear proper gown, goggles, mask, gloves and shoe cover before beginning the operation.

- As mentioned earlier whole procedure is based on three steps.

- Accurately weigh the ingredients. Open the melting tank and add all ingredients and close the tank.

- Start the mixer to completely mix the ingredients.

- Switch on the heating device and set the jacket temperature at 120⁰C. Normally gel mass and other ingredients take 30 minutes to melt and mix completely.

- Switch on the holding device and pre-heat it at 85⁰C.

- When ingredients in mixing tank melt completely. Stop the mixing and remove the bubbles using vacuum pump.

- Now connect the discharge tube of mixing tank with pre-heated holding tank to transfer the melted mass.

STEP #2

- Transfer the holding tank toward encapsulation unit and connect it with encapsulator (spreader box) with help of connecting pipe.

- Switch ON the encapsulator and SET UP the setting for encapsulation process on PLC touch screen.

- Connect the holding tank with compressed air pipe to press the gelatin mass from tank to spreader box of encapsulator.

- Set up the wedge and start encapsulation process.

- Once encapsulation process becomes stable, production of paintballs become rapid according to feeding data.

STEP #3

- Switch ON the integrated tumble dryer.

- Put the paintballs into tumbler dryer for removing unwanted sticky ingredients.

- Then move them into the drying area.

- Control the relative humidity of drying area up to 20- 30% under 24⁰C for 24 hours.

12.Can the paintball machine be attached to a production line?

Paintball machine can be attached to different auxiliary equipment to transform it into a significant production line. For instance:

Gelatin mixing tank

This is used to melt gelatin and other ingredients such as starch, glycerin, water and oil.

Connecting pipes

These are integrated with paintball machine and gelatin mixing tank in order to connect with spreader box of paintball machine.

Connecting Pipes

Vacuum pump

A vacuum pump is used to remove bubbles from gel in pre-heated holding tank before transferring to encapsulation machine.

Vacuum Pump- Paintball Making

Cooling drum

Cooling drums helps to cool the hot gelatin in order to form a ribbon of gelatin.

Conveyor belt

After formation the paintballs are directly discharged over conveyor belt that moves them into tumbler dryer.

A fan blower/tumbler dryer

A spinning action of tumbler dryers helps in drying of paintballs. Upon continuous rotation paintballs get dry and then transferred to basket ejector.

Tumbler Dryer

13.How to perform maintenance of paintball machine?

By now you should be enlightened on how necessary it is to perform maintenance at a scheduled time. Taking care of your machine will increase its working life. Following points should be thorough read and understood to ensure proper maintenance without any damage to machine or personnel.

- Maintenance of paintball machine should be carried out by experienced staff. These personnel are usually from engineering department.

- Make sure that your men never by-pass any safety protocols while performing the maintenance.

- Personal protective equipment should be worn at all times during maintenance as well as daily operations. These include safety shoes, safety goggles and helmet.

- Maintenance is usually conducted regularly based on utilization of the equipment.

- The electrical earthing of the equipment should be checked on regular basis (refer to manual).

- Moving parts should be greased and oiled after a week.

14.What are safety, installation and storage requirements of a paintball machine?

When you buy a paintball machine you will get a working manual with it. Follow the guidelines mentioned in the manual thoroughly to avoid accidents and malfunctioning of machine. For your knowledge some of the guidelines are mentioned below.

General Safety Requirements

- Automatic paintball machine comes with built-in safety features however, caution is advised when operating the machine since not all accidents be avoided through built-in safety features. Therefore, the installation be carried out by experienced personnel so as to avoid any damage.

- Trained individuals should operate the machine. You should never by-pass any safety system when machine is switched ON. Caution is advisable when working around your machine during operations. Take special care with the moving parts.

- You should never place tools or other stuff on the main body while working on the machine or doing maintenance.

- According to working SOP of the machine never operate the machine under the influence of alcohol or sleep inducing medicines.

- Automatic paintball machine is equipped with emergency STOP button. Press the button only in case of emergency situations. Avoid using emergency STOP for regular stops as it reduces the machine’s life.

- Use of sign boards should be part of your working SOP.

- When machine is not under use or under maintenance cut off the main power supply, even when the machine is switched off there is a flow of current in electrical components.

- Report any unusual noise or smoke or excessive heat.

Installation requirements

- Use of fork lift is recommended to move the machine from the container to installation site. You can also use a hoist with a capacity of 2000Kg. Special care should be taken when moving the machine to avoid any accidents.

- Paintball machine is quite heavy. You will need a levelled floor strengthened with concrete. You can also use steel platforms.

- Where the machine is installed the clearance from all sides should be approximately 6 feet. This will facilitate the operations and maintenance, also machine should be in clear view during operations.

- The paintball machine is provided in wooden crates. Use hammer to remove the top wooden crates before moving to the sides.

- When you first receive the machine inspect thoroughly each parts and report the damage if any incurred during transportation immediately to the manufacturer.

Storage Requirements

You can be rest assured that the product you have received has passed regulatory and quality requirement at the manufacturing facility. The manufacturer recommends the installation upon arrival, if for any reason the machine could not be installed immediately following points should be considered.

- The paint ball machine should be store in a dust, water and direct sunlight free environment

- The machine should be stored in place where there is minimum working.

- It must absolutely be not taken out of the wooden crates. Remove the crates when you intend to install the paintball machine.

Conclusion

You have now reached to the end of the blog. The information in this blog was taken from reliable sources and materials. The blog was specifically written to make the reader understand ins and outs, pros and cons of a paintball machine and self-assessment and analysis of one’s own needs. Now you are in a better position of selecting the best paintball machine from the market according to your needs and requirements.

HAPPY SHOPPING!

Softgel Encapsulation Machine Related Products

Softgel Encapsulation Machine Related Posts

Softgel Encapsulation Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours