Tea Packing Machine: The Ultimate Buying Guide In 2025

Have you ever had an experience of visiting South Asian countries? If you have than you must have come across the term CHAI or DOODH PATTI a native term for tea served with milk.

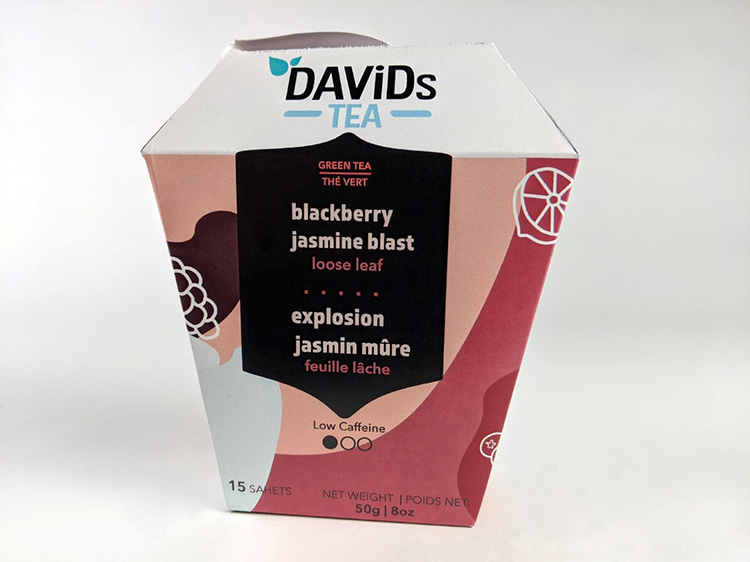

Tea is the most consumed beverage in the world after water. It is prepared by boiling fresh or cured leaves of Camellia sinensis, commonly known as tea plant.

Widely used for its medicinal and stimulating effects tea first originated in China and was brought to Europe by trading merchants. Tea contains catechins which are phenolic compounds acting as antioxidants and caffeine.

Do you want to quench your thirst of caffeine without much efforts? Just grab a cup, pour hot water in and add a commercially available tea bag.

The question however is why tea leaves were packed in tea bags in the first place? If you want to know more about tea bags, how they are manufactured and packed, which tea bag machines are popular than recommend you to read this blog.

Bringing you“Tea bag packing machine:the ultimate buying guide in 2022”before investing your money, grab a cup of hot tea, look out of your balcony and enjoy this blog!

1.A brief historical background of tea bags.

Tea bags are perforated small pouches containing tea leaves or other medicinal herbs intended to be brewed with water to make a consumable herbal decoction.

Tea bags can be dated back to the start of the twentieth century when a tea importer named Thomas Sullivan started successfully shipping tea in silk tea bags all over the globe.

As the popular legend goes tea leaves were originally packed in perforated bags which were meant to be opened before consumption but tea lovers found it more convenient to brew tea bags instead.

At that time tea bags resembled small sacks until the current rectangular shape was invented not before 1944.

The first tea bag machine was invented by Germans in 1928. Available in different shapes and sizes tea bags are made up of filter paper or plastic and sometimes silk or nylon.

Also you will find empty tea pouches in the market which can be filled with user desired tea leaves.

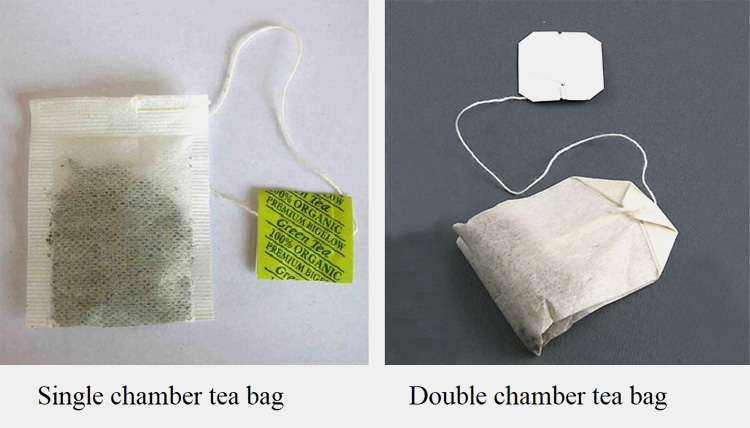

2.What are single chamber tea bags and double chamber tea bags?

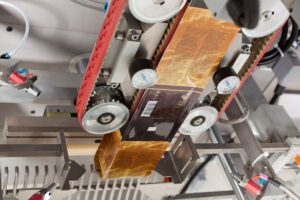

As the name implies single chamber tea bags holds tea leaves in a single chamber. It is the most popular type of tea bag in use since 1940. Available in mostly rectangular and square shapes the single chamber tea bags or regular tea bags are made up of heat sealed filter paper.

A string is also sometimes attached with glue or stapled intended to increase the contact area to make a better brew. However, the single chamber tea bag comes into contact with water from two sides only therefore, a longer dip in hot water is needed.

Tea bags filled by a traditional chai patti packing machine

The packing of tea leaves is done in such a way that two chambers are formed due to a tunneled opening in a double chamber tea bag. Double chamber tea bags are similar to single chamber tea bags but are sturdier and give a better brew in half of the time because of increased water contact from all four sides.

The make of the double chamber tea bags is usually heat sealed filter paper or nylon mesh and similar to single chamber tea bags a string is also attached.

3.What is manual and automatic tea packing machine?

Manual Tea Packing Machine:

Manual tea packing machine

Manual tea packing machine is a small tea packing machine which is considered the best equipment for individuals running home based operations or small businesses such as tea or coffee shops.

You can buy empty filter or nylon tea bags from the market and fill them with tea leaves or medicinal herbs of your choice. Some salient features of manual tea packing machine are mentioned below.

Ease of filling tea bags: In a small tea packing machine the tea leaves are displaced effortlessly according to entered parameters into commercially available tea bags. Since it is not operated on bulk quantities, therefore it is high flexible in customizing the packaging of the products.

Operation control: It allows the user such as you to adjust dosing and other machine parameters during the process based on protocol needs.

Minimum energy use: The energy requirement of a manual tea packing machine or a small tea packing machine is very less compared to the automatic system because it is manually handled by the user and does not run continuously.

Convenient: It is the most important feature of manual tea bag packing machine. Its operation principle is easy to understand and apply, does not require advanced technical skills and expertise. Also it does not require special installation requirement and can be placed on a table top.

Furnishing machine: This machine is used for small businesses such as restaurants, shops, markets therefore it is equipped with attractive furnishing.

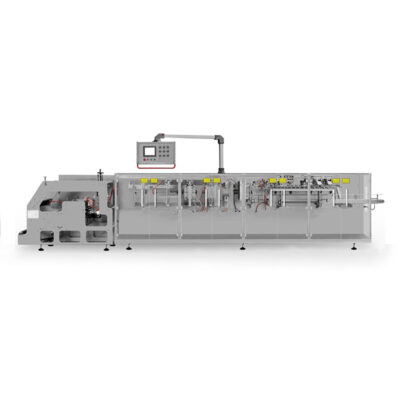

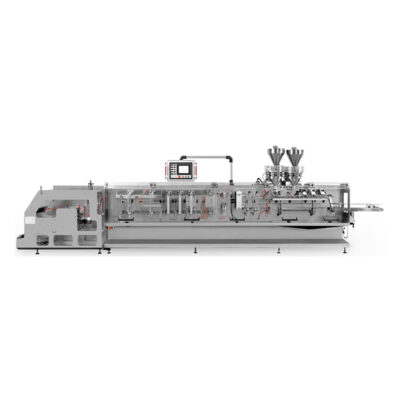

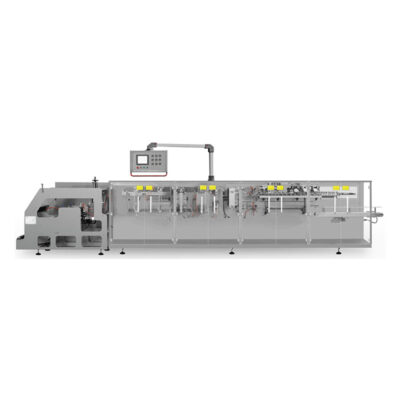

Automatic Tea Bag Packaging Machine

Are you looking to upgrade from your home business to a commercially successful brand in the market? And you are not bound with financial constraints, then automatic tea bag filling machine is the right choice for you.

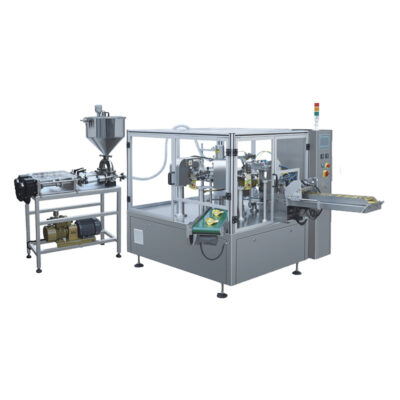

From tea leaves filling to sealing to packaging in cartons all can be performed by a single automatic tea bag filling and packaging machine. Some salient features are mentioned below.

Fully automatic tea bag packing machine

Automation: Your tea filling and packaging machine is equipped with an automatic system that performs functions like the feeding of tea, measurement of the size of the bag, manufacturing of bag, sealing, and cutting of tea sachets.

Capacity of machine: It makes 35-55 bags per minute. As per your need this limit can be increased.

Advanced sealing system: This automatic tea bag packing machine has an ultrasonic sealing system that is used for the packaging of tea bags. In older models heating units were used to seal the filters. Now you can seal herbs or tea leaves and other heat sensitive materials without losing their potency and efficacy.

Machine make and safety: Automatic tea bag packing machine is made up of stainless steel which is durable and environment friendly. The operation of this machine is more hygienic than manual packing. This machine does not make noise during operations and chances of occupational hazards are low.

Advanced electronics: Your automatic tea packing machine is equipped with advanced fail safe features. It is provided with a user interface which is easy to operate. Electronic sensors enable proper filling and sealing of tea bags, while the rejected tea bags are removed from the packaging line automatically.

Also it can make a three-dimensional package in a triangular and also in flat square bags according to your needs.

4.Are there any suitable tea packing machine for small businesses?

Tea businesses make a lot of profit all over the world. Purchasing a suitable tea packing machine for small business is very important for tea business houses. Many tea packing machines for small business have desired characteristics such as packing tea in less time, automatic filling of bags, etc. One such machine is the pyramid tea bag packing machine.

Pyramid tea bag packing machine

You will find many features in the pyramid tea bag machine that makes it suitable for tea bag sealing and packing, small scale operations and can be upgraded to or attached to a production line to meet the requirement of large scale manufacturing industry.

This small tea bag packing machine requires very small space for installation with low power consumption.

Uses

Pyramid tea bag packing machine is mainly used for packing and tea bag sealing ginseng essence, tea leaves, coffee, black, green, white, yellow, and flower tea.

It is also used for packing tea that is beneficial to health such as tea for curing stomach aches. Another important application of this tea packing machine is that it is used for measuring the weight of foods such as small grains and seasonings.

5.Whats is the technical specifications of an automatic tea packing machine?

You are aware of the fact that there are many models available that cater different requirements and needs of buyer. To give a general idea discussed below are some technical specifications of a standard version of an automatic tea pouch packaging machine.

You should consult the user manual provided with the machine for detailed and accurate specifications.

Motor and power supply: Standard tea packaging machine is equipped with a 3-phase 1.5KW motor which requires 220V power supply. These specifications can be changed based on the requirements provided by the user at the time of purchase.

Pneumatic unit: Pneumatic unit of your automatic tea packaging machine will generate the air pressure of about 6 bar or 250L/min.

Air pressure unit of a tea bag filling and sealing machine - Picture- Courtesy- allied automation

Tea bag size: Every standard version can produce tea bags of different shapes and sizes. Your machine can produce rectangular tea bags and with a push of a button you can change over to triangular or pyramid shape. Also your machine can produce tea pouches with or without string.

Pyramid tea bags by tea packing machine:Picture- Courtesy- selpak

Number of bags per minute: 50 tea-bags in a minute can be produced in a standard version. This limit however can be increased depending on your requirements. The size of tea bags is based on their shape.

A typical rectangular tea bag is 40-80mm wide and 50-80mm long whereas pyramid shape is in between 50-80mm all sides.

Different shapes of tea pouches with or without string produced in a tea packing machine

Packaging material: You can use filter film, nylon and any suitable material for ultrasonic sealing.

Weight and dimension of tea packaging machine: Automatic tea bag packaging machine does not require huge space for installation. Standard machine weighs approximately 200 Kg, it is 3ft wide and has a height of 7ft with a 2.5ft diameter.

6.What is the working principle and construction of an automatic tea packing machine?

Working principle

Like any other automatic machine your tea packing machine performs filling, sealing, counting and packaging of tea bags automatically. Inner and outer packaging films along with string roll are loaded on the machine first. You can use different materials for inner and outer packaging.

Automatic Tea Packaging Machine

After placement of herbs in the hopper, the tea bag filling and sealing machine is switched on. You can be sure that the hopper displaces accurately measured amount of herbs previously entered.

Machine then automatically performs sealing after which exact numbers of tea bags are packed in the cartons.

Major parts of automatic tea bag packaging machine

Tea bags are available in different sizes and shapes such as rectangular, single or double chamber and pyramid shaped, giving an intriguingly pleasant impression to the onlooker.

These different shaped tea bags can be produced either in a single production line or by different individual machines specific for each shape.

Sachet packed using tea powder packing machine

For your convenience major parts of an automatic tea bag packaging machine is discussed below.

Hopper: Tea leaves or any medicinal herb intended to be packed in a pouch is placed in the hopper. Made up of stainless steel the hopper is available in different sizes and controls the flow of material into dosing slide.

Dosing slide: Standard models are equipped with dosing slide. The dosing slide provides accurate weighing and dispensing of materials. Unique design reduces bridging and rat holes and produces more constant output. The dosing slide requires low energy for working and is operated by 3KW motor.

Dosing slide ensures accurate dispensing of material- Picture- Courtesy- kse-group

Inner and outer bag packaging film: Your automatic tea bag packaging machine can work with different types of packaging materials for both inner and outer covering.

You can use nylon or filter paper for inner bags and PE or aluminum foil for outer covering. Based on the type of materials used the parameter should be adjusted accordingly. Refer to user manual for details.

Counting sensor: The number tea bags per carton are entered beforehand by the operator using control panel. All automatic tea bag packaging machines have built in sensors that count the number of tea bags previously entered and pack them in carton.

Digital counter with emergency stop button- double chamber tea bag machine

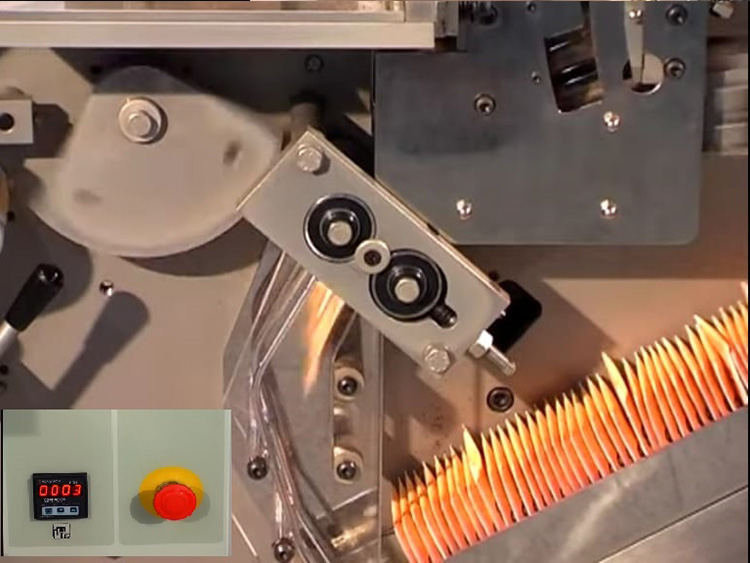

Sealing system and blades: Most machines are now equipped with ultrasonic sealing system, however some older versions may utilize heating compartment to seal the film together.

Ultrasonic sealing system is preferred for heat sensitive materials. It has added advantages over heat sealing as it prevents degradation of product or packaging material and avoids contamination.

The ultrasonic compartment can be set in between 20 – 40 KHz. After sealing the sachets are cut by tea sachet packing machine just above the seal with a stainless steel knife and are ejected out of chute.

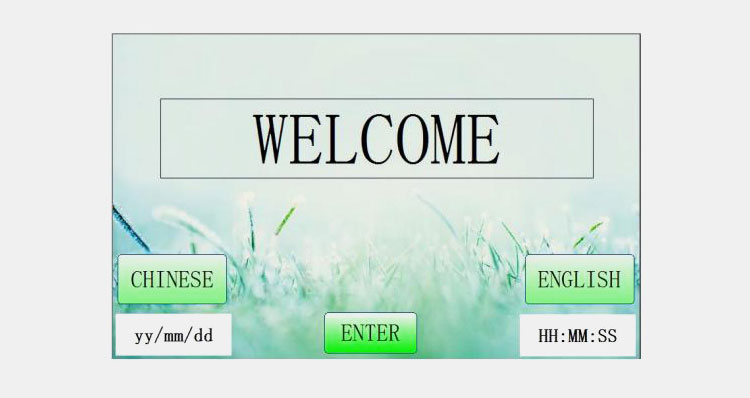

User Interface: All automatic models are provided with a digital user interface, equipped with PLC control system which is very friendly and easy to operate.

Language selecting screen of a tea packing machine

When tea packing machine is switched ON, a language display is shown. After selecting appropriate language a new screen will be displayed with all the options required to operate the machine.

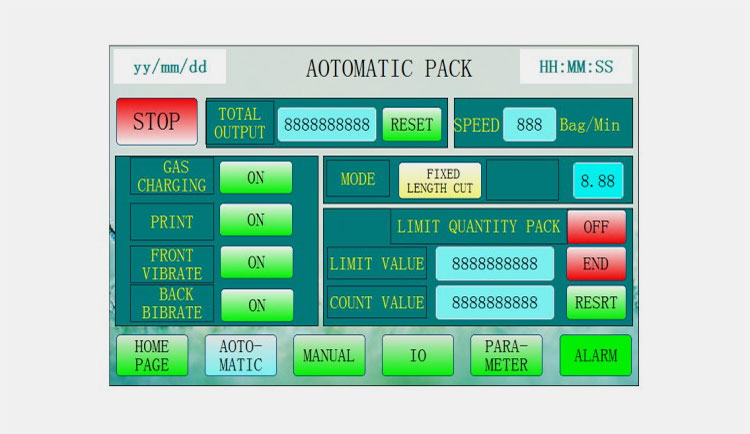

You can START and STOP the machine, adjust the parameters such as pneumatic flow, sealing temperature, number and length of tea bags per minute and many more.

Parameters selecting screen of a tea packing machine

7.Are there any advantages of tea packing machine?

Almost everyone including yourself start their day with a sip of stimulating tea or coffee, smart packaging attracts consumer and increases profit of company.

Tea packaging machine or tea bag making machine plays central role in tea industry, it offers following advantages to the manufacturer.

Superior Packaging: Tea packaging machine’s salient features include superior packaging. It means that it can pack the tea in exclusive re-sealable pouches. This art of packaging maintains freshness, improves quality and shelf life of tea products.

Time-effective: It is very convenient to use, flexible and rapid in its action. Tea bag making machine facilitates high production in manufacturing industries and therefore increases profit.

Reliable and accurate operation: Another key requirement of manufacturer is that the tea packaging machine should pack the exact amount of product in each bag. This equipment is well-reviewed by the customers for its feature of accurate weighing, filling and sealing tea products.

Cost-effective: The operation of tea packaging machine is automated, and fast, therefore it reduces the labor cost and energy resources of manufacturer.

Hygiene and Safety of Products: Tea packaging machine is made up of high quality stainless steel therefore, it is durable, ensures safety and high quality standards of products.

Environmental Friendly: The tea bag manufacturing machine does not produce waste. The process is started by evaluating machine performance by initiating packaging of empty pouches at least for 15 cycles which is then kept separated from the remaining operation and can be recycled later.

Overall, this equipment does not cause harm to user or produce any negative effect on environment if proper working protocols are employed.

8.How to use tea packing machine?

Pre-operating points

Before operating the tea bag packaging machine make sure that you follow pre-start up points. Some of these are mentioned below, for further information refer to user manual.

- First of all you need to assemble all the support structures provided with tea filling machine. These may include label support structure, cotton support structure and others.

- Before switching on the machine make sure that all the connections are tightened and screws are fixed. Tea filling machine is provided in a semi assembled form. A detailed inspection is required once the machine is installed at the site in order to eliminate chances of any faulty connections or parts that may have occurred during transportation.

- You should use recommended oil and for lubricating moving parts of tea filler.

- Connect the main electrical and pneumatic flow unit. It’s the responsibility of the user to ascertain electrical and air pressure requirements and mentioning them when placing the order. Usually the machine requires a 220V/1.5KW and pneumatic pressure of 200L (6 bar). Make sure that entire electrical connections are properly grounded.

- Switch on the machine before loading any packaging materials and observe the machine for few minutes for any unusual noises.

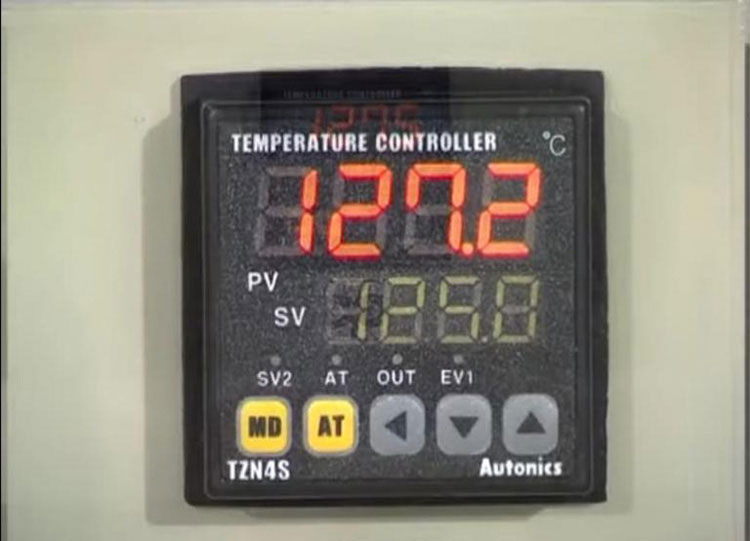

- Adjust the temperature of both outer bag packaging and inner bag packaging film material.

Temperature controller of a tea pouch packing machine- Picture- Courtesy- You Tube

- Switch off the machine and load packaging materials, label and cotton thread.

Operating tea packing machine

Once the tea packing machine is installed for the first time the manufacturer recommends that you perform an initial test to optimize the machine’s performance according to working conditions. Start the tea bag filler and run the machine empty and proceed with the following points.

START and STOP Push buttons- tea pouch packing machine- Picture Courtesy:You Tube

- Switch ON the tea bag machine, followed by temperature control unit (in some version ultrasonic unit) and pneumatic pressure unit.

- Make sure the feeding arms such as material feeding arm, thread feed arm and label feeding arm should be in an open and detached position.

- Load the filter roll on to the machine and push START button on the control panel. The packaging sealing should be flat so as to facilitate proper cutting.

- Close the thread and label feeding arm so as to ensure the tea bag is properly formed with an attached string and sealed in an outer covering.

- Close the material feeding arm. The material feeding time should be accurate.

- After opening the interior bag arm load the outer filter film.

- Set the parameters on the control panel such as length and size of the tea pouches needed and proceed with empty tea bags sealing and packing. Inspect the tea bags for proper sealing and packaging of both interior filter and outer covering.

- Once the operation is completed, stop the machine by using control panel. Cut the main power supply and shut down the air supply. Perform recommended cleaning procedures.

9.What are safety, installation and storage requirements of tea packing machine?

You should ensure that all safety guidelines provided by manufacturer, industry and local regulatory bodies are properly followed to avoid accidents and occupational hazards during operations.

It is recommended that the tea packaging machine should be installed immediately on arrival. If for any reason the installation is delayed is should be stored at an appropriate location free from dust, water and direct sunlight.

Installation Parameters

Flooring

- Tea bag packaging machine should be installed on a concrete leveled floor.

- A stainless steel platform can also be used instead of concrete base.

- Further leveling of the machine can be done by adjusting leveling screws present on the base.

Safety of Users

- Highly trained and experienced personnel should carry out the installation of machine.

- Safety gears such as goggles, helmets safety shoes should be worn when operating the machine or doing maintenance.

- Operators should inform the supervisor if they are under the influence of prescribed medicines or alcohol.

Installation Requirements

1.Unpacking

- Tea bag packaging machine is provided in wooden crates in a complete assembled form. Before opening the crates visually inspect for any damage that may have occurred during transportation.

- Use crow bars to remove the top of the crates first, then with the help of hammer and scissors remove sides and additional straps.

2.Transportation

The tea pouch making machine weighs approximately 200Kg, use of forklift is recommended for transportation to the installation site. You can also use hoist with the capacity of 500Kg. Direct human efforts are not advisable and can lead to permanent injury.

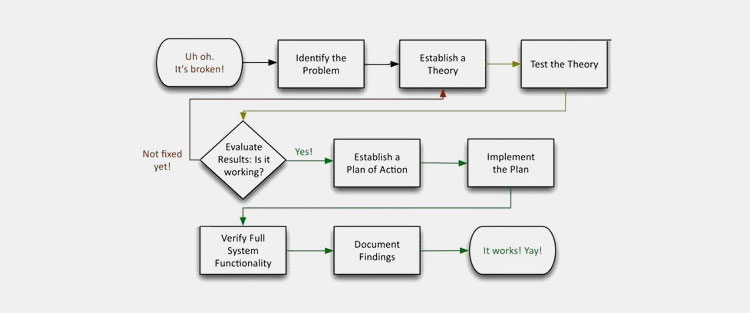

10.What are failure solutions of an automatic tea packing machine?

“We cannot solve our problems with the same thinking we used when we created them.” Albert Einstein.

When working on a machine you will come across certain situations where it will not respond the way you want it to even though it was left in a working condition.

This brings us to the part of the blog where you learn how to handle some troublesome situations. We will give you a short insight of how to deal with most commonly occurring problems during operations. For details please refer to the working manual.

- Failure of moving parts: This problem is related to circuit issues. You will have to check the connections. Normally the problem is resolved once the connections are secured. In some rare cases a replacement is required

- Creaking or abnormal sound: This is a serious problem. During operations the tea bag packing machine produces very little or no noise. If abnormal sounds are produced you have to immediately halt the operations and check for the fault.

- Spots around sealing areas due to burning: This indicates the heat sealing gears are not properly lubricated. You need to properly lubricate the gear.

- Improper sealing of tea bags: This problem arises due to a number of reasons. The sealing unit is damaged, unclean, quality of packaging paper is not up to the required standards or the sealing unit is experiencing unwanted pressure. To resolve this issue it is recommended that proper cleaning procedures are employed without any compromise in quality standards. You will need to replace the sealing unit if the unit is damaged.

- Leakage of tea leaves: When materials dropping time is out or packaging and heating units are not synchronized you will experience leakage of tea bags. Adjusting feeding and threading time or synchronizing packaging and heating units will resolve this issue.

- Improper cutting: Either the knife is damaged or become dull or the position of knife is not proper. You will have to replace the knife or sharpen it or bring the knife to its proper position.

- Cannot attach string to tea bags: You need to check thread holder position, position of pouches and mechanical arm.

- Tea bags do not fall in outer packaging: This problem usually arises due improper position of mechanical arm, improper thread cutting, improper formation of outer packaging. You will have to adjust the mechanical arm, check the cutting knife and adjust the forming position of outer packaging.

- String breakage: You need to check the pressure or the brass bracket. Usually reducing the pressure will remove string breakage but if the brass bracket is damaged it will have to be replaced.

11.How to perform maintenance of tea bag packing machine?

“There’s birth, there’s death and in between there’s maintenance.” Tom Robbins.

Maintenance is a must do critical aspect of any machine, if that machine is to be used efficiently for a long period. Maintenance should be performed by trained and experienced staff with hands on experience (hours). Given below are some key points for further instructions refer to individual user manual.

- After each batch of tea leaves or herb filling follow in-house cleaning SOP’s. Do not start maintenance immediately after operations, allow machine to cool down first.

- Place a note on the machine that states that machine is under maintenance so as to avoid unwanted startups.

- Remove the hopper and wash the parts which come in contact with tea leaves or other medicinal herbs with warm water. After washing use a clean cloth to wipe off the remaining water or use air pressure to completely dry washed parts.

- After every operation remove the inner and outer filter film rolls.

- If your machine is provided with advanced electronics such as photoelectric sensors, proper cleaning protocols should be employed to keep the sensors clean and dust free.

- Frequently check for loose connections or screws and replace parts as necessary.

- Lubricate the moving parts with grease every two weeks and apply fresh grease every month.

- Manufacturer recommends change of oil after 40 hours first time than after every 1000 hours. Use manufacturer recommended oils.

12.Can you customize your tea packing machine?

Yes you can! Standard version of tea bag packaging machine include all built-in features that are required to produce eye catching tea pouches, however additional features could be included in the tea packaging machine that can increase its working capacity and efficiency. These include

- Addition of multiple feeding devices for long bags.

- Up gradation of weighing system for accurate dispensing and reduction in batch to batch variations.

- Inclusion of dosing vibrator

- Acrylic covers for covering packaging rolls.

- Increasing production for large businesses

- Complete automatic production line setup.

Conclusion

OH! You have now reached the end of the blog. Just grab one more cup of tea and enjoy a quick overview of the entire blog. Tea is one of the most lovable drinks of the planet. Tea leaves are packed in small pouches of different sizes and shapes called tea bags.

You can make tea bags by simply buying commercially available pouches and sealing them with sealer but if you own a small coffee or tea shop and you want accurate dispensing just go and buy yourself a manual tea bag packing machine. Tea bag filling machine can also be employed for packaging and filling coffee powder or beans or any medicinal herbs.

Automation always benefit you in the long run, you can safe time, energy and increase production just by buying fully automatic tea bag packaging and sealing machine. We hope this blog was useful and informative and you are now fully updated on the ongoing market trend. Wish you best of luck. Happy Hunting!

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine