PACKAGES

PRODUCTS

BAG STYLES

Cartons/Cases

Once a product has been sealed in an individual primary packaging, it is often placed in a carton/case with a number of other identical products.

Carton/case packaging serves as an important role to pharmaceutical manufacturing,mainly applicable to pack pills, tablets, capsules, syrups, topical medications, powders, vaccinations, droplets, nutritional products and health supplements.

Carton packaging will not only perform the function of protecting your product but also for the ease of your transportion. Apart from protecting the products from adulteration and interference, carton packaging can also act as tamper proof.

AIPAK offers verious types of horiontal cartoning machines that are suitable for the packing of of pharmaceuticals, cosmetics, food stuffs, nutraceuticals, healthcare, medical and industrial products as well as for chemical products.

The cartoning machine will pick a single piece from stack of folded carton and erects it, fill with a product or bag of products or number of products horizontally through an open end and closes by tucking the end flaps of the carton or applying glue or adhesive.

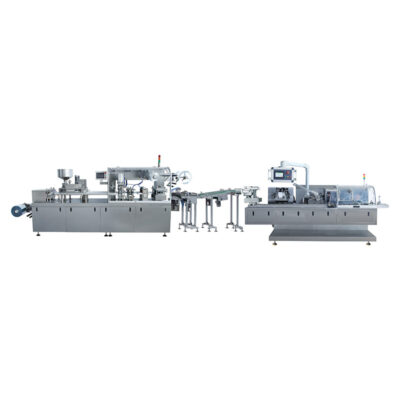

Besides,AIPAK also provides full automatic cartoning machine production line for your choice,with which you will no need thinking about what else suitable machines corporated with the cartoning machine to realize your large scale manufacturing.

Machines For Cartons/Cases

Videos For Cartons/Cases

Frequently Asked Questions

It is the market demands and the needs of the rapid development of the pharmaceutical industry that you need the automatic cartoning mahcine,which is in high speed and will release your labor cost.

AIPAK automatic cartoning machine has learned from export advanced technology,that has excellent performance and considerate service. It can reach a packing speed of 450 boxes per minute. In the packing process, we use PE film as the packaging material, and the packing speed can reach 40 bundles per minute.

Besides,AIPAK’s fully automatic high-speed cartoning machine production line is an organic whole that integrates feeding, boxing, and bundling of pharmaceuticals, food, medical equipment, health products, electronic components and similar materials. It has a compact structure and simple operation. , PLC touch screen control and other features. This machine can be used for packing aluminum-plastic board, ointment, pill tray, soft double aluminum, bag, etc.

A carton sealing machine is designed to seal the carton with proper tape adhesive. There are various benefits of case sealer that gives an ideal solution. Some of them are given below:

- Reduces cost

- Increase output

- Reduces the carbon footprint

- Increase the efficiency

- Reduces the usage of tape

- Increase ROI

- Decrease the damage of the product

- Enhances the security of the product

- Reduces the worker’s compensation claims

- Eliminate uneven tape lengths

- Reduces the injuries of the employee.

So these are the reasons that shows that the carton sealing machine is an ideal solution.

AIPAK pharma can be one of the best manufacturers of cartoning machines in China. “Technological innovation” and “excellent quality” are always the target principles AIPAK adhere to.AIPAK also focus on products R&D while ensuring technology leadership and innovative features.All components and materials used in AIPAK machines and equipment are imported from Germany,U.S. and Japan.AIPAK strictly follow ISO9001 quality management system and 5s on-site management practices to ensure AIPAK product quality and precise,timely supply.AIPAK have expert R&D team that is ready to provide fast and efficient help to customer at any time.

AIPAK cartoning machines are new type of machines developed by our company in combination with advanced technology both domestic and abroad. The cartoning machines are high-tech products integrating light, electricity, gas and machinery, which greatly improves the performance and working efficiency of the equipment, realizes the requirements of fast packing, and maintains a stable and reliable state in fast operation. AIPAK cartoning machines are suitable for automatic packing of blister plate, small round bottle (tray), etc. The automatic feeding mechanism is easy to adjust, and the number of plates to be packed can be set arbitrarily on the operation screen.

You may choose a horizontal cartoning machine or a vertical Cartoning machine as your actual to be packed products production needs.

Since a horizontal cartoning machine is an ideal equipment for packaging various solid regular objects, such as biscuits, bread, instant noodle, ice cream, moon cake, candy, blister medicine etc.

A horizontal cartoning machine completes the tasks of automatic feeding bottle(round, square bottle)into carton (either for blister or bottle),online bottle unscramble and feeding, leaflet fold( 1-4 folds) and feeding, leaflet detecting, canton opening and forming, products and leaflet pushing into carton, printing batch number, sealing carton with hot melt glue device, automatically reject lacking of leaflet or product until finished product out.

While a vertical Cartoning machine is most suitable for packaging bottles, jars and vials into cartons,so it is most preferred in cosmetics,food and pharmaceutical industry.It is vertical that you will not hard to understand its compact and flexibility features,thus,meet most products high packaging requirements.Besides,so much experience and statics have told us vertical products inserting will have lower risk of product damage.

In our daily life, we often eat chewing gum, lozenges, chocolate bean and white rabbit toffee and other sweets. They are beautifully packaged, and people can’t help but want to open and eat. So how do they realize these packaging? The following recommends a AIPAK horizontal cartoning machine is suitable for candy packaging.

AIPAK horizontal cartoning machine is mainly suitable for automatic high-speed blister packaging of regular medicines such as capsules and tablets and chewing gum, lozenges, chocolate beans and other sweets. It adopts flat positive pressure forming, the blister is firm and uniform, and the drum type mesh seal , Reliable sealing, equipped with batch number and indentation devices, can be designed for blanking without waste, with high automation, high productivity, and superior performance of greatly saving packaging materials.

You may consider the following aspects when you intend to purchase a high speed cartoning machine:

Machine design

Most full automatic high-speed cartoning machine manufacturers will introduce the design and construction as a durable machine, which can better resist external forces and vibration, and comply with the harsh consumer environment.

That is,you shall ask for the type of parts to be used and the name of the manufacturer. If the customer has a request, some suppliers will provide a standard spare parts list.

Customization

Be able to choose a supplier who can provide customized cartoning machine, and meet your real needs through minor changes to the design.

Credibility, reliability

You should also consider the reputation of the supplier in the industry and whether his financial situation can be stable. To ensure that after the machine installation, the supplier can provide you with support and service in the future years.

Sensitivity

Whether now or in the future, packaging needs may change. So when choosing the cartoning machine, this cannot be ignored. If you estimate that cartons or product sizes will change in the future, make sure that the machines you buy can be retrofitted or can handle cartons of different sizes.

Size of machine

When choosing a supplier, you should see whether he can provide multiple models of cartoning machine, so that you can easily find the right model for your packaging line.

If you buy a front-end product disposal equipment that takes up too space, then you can also buy a cartoner that takes up a small space.

Intergratity of machine

Cartoning machine is generally located in the middle of the consumer line, then you should ensure the cartoning machine you are purchasing can be connected and communicated with the upstream and downstream equipment.

As a whole production line also includes a variety of other machines, such as upstream bagging machine and wrapping machine. If you buy only one cartoner, make sure your supplier knows how to integrate the full line.