High Quality Bin Mixer

- Highly Uniform Mixing

- High Efficient Energy Saving

- Larger Loading Capacity

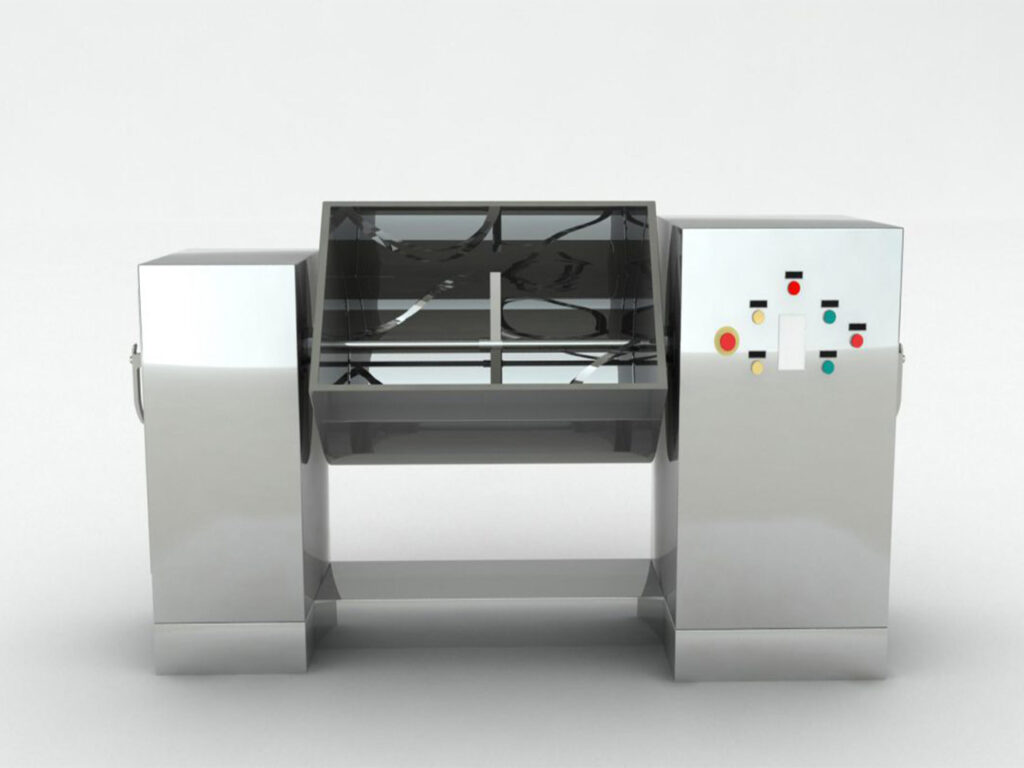

AIPAK Bin Mixer

AIPAK Bin Mixer is suitable for mixing dry granule materials for pharmaceutical, chemical, foodstuff, and other industries. Based on importing, absorbing, and digesting the new technology of foreign countries, all AIPAK Bin Mixers feature a simple structure, compact structure, high mixing efficiency, small occupation area, and lower power consumption. With high mixing speed and good mixing effect, the mixing uniformity rate can reach over 95%, inner of all AIPAK bin mixers are of new type sealing structure, during mixing, it is free of pollution, with convenient operation and maintenance.

AIPAK Bin Mixer Working Principle

The Buyer's Guide

Bin Mixer: the Complete Buying Guide in 2024

If you are looking for a pharmaceutical mixer to mix your powder or granules, a bin mixer is highly recommended to you.

Then you may begin to wonder, what is a bin, why there is a bin.

A bin mixer in all pharmaceutical mixers not only guarantees the homogenous mixing, but also eliminates you from loading, unloading, and cleaning the mixer.

Of course, the following guide is for you to choose the quality and reliable bin mixer.

Let’s begin our topic soon.

1. What is a Bin Mixer?

AIPAK Bin Mixer

Bin Mixer is used in many industries for mixing multiple types of products like powder, granules, and other solid products for fluid and gentle mixture.

Mixing is done with the help of a rotating bin with the help of rotation at a specific angle like 45 or 60 degrees the inside material is mixed.

It is easy for you to put the material and remove it after the mixing is done because the bin is moveable in many directions.

It performs dual action when the mixing products are put inside the Bin Mixer, starts rotating, and tumbles the inside material.

You can get uniform mixing of the products with the help of this machine which allows you to have the best mixture by putting the materials inside.

2. What are the Advantages of Using a Bin Mixer?

There are some following benefits that you can get while using the Bin Blender.

Uniform Mixing can be done with the help of this machine.

- It is very consistent and reliable to use for mixing granules and powder at the same time but it depends on the dimensions of the machine.

- With less time consumption you can get more accurate mixing of the material while using this machine.

- Air Driven jacks inside the machine bin make it safer to use and guarantee your product safety.

- If there is any problem occurred during the mixing the machine has a safety button that ensures the safety of the inside material and also the machine.

- It is easy to operate the Bin Blender because the PLC Control Systemmakes it easier for you to control all the operations.

- You will get a high-quality product with the help of this machine and it will help you to compete with the market.

- The safety of your inside product is secured with the help of this machine.

- User friendly and anyone can operate the machine without having basic knowledge about it.

- Bin Blender is very superior; you can operate it for the whole day without any stoppage.

- Only fewer persons can be required to operate the machine so it can help you to save your labor expenses.

- This machine uses up-to-date technology for its working which makes it more reliable and easy for mixing.

- You can get more production in less time frame so your production rate will be increased.

3. Are there any Drawbacks of the Bin Mixer?

There are some following drawbacks/disadvantages of the Bin Mixer.

- If the batch size is too large then the machine will take some time to mix the material as compared to the normal time.

- Because the size of the bin is small you can not mix large amounts of the materials inside the bin.

4. Which Industries are Bin Mixers used?

Some following industries are using Bin Mixer for mixing different types of materials.

Pharmaceutical/Medical Industry

In the Medical industry, different types of tablet powder are mixed with the help of this machine to get an accurate amount of mixing product.

Granules can also be mixed with the help of this machine; it can mix any type of material according to your requirements.

You can mix two different types of materials at the same time as granules and powder but it depends on the machine working.

Food Industry

Mixed sugar

Sugar grains used in making different eatables can be mixed with other materials to get an accurate amount of mixture and an accurate taste can be obtained using the Bin Mixer.

Other food products like powder, liquid, and other hard products can also be mixed using the Bin Blender.

Liquid and Sugar can be mixed with the help of this machine.

Chemical Industry

Mixed plastic powder

In the chemical industry, Bin Blender is used for mixing different types of liquid chemicals as well as powder chemicals.

You can mix an accurate amount of drugs into the powder or granules to make an accurate chemical.

Cosmetics Industry

In the beauty industry for making different types of products, a mixture of two or more types of materials can be obtained using this machine.

Cosmetic Chunky Glitter Mix Powder

For example, the products like face powder, nail paints, lotions, etc can be obtained using the Bin Mixer.

5. How many types of Bin mixers are in the market now?

There are some following types of Bin mixers/blenders used for mixing different types of materials.

They lie in different sizes and different shapes according to their specifications and working capacity.

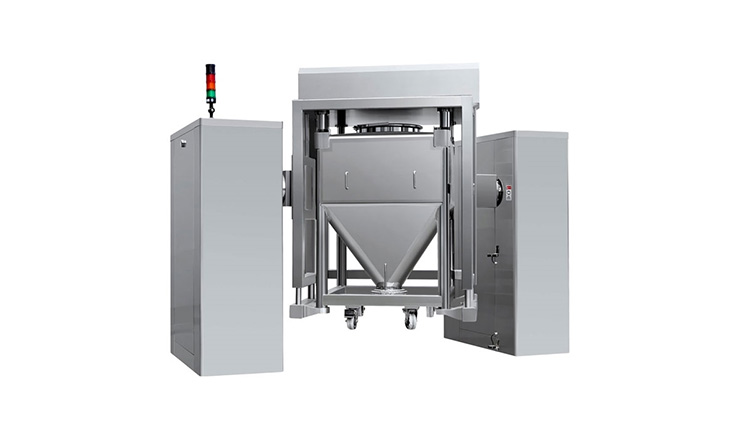

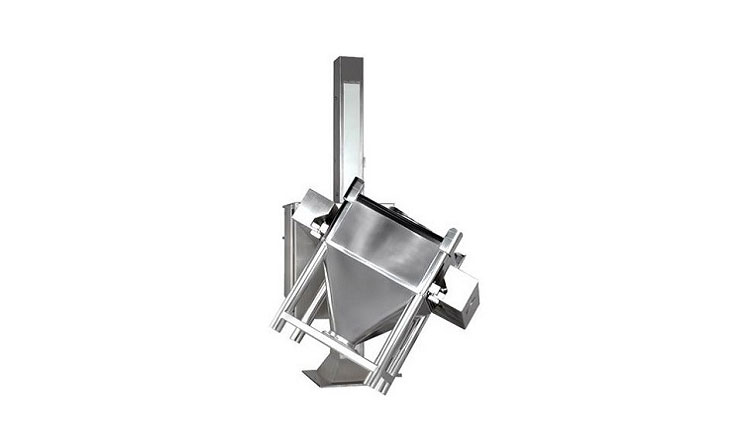

IBC Bin Blender

AIPAK Bin Blender

This Blender is highly efficient and specially designed for quick work for blending powder and granules in the Medical industry.

With the help of this machine, you can load and unload the inside material very quickly as it is very flexible to use.

Cleaning of this machine is very easy and less time-consuming because the inside parts are manufactured with stainless steel.

IBC Blender is used on an industrial scale as it is designed for getting a huge amount of production.

The blending container can blend up to 2000 liters capacity of the mixture.

Post Bin Blender

This machine is fully automatic and can work in different forms from loading the material, mixing the material, and then unloading the mixture.

Highly used in medical, food, and other industries for mixing different types of products.

Post Bin Blender- Picture Credits: unit-fine

This machine is considered ideal mixing equipment for all industries. It is easy for you to change the batch size.

You can get efficient blending in very little time by using this machine. As the size of this machine is small you can easily adjust it in less space.

Laboratory Bin Blender

Lab Bin Blinder is used for mixing powder and granules for getting high-quality production at less cost.

This machine is mostly used in the medical industry for getting more production in a short time frame.

Laboratory Bin Blender-Picture Credits : MG America

The speed and time frame of the mixing material is set digitally in this machine. Lab-size blenders are used for small purposes of production.

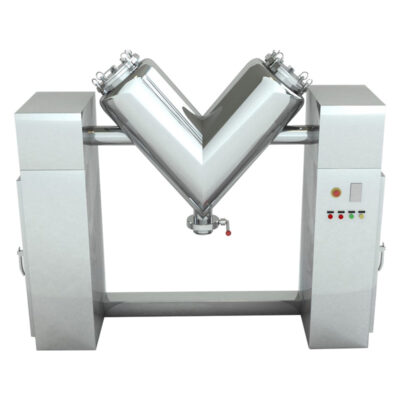

V-Type Blender

Small Size V-type Bin Blender -Picture Credits: Ability fabricators

As by its name, this machine has a V-shape bin mixer which divides the inside material into two portions and during the rotation, the inside materials uniformly mix.

This machine is very easy to charge and unload after the mixing. It is easy for you to clean the machine.

V-Type Blender is highly demanded in the medical and chemical industry for mixing powder and granules.

Double Cone Blender

This Blender is very effective in mixing solid materials with efficient working it is used in many industries like Cosmetics, Medical, Food, Plastics, Detergents, etc.

It contains two cones on the upper and lower end which makes it effective for homogeneous mixing.

Double Cone Bin Blender-Picture Credits: Shanghai Chemix & Co

One of the main functions of Double Cone Blender is to mix dry powder and granules homogeneously.

It is also very effective for wet mixing of different products. You can also dry the wet components with the help of a thin Blender.

Vertical Blender

This machine is all in one that can give you flexibility for mixing different types of materials from powder to powder, liquid to powder, solid to liquid, or liquid within liquid.

Highly efficient as per the production rate you can get more production by using this Blender to compete with the market values.

Vertical Bin Mixer-Picture Credits: Pharmaceutical online

A spiral blade inside the bin helps the materials to mix very well without doing any damage to the product's quality.

6. What are the Main Components of a Bin Mixer?

There are some following Main Components of the Bin Mixer that help the machine to deliver quality work.

You must know some basic components of the Bin Blender when you are going to choose the machine according to your needs.

Here are some main parts of the Blender.

Rotation Counter

This part of the machine is very important for mixing the materials inside the bin, very useful in many ways from lifting the mixing container and unloading it.

Rotating Bin/Counter-Picture Credits: jbm prispac

The size of the mixing container depends on the rotation counter and how much weight your rotation counter can lift.

It is very efficient in mixing your product up to very high quality.

Clamping Bars/Stands

As you see when any machine starts working it becomes unstable and starts vibrating so these Bars help the Bin Mixer to remain intact during the operation.

These Bars help the machine to remain stable during the operation and don’t let the machine slip through the floor.

Control Operation

The PLC Control System of the Bin Mixer helps you to operate the machine with the help of a touch screen.

PLC Control System on the left side of IBC Bin Mixer -Picture Credits: Rapid Mixer & Co

It helps you to perform all the operations effectively just by knowing some basic settings of the machine.

You can easily perform all the operations using the Control System of the machine.

Light Guard

This part of the Bin Mixer makes the machine more quicker and efficient during the mixing process.

Infrared red light beams help your product to remain perfect in quality by doing the flash mount onto the walls of the mixing container.

It is easy to operate this component of the Bin Blender along with other components.

Blending/Mixing Container

Mixing Container is a necessary part of the Bin Mixer and it is available in different shapes and sizes.

The material that you put inside remains in the Blending Container and all the mixing operation is done inside it.

Mixing Container in Bin Blender-Picture Credits: Nantong Fengwei

According to the shape and size, you can get different types of uniform mixing on different types of products with the help of this component.

Laser Guard

Just above the floor level, these sensor-based components help to secure the safety of your product and the working person.

It detects if there is any other material coming inside the machine or finds any kind of fault inside the Bin Mixer then it automatically stops the machine.

The alarm system of the machine is based on this component because the safety of the operating personnel and your product is very important.

7. How does the Bin Mixer work?

As you know the Bin Mixer is available in different shapes and sizes but the working principle of all Blenders is almost the same.

You can watch the complete working video of the machine

Video Credit: Matcon Ltd.

Working Principle

This machine works through the following steps that are discussed below.

Filling Capacity

The filling Capacity of all the Bin Blender’s is not the same so you must fill the product according to the filling capacity of the mixing container.

Always fill the bin mixer up to the specific capacity as per the capacity of the container.

Time and other Settings using the PLC System

After the filling is done check all the parameters according to the manual then set the time for mixing the material.

Set the rotation of the container clockwise or anti-clockwise according to the requirements of your product.

Start the Bin Blender when all the settings are set.

You will get a uniform mixture by setting the right timer and rotating the Bin Mixer by using two or more ingredients/materials.

Product Discharging and Stopping the Machine

When the mixing is done stop the machine unload or discharge the product into the container and see if you get the quality mixture.

Always check the quality of the product when the mixing is done so that you can make any changes if the mixture is not uniform.

8. What is a 3D Motion Mixer?

Three Dimension Mixer is used to get a homogeneous mixture of different products. It is used in different industries for mixing purposes.

As by its name, this Mixer can move in three different directions to get the perfect mixture.

AIPAK 3D Bin Mixer

The mixing container of this machine is made up of stainless steel so the inside product will not stick with the walls of the container when multi-motion is done by the machine.

It is easy for the container to make the movement even when it is filled up with a very high amount of product.

It will mix your material uniformly by making the circulatory motion from top to bottom and bottom to top with the help of a rotation container.

It is available for industry level as well as for industrial level. Easy for you to clean the mixing drum/container.

You can watch the complete working video of the machine

Video Credits: Stemon W.

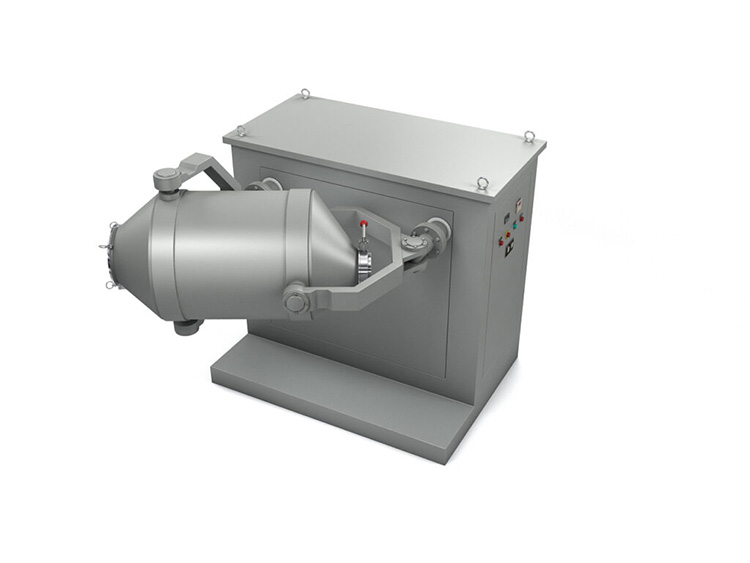

9. What is a 2D Movement Mixer?

AIPAK 2D Bin Mixer

Two Dimension Mixers move to the mixing drum in two directions to get a uniform mixture.

It is made up of the following parts which work in the 2D Mixer.

- Rotary Barrel.

- Swing Frame.

- Swing Frame supported with 4 Rollers.

- Transmission System.

- Crank Shaft.

These components of the machine work together to mix different types of materials. It is used for mixing powder and granule materials.

You can get a uniform mixture in less time because the two-directional movement of the mixing drum made the best mixture.

10. What is a Cone Bin Mixer?

The conical shape of the mixing drum helps to get the uniform mixing very easily with high-quality production.

Built-in the component of the machine, the Mucon Valve which is present at the bottom of the machine makes the discharging of the mixture easy for you.

Conical Bin Mixer -Picture Credits: Directindustry

Pollution-free production can be obtained because the Cone Bin Mixer is enclosed from all around which makes high-quality products.

It is mainly used in the pharmaceutical industry for powder mixing. You can set the mixing time digitally.

A single Cone Blender or Cone Blender rotates the inside material and trembles it to get a uniform mixture.

11. What is the Function of the Lifting Column in a Bin Mixer?

There is a component of the Bin Mixer/Blender called Lifting Column which works to lift the mixing drum when the product is loaded inside.

This part of the machine makes it easy for you to load the container and when the filling is done the Lifting Column lifts the mixture drum.

It also makes your work easy to unload the mixture from the mixing bin when the homogeneous mixture is done.

Lifting Column in Bin Blender-Picture Credits: Senieer

Every lifting column holds a unique functionality and different work rate according to the size and shape of the equipment.

It is also designed for dust handling in the Bin Mixer and helps to give you high-quality products without any pollution.

It also ensures the safe working of your machine in every aspect with or without any operation.

Lifting Column helps the Bin Mixer to work quickly and precisely by giving more stability to the machine.

Some other uses of the Lifting Column/Lifter Column

- Help to control the linear movement of the mixing container.

- Give perfect adjustment and stability.

- Highly used in the Medical Industry.

- Noise-free when doing the operation.

- Load and unload the mixing material.

12. What is the difference between a Single Column Bin Mixer and a Double Column Bin Mixer?

Single Column Bin Mixer/Blender

This Blender is used in the food, healthcare, and pharmaceutical industries to get a homogeneous mixture of granules and dry powder.

It works perfectly without cross-contamination and your product will remain dust-free. It is easy for you to remove the bin and replace it if it gets damaged during the operation.

Single Column Bin Mixer-Picture Credits: Senieer

Features of Single Column Blender

- It is easy to adjust in a small area because of its small size as compared to other blenders.

- The safety system works very smoothly for the rotation of the mixing bin and is very reliable during the mixing.

- As the machine is automatic it is easy for you to operate all the functions.

- The rate of uniform and homogeneous mixing is increased with the help of the Single Column Bin Mixer.

- You can easily unload the product after the mixing because the built-in lifting column helps you to do so.

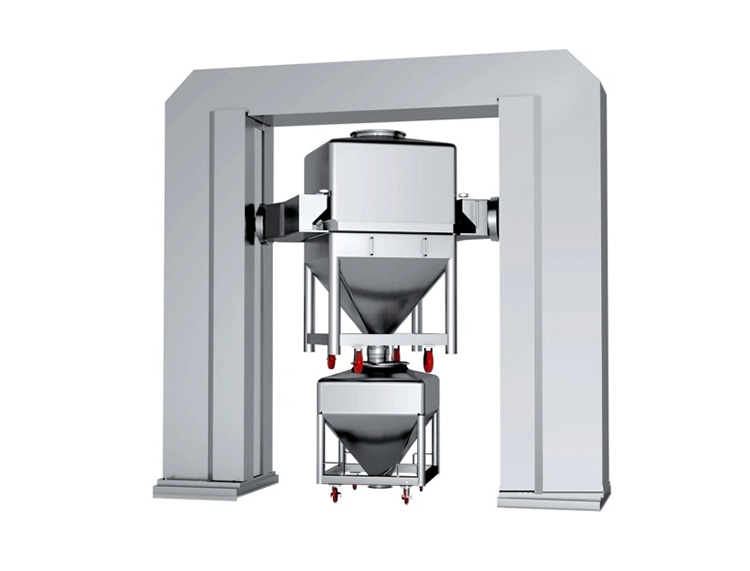

Double Column Bin Blender/Mixer

This machine is much more effective than the Single Column Blender because it works through the two columns for mixing the product homogeneously.

You can get a higher quality product by using this machine as compared to the Single Column Blender.

Double Column Blender is used in many industries for getting homogeneous mixing of granules and dry powder.

It works very quickly by using the Dual Column Mixing system and you can get more product in less time.

Double Column Bin Mixer-Picture Credits: Rotech Group

Features of Double Column Bin Blender/Mixer

- This machine will require more area for adjustment because of two columns.

- The cost of this blender is more as compared to the single column.

- With the help of Double Column, this blender can bring more quality to your product.

- The bin mixer is set between the two columns manually and then the rotation performs automatically.

- Because of the two columns the Bin Mixer can contain up to 2000L of mixing material.

- Double Column Bin Mixer is more stable as compared to other blenders.

13. Which Factors Affect the Working Efficiency of Bin Mixer Most?

Some following factors affect the working efficiency and production rate of Bin Mixer.

Components and Size of the Mixer

Of course, the work rate of the machine depends on the size of the machine and what type of components are used for making the Bin Mixer.

In general, the horizontal mixer takes less time to mix as compared to the vertical mixer. These are some basic physical factors that can affect the working efficiency of the machine.

Mixing Material

The raw material that you are going to use for mixing purposes can also affect the efficiency because if the material inside the drum mixer is a liquid then it will take more time as compared to the dry powder or granules.

So your device may start heating because of the heavy material that you put inside for mixing purposes.

Company/Brand of the Bin Mixer

The brand of the machine also depends on its work rate because the standard machine with a higher production rate will be costly for you to buy.

Certification of the machine is also available when you are buying it from a branded shop/market.

Some Bin Mixers are made up of stainless steel and others may be made up of simple steel which can be harmful to your product quality.

14. What Quality Standards Should Bin Mixer Conform to?

There are some general standards that your machine must fulfill for quality production.

CE

This standard of your machine tells you that your machine must be safe to use in any type of environment.

After the making of the Bin Mixer, it must be practiced well so that the safety of your production and your environment remain safe and secure.

CGMP

It tells about the material that is used during the making of this machine and that material must be approved by the FDA.

Quality material ensures the long life of your Bin Mixer and its working accuracy can also depend on the components of the machine.

EN

This tells you about the economic European standards of your machine. It means your machine must fulfill European standards.

ISO

It means that the Bin Mixer must be designed and prepared according to the user requirements for quality regulations.

ASTM

This global organization gives some standards for making any machine. If your product reaches these standards then you will get a perfect machine.

It publishes all the standards that are agreed upon by the industry for making a Bin Mixer.

You can achieve quality by working according to these given standards.

ROHS

It is a safety standard that is set by the European Union for the safety of your product which means that your product does not contain any hazardous substance during the making of the machine-like lead or mercury.

Restriction of using dangerous materials protects your product from getting any kind of damage.

CCC

Every product that is sold in the Chinese market must fulfill this standardization so that the machine that you are buying must be safe and of good quality.

With the help of this standard, you can check whether your Bin Mixer/Blender is good or not.

Material

Every industry wants a dream Bin Mixer that can fulfill their needs to enhance their production rate.

You must consider which type of material is used for making the components of the machine, drum container, lifting column, etc.

15. What is the AIPAK Bin Mixer Specification?

There are some following specifications that an AIPAK Bin Mixer holds for uniform mixing of your product.

- AIPAK Bin Mixer is very reliable to use for mixing different types of materials like dry powder, granules, liquid, etc.

- It is based on a high absorbing system that is used in all foreign countries with a compact design, simple structure, small occupation area, and low electric power consumption.

- All the AIPAK Mixers can reach up to 95% uniform mixing with the inner side of the bin.

- It will give you a pollution-free quality product because of its new sealing structure which is based on easy maintenance level and useful operation.

16. How does AIPAK Bin Mixer guarantee Uniform Mixing?

You can get uniform mixing by using AIPAK Bin Mixer which gives some desired operation for good quality mixing.

Here are some following the functions that AIPAK Bin Mixer Performs to give you uniform mixing.

AIPAK Bin Mixer

Mixing Batch/Drum Size

From 50 to 60 %, the working ability of the Bin Mixer/Blender depends on the size of the container in which your material is going to be loaded.

The filling capacity is one of the critical criteria for getting uniform mixing and AIPAK Bin Mixer has enough batch size for uniform mixing.

If the mixing drum is filled badly or with more quantity then it will be difficult for you to get the uniform mixing.

Fill the AIPAK Bin Mixer up to the given amount of mixing material then it will give you uniform mixing.

Mixing Speed and Time

AIPAK Bin Mixer gives you an easy working operation to set the mixing speed and time according to the filling material to get uniform mixing.

By adjusting the moderate speed and timer from the PLC control system of the AIPAK Bin Mixer it will guarantee you the uniform mixing of the material.

Filling Material Amount

Fill the mixing drum with the right amount of mixing product then set the timer and speed of the rotation according to the given manual then you will get uniform mixing.

Uniform mixing of powder and granules is different because the dry powder will take less time as compared to the liquid and granules.

Presence of Baffles

The baffle's presence in the AIPAK Bin Mixer guarantees you the uniform mixing of the material because baffles are very useful in mixing and are rare to be found in Bin Mixers.

Baffles can improve the mixing quality and the chances of getting uniform mixing are increased with the help of baffles inside the container.

During the rotation, the baffles will also crush the product for perfect mixing inside the Bin Blender.

Presence of Agitator & Input Power

Some of the Bin Blender developers add the impeller in the blending mixer and AIPAK is also one of them to provide you that facility.

When the mixing drum is rotating the agitator provides the convective effect of mixing for your material so you can get uniform mixing.

The input power for the rotation of the blender is very low. AIPAK Bin Mixer can operate the blender rotation within a 1kw range.

17. What should you consider when Buying A Bin Mixer?

Whenever you are going to buy the Bin Blender you must keep in mind the following considerations for the best quality machine.

Quality Compliance & Standard Certifications

Some general and basic standards are set by the European Union and other unions for the quality production of the machinery.

Those standards tell about the material used for making the machine and the safety of the production machine-like, CGMP, CE, EN, FDA, CC, etc.

These standards tell you about Bin Mixer and how much it is for you to operate it under which circumstances you can operate it. And also your Blender must be made up of hazardous-free material so your production will remain good in quality and shape.

Durability Of The Working Components

Always look for a durable machine by looking at its moving components and checking the quality and material of the components that are used for making the Bin Mixer.

The inside material of the machine must be made of good quality because the bad material may react with your mixing product and will be harmful.

Always look for an ideal machine so that you can use it according to your requirements and fulfill your working criteria. It will also help you to set or change the working tools of the machine according to the mixing ingredients you are mixing.

Purpose Of The Machine

For what purpose or for what use you are going to buy the Bin Mixer are you going to mix the powder only or other material as well?

Before you buy the machine consider the mixing purpose of your production like what type of material you are using for mixing it is one of the major factors while buying the Bin Mixer.

Different types of machines are designed for different types of product mixing so choose wisely by keeping in mind the substance or ingredient that you are mixing whether it is chemical, powder, or granules.

Mixing Speed

The mixing speed of the machine depends on the mixing material because some of the mixing materials require a faster speed for mixing and others may need a slow mixing speed.

So you need to know that your Bin Mixer must be capable of changing speed and time. You can adjust the mixing speed easily as required.

Quality Product & Other Functions

Always choose the right machine by wandering all around the market. Your machine must be good in quality so that your production remains in perfect quality without getting contaminated.

Rather than doing the mixing, there need to be some other functions as well like lifting the material with the help of lifting columns, loading, and unloading of the material.

18. What are the Common Problems of Bin Mixers? How to Solve them?

Working with the Bin Mixer you might get some problems so you just need to know how to troubleshoot these problems.

Here are some common problems which may occur during the mixing.

Too Long Mixing Time

The mixing time of the Bin Mixer will depend on the batch size it. If the batch size is larger then mixing will take more time.

- Solution

Put the mixing product less in amount and set the mixing speed inaccurately after doing that see the output by putting different amounts of mixing material after every cycle.

Repeat the cycle and see the output and then adjust the amount of mixing product in the Bin Mixer and the speed of the rotating bin.

Little Capacity

The capacity of the container/drum of the Bin Mixer may be a little low so this will affect your production rate.

Solution

You can solve this problem by reviewing the time that you set for the mixing. Reviewing the time will help you to know how much time is taken to mix the specific material.

19. How to Maintain a Bin Mixer?

There are some following tips to maintain the Bin Mixer in good shape for quality production.

Lubrication & Oiling

It is a basic technique to maintain any machine, always check the moving parts of the Bin Mixer are moving smoothly without any fiction, fill the oil level, and lubricate the moving components according to the manual.

Oiling to Different Parts of the Machine

The lifetime of your machine and production rate will be increased by doing the lubrication to all the moving components of the Bin Mixer.

Drive components inside the mixer are very expensive to buy or replace so you just need to lubricate them to extend their lifetime.

Seal Maintenance

If the seal of the Bin Mixer gets damaged then the material inside will start coming outside of the mixing drum during the movement of the shaft.

There are many types of seals present in the market select the seal according to your machine's requirements.

Lip Seal is one of the best seals that check any leakage of the material daily.

Discharge Gate Cleaning

When the mixing is done the discharging gate of the Bin Mixer helps to unload the mixture and during the unloading, some of the material may get stuck with the discharge gate so you must utilize some energy to clean the gate after discharging the mixture.

Some foreign material, powder, or maybe dust particles get stuck on the discharge gate so observe the change during the process and see if the gate is open and closed perfectly.

Protect The Mixing Tube

Mixing Tube is one of the most important parts of the Bin Mixer so you must need to protect it from getting any kind of damage.

Clean the Mixing Tube after every process and check if there is any kind of foreign material inside along with the mixing material like a piece of metal or stone can heavily damage the mixing tube.

Electric Safety

Electric cords present in the Bin Mixer save your device from any kind of electric shock.

Always check the safety cords in the machine so that your workers do not get any kind of injuries due to short circuits and it can also save your machine from fire.

Before starting the machine check the electric cords because if the electric cords are damaged they can be harmful to use for mixing purposes.

Conclusion

Always choose quality or quantity because the quality products you will get from the Bin Mixer will be much better than the quantity in less time with useless mixing.

You must set the aim of getting the perfect Bin Mixer for your firm so that it can meet your requirements. Consider every part of the machine must be good and designed perfectly.

A Bin Mixer of the best quality can give you the best output according to your requirements/needs.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586