Automatic Capsule Filling Machine: The Ultimate Buying Guide In 2025

Automatic capsule filling machines are largely used in the pharmaceutical industry worldwide for production of hard gelatin capsules in formulation with powder, pellets, and granules separately or in different type’s combination of powder & pallets.

Now there are many different types of automatic capsule filling machines in the market,you may find it hard to choose from.

Then,I will give you a complete guide.

Reading through,you will get some of the true principle of buying the most suitable automatic capsule filling machine.

1.What is Automatic Capsule Filling Machine?

AIPAK automatic capsule filling machine

An automatic capsule filler or Automatic capsule filling machine is used to fill multi types of capsules including the hard gelatin capsules and the soft ones.

With the help of this machine, you can get accuracy in your filling product and will help you to increase the production rate.

An automatic capsule filling machine uses the joint capsules to separate them fill them and then join them again with perfect binding.

2.Which Types of Capsules can Automatic Capsule Filling Machine fill?

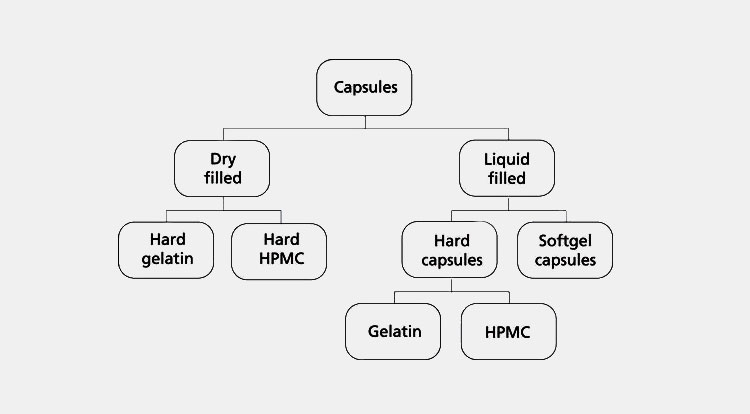

Mainly there are two different types of capsule shells that are used for filling.

Gelatin Capsules(Hard Gelatin, Soft Gelatin)

Vegetarian Capsules (HPMC Capsule, Pullulan Capsule)

Types of Capsules-Picture Credits:pharmaexcipients

Hard Gelatin Capsule

This is one of the types of gelatin capsules used for filling powder, granules, and pellets this is one of the capsules which is used by the automatic filling machine.

Hard Gelatin Capsule is mainly made up of gelatin which is a protein and they are very easy to fill with minor damage ratio during the filling.

Mostly 94% of hard capsules are used for the filling because of their low damage rate and ease to swallow.

Hard Gelatin capsules are very easy to store and very reliable to move from one place to another as they are made up of hard gelatin so they do not break easily.

Hard Gelatin capsule must be your first choice if you do not have any other priorities for filling using the automatic capsule filling machine.

HPMC Capsule

HPMC stands for HydorxyPropylMethyl these capsules are mainly composed of water and HPMC they are also used for filling using the Automatic Capsule filling machine.

At some level, they can be used for filling automatically but not that much like the hard gelatin capsules because these are softer than the hard gelatin.

They can be used for filling with an auto machine by removing the caps and after the filling, the machine will automatically join the parts.

These are vegetarian capsules that are used for mostly vegetarian filling material these capsules can help to grow the vegetarian market.

Soft Gelatin & Pullulan Capsule

Pullulan capsules contain the vegetarian stuff and they are water-soluble and made up with pullulan for the vegetarian stuff to be filled inside.

Pullulan capsule contains powder inside and it is one of the types of vegetarian capsules. These capsules contain vegetarian stuff.

The body of the pullulan capsules is made up of soft gelatin which makes them soft and easy to swallow but they can be broken down if used for automatic capsule filler.

Soft Gelatin capsules are used for filling liquid material so they can not be used by automatic capsule filling machines for filling because they contain liquid material and the soft gelatin will get damage if they are filled with an automatic capsule filling machine.

To keep the elasticity and shape of the soft gelatin capsules they need to be filled with some type of different machine.

Soft-gel capsule filling machine is being used for the filling of the soft gelatin capsules because there core purpose is to fill the liquid capsules.

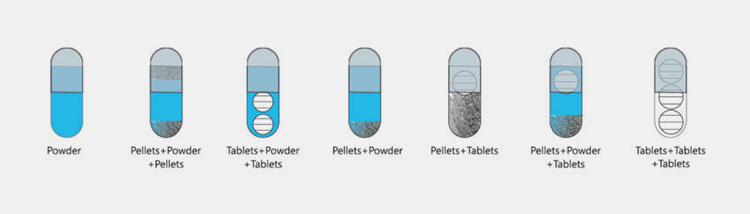

3.Which Material Can be used to Fill by the Automatic Capsule Filling Machine?

Pellets or Granules, powder can be filled with this machine.

Let’s get into the details.

Pellets

Pellets are in the form of small grains but very small in size as compared to sugar grains and other grains they are used for filling purposes.

Pellets can be used with other materials as well like you can fill a capsule with half of pellets and half of powder.

You can fill the capsules in different ways with two different materials or with all the quantities of the same type of filling material. Like Pellets of two different types or maybe one and you can also have them filled with powder and pellets.

Capsules filled by pellets

They are present in the form of spherical or semi-spherical shapes but small in size. They increase the flexibility of the capsules in designing and development.

Powder

The powder is one of the main filling materials used by automatic capsule filler powder-based capsule works slowly.

Powder mostly contains vitamins which help your body to grow the immune system it depends on the powder which type of material your powder contains and what do you want to fill the capsules.

Turmeric Powder Capsules

The powder can be filled in Hard gelatin capsule and pullulan capsules because these are the two types of capsules which hold the powder for filling.

The powder can be used along with pellets or you can use powder only for filling it depends on the filling requirements.

Capsules may contain powder and pellets at the same time. When you can not make a tablet with the drug it is more likely to make a powder of that drug and fill it inside the capsule as they are easy to swallow.

4.What Size of Capsules can Automatic Capsule Filling Machine Fill?

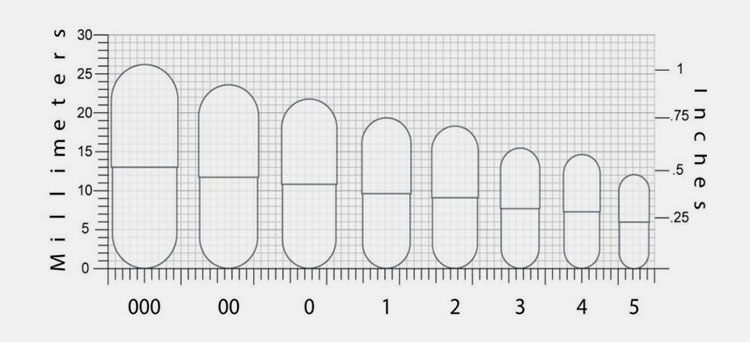

Different types of capsule sizes can be used for filling and they lie in between from 000 to 5.

- 000 Size

- 00 Size

- 1 Size

- 2 Size

- 3 Size

- 4 Size

- 5 Size

Different Type of Capsules-Picture Credits:Slideshare

You can choose the required size according to your production application.

The Powder density of the capsule can be divided into three further classes like the lightweight can hold up to 615mg of filling material, the moderate filling will be up to 960mg and heavy density can be up to 1370 mg with a single wall thickness of 0.112mm with the average weight of the capsule is 163.

This capsule can hold most filling material as compared to the other ones.

00 Size Capsule

They are smaller size capsules as compared to the 000 size capsules.

The filling weight density of this capsule in the light division is 430 mg, typical division 665mg, and the heavyweight density will be up to 950mg with a single wall thickness of 0.109mm and the average weight of this capsule is 118mg.

0 Size Capsule

The filling weight density of this capsule in the light division is 305 mg, typical division 475mg, and the heavyweight density will be up to 680mg with a single wall thickness of 0.107mm and the average weight of this capsule is 96mg.

The external diameter of this capsule lies between 7.34mm to 7.65mm.

1 Size Capsule

The filling weight density of this capsule in the light division is 225 mg, typical division 350mg, and the heavyweight density will be up to 500mg with a single wall thickness of 0.104mm and the average weight of this capsule is 76mg.

These are moderate size capsules. The external diameter of this capsule lies between 6.35mm to 6.63mm.

2 Size Capsule

The filling weight density of this capsule in the light division is 165 mg, typical division 260mg, and the heavyweight density will be up to 370mg with a single wall thickness of 0.102mm and the average weight of this capsule is 61mg.

The external diameter of this capsule lies between 6.07mm to 6.35mm. These are the most smaller size capsule lies in the moderate range.

3 Size Capsule

The filling weight density of this capsule in the light division is 135mg, typical division 210mg and the heavyweight density will be up to 300mg with a single wall thickness of 0.092mm and the average weight of this capsule is 48mg.

4 Size Capsule

The filling weight density of this capsule in the light division is 95mg, typical division 145mg, and the heavyweight density will be up to 210mg with a single wall thickness of 0.890mm and the average weight of this capsule is 38mg.

These are the smaller size capsule used for filling purposes.

5 Size Capsule

These are the smallest size capsule used for filling purposes these capsules can hold a very low quantity of filling material.

The filling weight density of this capsule in the light division is 60mg, typical division 90mg, and the heavyweight density will be up to 130mg with a single wall thickness of 0.089mm and the average weight of this capsule is 28mg.

It is always necessary to keep in mind the size of the capsule and which type of filling material you are going to use for filling.

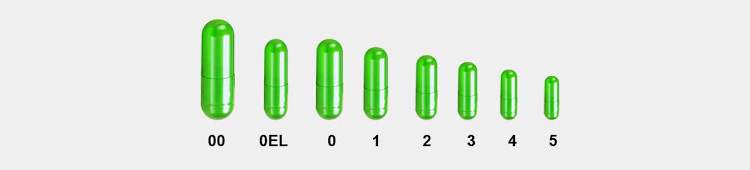

Various capsule sizes-Sources:capability

So you must know what you want and what design and type of material you are going to utilize for perfect production.

You can use either smaller or larger size capsules according to the requirements of your production.

5.What is the Filling Weight by Automatic Capsule Filling Machine?

The filling weightage is the complete load of the filling material that you have to fill into unfilled capsules.

The weightage of the capsules will be relying upon the thickness of the powder that you mean to fill in the unfilled available capsules.

A few powders are a lot denser than others along these lines expanding the all-out fill weight.

Aside from that, the fill weightage will likewise rely upon the powders finess.

6.Can you adjust the Weight of Powder Filled into the Capsule through the Automatic Filling Process?

The container fill weight is the all-out weight of the filling material that you need to fill into a vacant case.

The weight will rely upon the thickness of the powder that you mean to fill in the unfilled cases.

A few powders are a lot denser than others subsequently expanding the complete case or capsule fill weight.

Aside from that, the case filling weight will likewise rely upon the powder fineness.

Yes, you can make it happen by using the automatic capsule filling machine latest technology which makes sure that an adjusted amount of the powder goes into the capsule.

7.Can you Use an Automatic Capsule Filling Machine to make Liquid Filled Capsules?

No. It is not possible to fill the liquid capsule with the capsule filling machine. Because, automatic capsule filling machine is for powder and pellet, cannot used for liquid, if want for liquid, the machine needs to change the feeder and adding the band sealing machine.

8.How will you Benefit from an Automatic Capsule Filling Machine?

Full Automatic Capsule Filling Machine Advantages

AIPAK Full automatic capsule filling machine

To invest resources into a completely automatic capsule filler makes a few distinct advantages for any client and application.

The following are the best possible advantages related to utilizing completely automatic filling machines.

Higher Production rate

Most importantly, Automatic Capsule Filler permits clients to deliver more than could be created by manual epitome.

From pellets to powder, automatic filling machines permit different tablets or capsules to be loaded up with each process.

With a few mechanized rollers, the framework can arrive at rates of up to 91000 capsules for every hour, permitting a huge number of cases to be filled every day.

Dependability and Consistency

Capsules filling done by the hands can prompt fluctuation in the measure of filling material in every capsule.

While certain estimating gadgets and methods may assist with bringing down such fluctuations, utilizing such gadgets will likewise add time to the cycle.

Just other than speed, completely automatic capsules filler will take into account a repeatable, solid, and reliable filling with every cycle.

It is because the fill depends on a level, mass, weight, or another estimation.

Flexibility

Completely programmed encapsulators are not generally worked for one single application.

An automatic capsule filling machine can be set up to deal with a scope of fill materials just as the size and type of the capsules.

Likewise, numerous machines can deal with various items, with some ready to fill at least two unique sorts of fill material.

For organizations that produce numerous kinds of capsules, the adaptability of machines is perhaps your greatest advantage.

Basic Controls/Less Operator Interaction

Even though the automatic filling machine may appear to involve extensive set up from the start, nothing could be difficult at all.

Once in the process, the filling machine will regularly require basic changes to a great extent.

In any case, vital settings, for example, occupy times, ordering times, pumping rates, and more will be determined to a halfway found, touchscreen interface.

Also, whenever settings are adjusted for a capsule, administrators just need a review formula from the PLC and on all occasions the same recalling formula will be used.

Upgrade ability of the Machinery

At long last, the completely automatic filer machine may develop with you, does not matter if it is an organization or a private firm.

These machines can accompany pre-decided fill limits.

Yet, as your production requirements need increment, you can generally change the cut off (limits) to suit your present need.

In any case, on cut off points means limits, various machines may have various cutoff points.

The maximum velocity, for this situation, will rely upon elements, for example, size of capsule, and the material filled.

GMP Prerequisites Fulfilled

GMP (Good Manufacturing Practice) is a framework to ensure that your items are reliably delivered and controlled by the quality standards. And this GMP is intended to limit the dangers associated with any drug production that can't be killed through testing the eventual outcome.

Presently GMP consistency has been generally acknowledged as it is the most ideal approach to direct business that puts item quality first.

Machines have great similarity with the series of line machines

To ensure great quality capsules an automatic capsule filling machine is lined up with a series of machines, like capsule polishing machines.

- Vacuum Feeder

- Capsule Feeder

- Metal Detector

- Industrial Cleaner

The whole machine does have to cooperate together to run it very well. Not even a single step can be skipped within the automatic capsule filling machine.

Different Capsule Sizes

All Auto capsule filling machines are planned with different filling sizes,from #00,#0,#1,#2,#3,#4,#5 to all well-being size cases.

Besides, auto capsule filling machines can fill all different capsules with different weights, from 5mg to 20mg, which will meet with some miniature dosing or measurements needed to severely control assembling.

In other words, you will just have to change the filling determination on the machine or change the shape for your distinctive case sizes or weight filling and the programmed container filling machine will be your acceptable decision for your measurement controlling or miniature dose productivity

Other available advantages include;

- Efficient use of materials

- Improved safety

- Reduced factory lead times

- Better capsule quality

9.How many types of Automatic Capsule Filling Machine are there in the market now?

Automatic capsule filling machine can be sorted into two types:

Fully automatic capsule filling machine

Semi automatic capsule filling machine

Fully Automatic capsule filling machine

Fully automatic Capsule Filler has the limit of topping off 90000 containers/hour for various variations of the powder plan.

AIPAK NJP-2500 Fully Automatic capsule filling machine

By using the automatic filler you have the ability of filling the capsule with more accurateness.

With the latest inventions in the automatic models, this machine gives the possibility of filling different sizes capsules.

The fill material can be

- Granules

- Powder

- Pellets

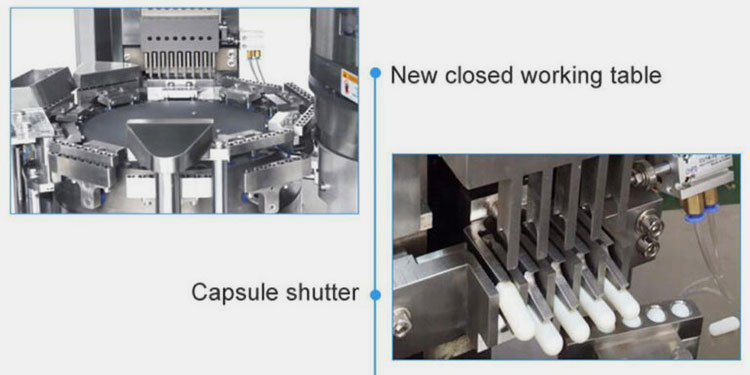

Consequently, capsule filling machine includes an encased dosing framework that helps in diminishing clean recurrence through residue attractions.

Semi Automatic Capsule Filling Machine

AIPAK Semi Automatic Capsule Filling Machine

The semi-automatic capsule filling machine is favored for applications that require exact assembling strategies for current drug methodology.

The Semi-auto capsule filling machine considers a more significant level of mechanization when contrasted with the manual container filling machine, consequently guaranteeing a more elevated level of filling weight exactness.

This capsule filling machine is considered able for the activity of case filling of fluctuating sizes with powders, granules, or pellets.

With the GMP guidelines producing techniques utilized for self-loader case filling machine, it accompanies an all Stainless-Steel covering.

The machine is equipped for yielding high yields, for example, 25000 to 47000 cases/hour that relies upon the size of the case and the administrator's range of abilities.

It plays out the activity of on line cleaning and arranging. Cleaning of the tablets don't need administrators and there is no requirement for a different stockpiling for the filled container.

The semi-auto capsule filler machine has a four-speed drill that permits it to work and fill various sorts of powder and pellets.

The filling table of the machine has a variable speed that guides in accomplishing high measurements exactness.

Semi-automatic capsule filling machine joins programmed case stacking framework to guarantee quicker, more secure, conclusion, and launch of filled cases.

It additionally has an auto drug container in-feed system to dispose of any variety in weight and in this manner guarantees high efficiency.

10.Is there any Disadvantage of Automatic Capsule Filling Machine?

The fundamental disadvantage of a completely automatic filling machine is the high capital requirements for the purpose of the investment in the beginning.

It's just plain obvious, automatic is costly.

AIPAK NJP-800 Automatic capsule filling machine

Expensive Investment

You'll require a huge number of dollars to configuration, manufacture, lastly introduce automatic hardware like the automatic capsule filling machine.

That isn't the place where it closes.

Large Space

Another disadvantage of this machine is more space is demanded. Normally, this machine require space as compared to the usual ones.

In other words, more premises is required for placing this machine.

11.What is the Difference between Fully Automatic Capsule Filling Machine and Semi Automatic Capsule Filling Machine?

| Automatic Capsule Filling Machine | Semi Automatic Capsule Filling Machine |

|

|

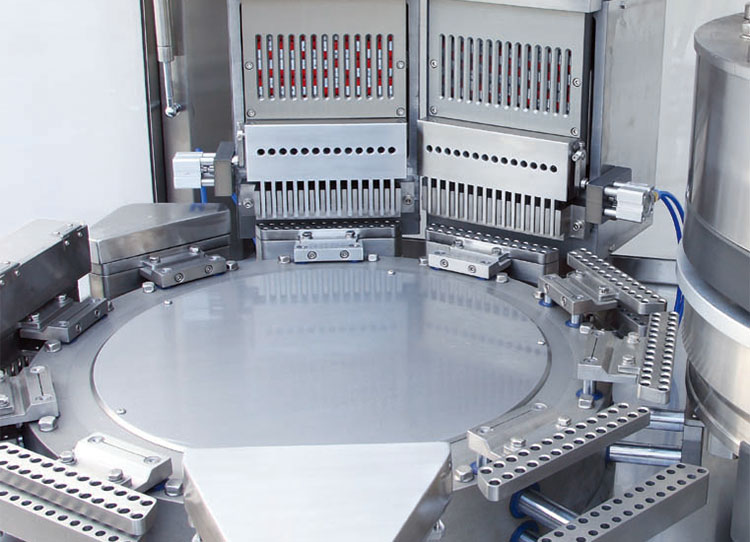

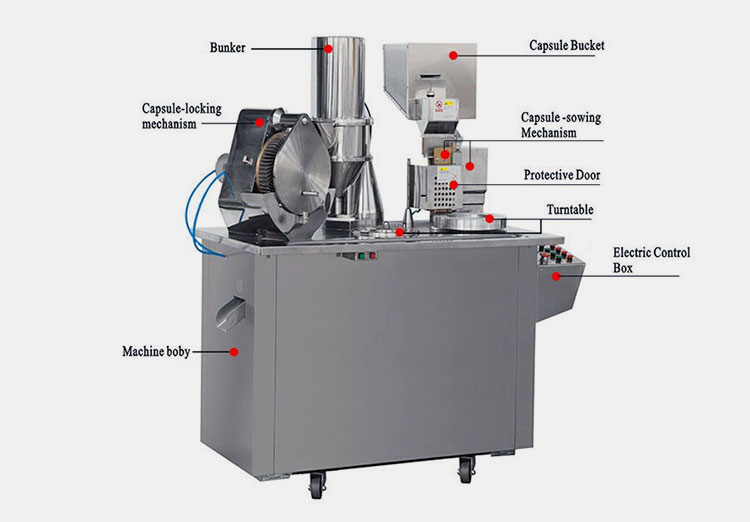

12.What are the Main Components of Fully Automatic Capsule Filling Machine?

AIPAK Full Automatic Capsule Filling Machine Main Parts

Here you will be explained about the components of the automatic capsule filling machine and how they support the machine.

Presently, we realize that the capsule filling machine may come in different kinds, including various types the shapes and sizes as well.

This means a few machines may accompany more parts when compared with the others.

Furthermore, a portion of these parts is the equivalent across all capsule fillers while some are explicit to a kind and additional model.

It is a mechanical unit together containing various parts which are called Capsule Filling Machines.

According to the parts of the machine, you may note that it may be placed into three classes; water-driven, mechanical, and additionally electrical parts.

The other thing about the classification likewise is either fixed or moving.

Luckily or tragically, we can't examine these parts here because they are too much to share in this article.

So for the extent of this guide, I will center around the primary parts name and elements of the various sorts of capsule filling machine.

Yet, before we get to that, here's a picture to show you the specific situation of these parts.

Kindly note that this picture is explicit to the auto encapsulate.

Even though, a large portion of these parts is comparably situated across the same line in a capsule filling machine.

As should be obvious, how many parts and configurations will rely upon the model of the capsule filler machine.

Material Hopper / Items Hopper

The item/medication container is made up of a tempered steel compartment that holds into the material you would like to have.

In the picture above, the container is the highest of the machine.

For certain machines, it would seem that this:

Ordinarily, the plan of the material container is with the end goal that it permits material to course through effectively into the pump portion of the machine.

So its plan frequently differs from the producer and machines model.

Generally, however, planners go for the shape of the hopper with inclining sides towards the pump of the machine, similar to a cone.

Something else, typified materials are intended for human utilization.

This means, there is consistently a need to protect anything.

Thus, you will see that most hoppers in the machine have a cover with a handle to save any passage of unfamiliar material.

Material Pump

The capacity of the pump just is to intake material from the container and power it into the infusion wedge.

A decent case filler will likewise have a return line to divert extra material back to the container.

How you position your pump in the capsule filling machine plays a very vital role.

It should resemble the picture above to take into account the simple getting of materials from the container.

Infusion Wedge / Infusion Wedge

Presently, the fundamental capacity of the infusion wedge is to warm the fill material to such a level that it reaches the appropriate temperature.

It is done while infusing the fill material as it keeps on rolling to the pass on the hole of the two rollers.

Actually, it is the pressure of the pump that empowers the material to course through the wedge consistently.

Comprehend that the plan of this part frequently differs, contingent upon the kind of machine and model.

Infusion wedge for auto capsule fillers, for example, may accompany sensors to help organize the movement.

Some additionally accompany shut off valves while others can go all over.

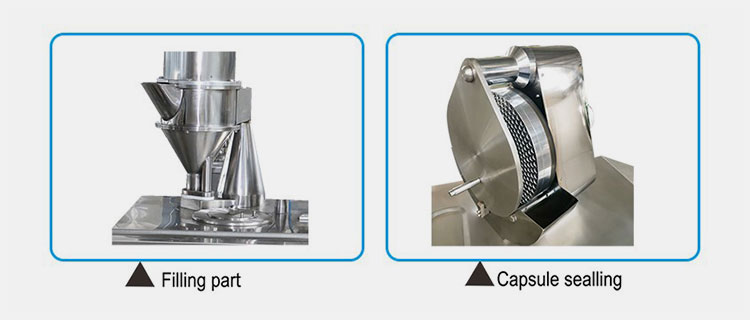

Container Filling Mechanism

The capsule filling component is liable for cycles of filling material into cases.

It comprises a measurement filling gadget that conveys exact amounts of material into unfilled capsules.

The framework likewise comprises a level sensor that permits it to deliver or cut the inventory of more material during filling.

A notable thing here is, a level sensor is just accessible for completely auto machines.

By and large, the automatic capsule filling framework guarantees exact and accurate embodiment measures.

It might highlight at least one filling gadget relying upon the sort and model.

Tooling System

The tooling framework is the core of a capsule filler.

It comprises two-pass on rollers that keep on turning at a consistent speed.

The framework likewise comprises an automatic capsule filling machine plate just as a turret.

Other than this, there is that turntable that keeps dust away from getting into the machine’s pieces of the machine.

Note that the turntable regularly relies upon the file development of the machine for exact revolution.

There is likewise a dosing and release framework. These assist to protect any conceivable vortex when containers leave the moving framework.

The dosing and release are one of the tooling framework's segments that are anything but difficult to disassemble and assemble.

Presently, the whole tooling framework configuration additionally differs relying upon the sort of machine.

Plan, in such manner, additionally will in general rely on the filling mix the machine usages.

Filling mix, kindly note, alludes to the sort of material documented.

It may very well be pellets and powder, tablets, or granules.

Main Body of Machine

The body is the main portion of a Capsule Filler as it decides the whole structure's soundness and solidness.

It essentially is the part that keeps everything held (parts and segments) together.

Normally, the primary body Capsule Filling Machine is made of hardened steel.

Why treated steel?

To ensure steadiness, solidness, and protection from wear and tear properties, for example, effect and erosion.

Note that the body shields any remaining inward segments from harm and unapproved access.

Greasing up System

A completely automatic capsule filler or capsule filling machine regularly has a few moving parts.

This means you need to guarantee that everything is on the track related to their maintenance to stay away from the tearing of the machine.

Oil is a basic thing for the maintenance of the machine.

It will help decrease harm just as guarantee clean launch.

Remember that the greasing up framework will in general consequently grease up packing and dosing circles to guarantee a productive fitting launch.

This assists with diminishing grinding in sliding segments, as a result of that guaranteeing smooth activity.

In general, in auto capsule fillers, a layer of oil greases up the strip both during fixing and filling measures.

Progressed models even accompany fine channels.

Well known oils that you can utilize incorporate edible mineral oil.

Magnesium stearate, Coconut oil, and glycol oil.

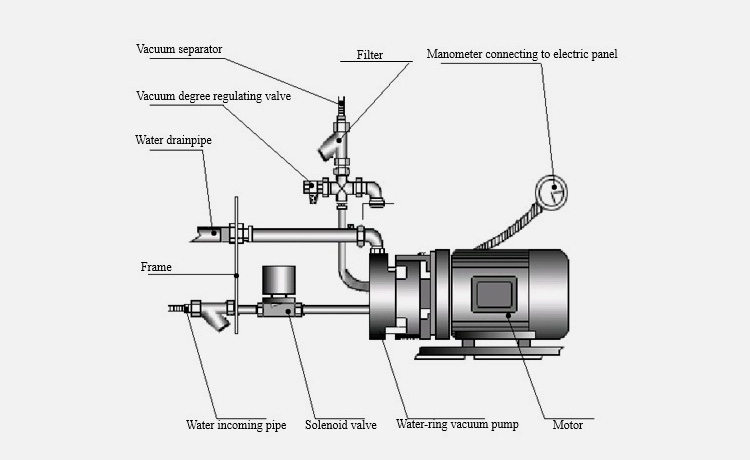

Vacuum System

Despite the sort and model of your auto capsule and tablet filling machine, a vacuum framework is essential.

To begin with, the vacuum loader associates the container stacking gadget with the hopper and the material stacking port to the hopper.

Secondly, the vacuum framework isolates the unfilled case to stay away from harm.

Progressed programmed machines accompany a self cleaning station.

This tidies up the machine in everything cycle.

Also, a few models get items utilizing a vacuum framework instrument.

Basically, a vacuum framework is indispensable in the working cycle of an auto-filling machine.

Control System

Automatic capsule filling machines, just as certain models of self-loader case fillers, utilizes the panel control framework to control tasks.

Normally, SIEMENS panel control is utilized to guarantee solid machine activity.

Additionally, these machines come completely introduced with an overly inviting human-machine interface (HMI) as a touch screen.

The Panel control and touchscreen together all structure part of the control arrangement of these case filling machines.

Other control components that you should know incorporate;

Miniature electric flow control that shields the machine from over-burden.

Crisis stop and vacuum checks for case division.

Insight form control

The above is, anyway more normal is completely auto capsule filling machines.

Keep in mind, you don't have to get a completely computerized framework in the case you don’t want to do this element is discretionary.

You can decide on a self-loader machine with the exception of the completely mechanized control board.

Of parts names and capacities, this is all you require to know with respect to programmed fillers.

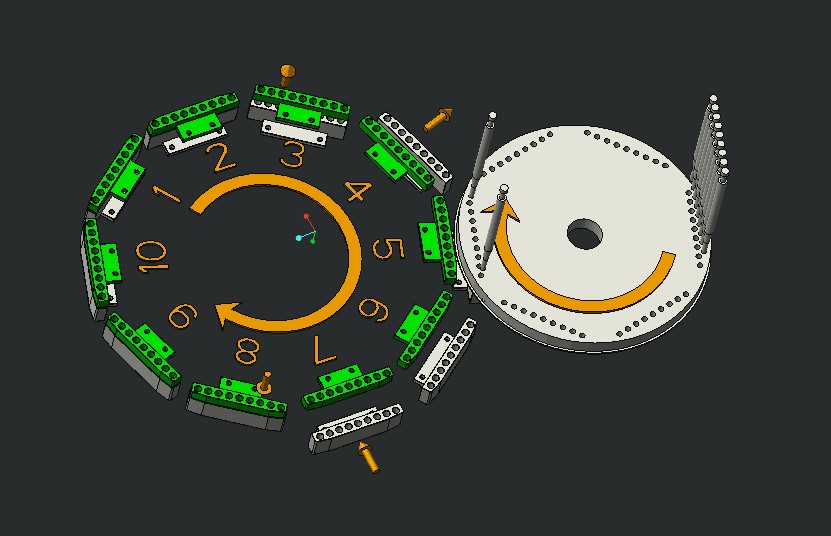

13.How does Fully Automatic Capsule Filling Machine Work?

Full Automatic Capsule Filling Process

So we should rapidly experience its working standard.

What's more, as we do this, comprehend that filling of the capsules in this machine occurs in four phases which are;

- Hard capsule seperating

- Fill material making process

- Encapsulation phase

- Rejection of capsules

- Locking and Discharge

Top to bottom, this is the way the whole cycle happens;

Phase 1: Hard capsule separating

The first stage of working is the separation of the capsules and done even before starting the process. The top and bottom is separated at the first place and then anything else is being done.

Phase 2: Filling Material Making Process

Everything in this phase takes place in the hopper of the machine in the material container.

So first, you will set up your material relying upon the substance you need your hard gel capsules to comprise.

Depending on the production requirement material can be oil-based or paste-based.

What's more, contingent upon the idea of the material, you may require extra gear, for example, loading device and so on.

Whenever you are making the ideal filling material, you can put it on the hopper of the machine, from where it will stream to the infusion wedge framework.

Phase 3: Encapsulation Phase

The encapsulation is the most vital phase in the working rule of the capsule filling process.

Here, the machine brings both the gelatin and fill material together.

Encapsulation of the hard gel machine has two strips moving into the roller framework.

The strips move in rotating movement as the machine simultaneously manages the fill material within the gelatin strips inside the rolls.

When filled, the gelatin wraps the filling material bringing about a specially designed capsule for customized reasons.

The shape and the size of the capsule will be relying upon the type of cavity you make while using the blister packing machine.

At that point, the release chute or discharge chute system will be used for the purpose of placing capsules in the next phase.

As this occurs, the brush inside the chute will eliminate anything that may have stuck on the bite the dust rolls.

The stripper rollers (still inside the moving framework) will likewise eliminate any stuck capsules on the gelatin web.

Phase 4: Rejection of capsule

Machine rejects the capsules which are not filled well of something out of the shape (If they won’t be closed very well).

Phase 5: Locking and Discharge

In this stage of the filling lower and upper part of the capsules are closed. The product is then released and discharge at a place to be collected.

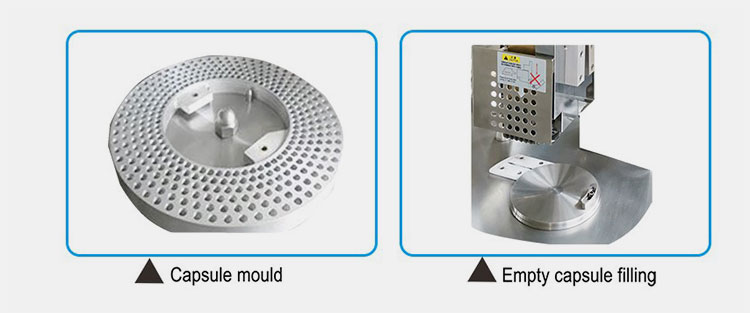

14.What are the Main components of the Semi Automatic Capsule Filling Machine?

These are the parts of the semi auto machine some of them are the same as the auto one.

Semi Automatic Capsule Filler Machine Parts

A) Material Hopper

It is already mentioned above and it is the same as an automatic capsule filling machine.

B) Machine Body

It is already mentioned above and it is the same as an automatic capsule filling machine.

C) PLC/HMI Interface

Most of the time a semi-auto machine has a PLC segment with touch screen HMI.

This permits clients to enter different boundaries for filing of the capsules.

The plan and design of this part will rely upon the sort of semi-auto capsule filling machine that you are using.

D) Powder/Pellets Filling System

This part fills powder and pellets in the vacant cases.

Ordinarily, it handles the machine's ability to fill.

E) Loading Uploading System

The stacking framework is an incorporated framework that starts the stacking cycle of capsules.

It guarantees the capsules are appropriately placed and powder fills properly.

F) Pneumatic/ Compression Systems

It gives an instrument that assists with pushing filler material in the vacant capsules by using the air compression system.

G) Electrical System

It supplies the capacity to the whole machine making the filling method simple and productive.

H) Capsules Filling Station

It is the place where the dosing happens.

Much of the time, the speed fluctuates boundlessly relying upon the design of the machine.

I) Capsules Tray

The plate comes in two sections that make it simpler to isolate two containers prepared for the filling cycle.

j) Rectifier

It positions items prepared for the filling cycle.

k) Capsule Opening and Closing System

It is a part that shapes the stacking ring and joiner chute.

Through this part, you can open and close the containers quickly and productively.

15.What is the Working Principle of Semi Automatic Capsule Filling Machine?

Before you begin utilizing your semi-auto machine for filling capsules, test it first to guarantee it is in an accurate working phase.

For doing this, you need to experience the process once or at least, need to be aware of the process and their names.

Information on the catches on the control board is likewise fundamental to legitimate testing of the machine.

Check all the parts are perfectly fitting in and now turn on the machine.

1- To begin, turn on the pump and the air pack.

Ensure that the turning bearing is steady with the course of the bolt.

2- Next, turn the handle R to the lower position, and afterward, turn on the container stacking engine.

3- Press ON and pivot the Knob R to make the case stacking component accelerate step by step.

Force catch and control board

Force On and control board

4- When it arrives at maximum velocity, put empty void capsules into the container, run a test on the stacking at low speed and steadily accelerate.

You can change the running pace to match the quality of the capsules.

5- This is a quick speed for the good quality capsule and moderately low speed for inferior quality cases.

6- Presently put the lower shape to the turntable and add the filling to the hopper of the machine.

Just like that, start filling capsules but just turning the machine on.

7- When all containers are being filled, cover the hold mold with the upper shape and take them to the station where it is locked.

Now, turn the locking cover the other way, and take the capsules out squeezing the foot pedal or bolting button.

Here's is a synopsis of the working guideline for these sorts of capsule filling;

1- Situated under the rectifier, an empty capsule comes here.

2- It at that point isolates the covers from the bodies by pulling the vacuum from underneath the ring.

3- The body of the empty capsules comes under the hopper to begin the process.

4- Whenever this is done, the cap and body ring rejoin and reposition before pins that push the bodies to bolt.

5- From that point onward, the plate is swung aside, and with the guide of the pins, the shut capsules are shot out from the machines.

That is it! The whole activity cycle of semi-auto capsule filler.

16.What are the Technical Specifications of Automatic Capsule Filling Machine you can refer to?

Technical Specification

| Model | NPJ-1000 | NPJ-1200 |

| Productivity | 6000 capsule/H | 7200 capsule/H |

| Size of Capsule | Capsules Size 00"-5" and safety capsule A-E | Capsules Size 00"-5" and safety capsule A-E |

| Total Power | 9.5 kilo watt | 9.5 kilo watt |

| Water Supply | 500L/H,0.2-0.10Mpa | 500L/H,0.2-0.10Mpa |

| Dust Collector | 160m³/H | 160m³/H |

| Size | 1020x860x1970MM | 1020x860x1970MM |

| Weight | 900KGS | 900KGS |

17.Can you put capsules that are already split into Automatic Capsule Filling Machine?

No. You need to utilize capsules that come in one portion. The vital thing to know is that you can't reuse the capsule by using this machine. Even if the capsule isn't filled the possibility of the usage is only once.

The resistance of the capsules is tiny whenever they have experienced the machine the opportunity of them stucking out or causing a jam is more.

18.How many Operators do you need to Operate the Automatic Capsule Filling Machine?

Actually, with the automation the need of the people would be decreased however, even with the fully automatic capsule counting machine you sometimes need to have one or two person maximum to keep the process going.

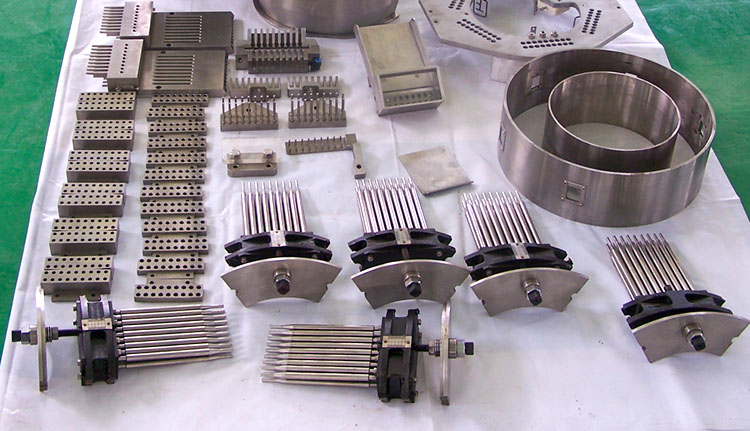

19.Do you need to Change Tooling for filling Different Materials by the Automatic Capsule Filling Machine?

No.You don’t need to change the tooling system.

Fortunately, the change of the tooling in the automatic capsule filling machine is not required as per the change of the material.

Only for that reason dosing disc affect is used in that type of the machine.

It is fit for controlling the tooling framework to create filling materials of various weight and amount.

20.What are the Safety Features of an Automatic Capsule Filling Machine?

Below defined are some of the major safety feature of the automatic capsule filling machine.

Automatic Cleaning Process

There is a cleaning system in the Automatic Capsule Filling Machine. You just have to click on the button and the machine will begin the Automatic cleaning process.

In the first phase, water comes in contact with the part that is continuously in contact with the product and cleans the dust from that part of the Automatic Capsule Filling Machine.

In the first phase, the part is cleaned but some dust is left on that part. In the second phase, you have to manually clean the processing area of the Automatic Capsule Filling Machine so that no dust or residue is left behind.

Shock Proof

Automatic Capsule Filling Machines consist of many different parts. It includes motors and many electrical parts.

This machine has many precautions to save human life from injuries. It includes saving a life from possible electrical stun.

If there is any possibility of the electric stun, there is an alarm system that starts to beep to save any human life in danger.

Every electrical part of the Automatic Capsule Filling Machine is fully encased and You cannot use this part of the machine when the machine is on.

You have to turn off the machine if you want to use that part of the machine. If you try to open the sealed door without turning off the machine it will turn off automatically.

Capsules filled with different material

Modern Technologies

Automatic Capsule Filling Machines use polycarbonate solid sheets to lock up the station. The doors of the compartment have interlocking technology so you cannot open the machine when it is on.

There is also a door sensor on every compartment of the machine if you try to open the door of the machine it will turn off automatically.

If you have an emergency during the process, there is an emergency button in the machine. If you press the emergency button every process will stop immediately and the machine will turn off.

There is an alarm system in this machine if the quantity of capsule or powder is low then the alarm will turn on automatically.

Enhanced Data Security

As organization security of the information is the most important aspect. you need this information to start the production of the product.

In the Automatic Capsule Filling Machine, the data is in the computerized format so there is no chance of the error. In this machine, there is also the option of printing or storing the data in this machine.

Automatic Lubrication System

There are many moving parts in the Automatic Capsule Filling Machine. There are many moving pistons in this machine.

you will have to lubricate these pistons and the other moving parts.

There is an automatic lubrication system in this machine you have to click on the control panel of the screen and this machine will lubricate the discs and pistons automatically and it will reduce the friction of the components.

It ensures the clean ejection of the piston and it will expand the life of the machine.

21.What Quality Standards Should Automatic Capsule Filling Machine Conform to?

At whatever point you are buying an Automatic Capsule Filling Machine you need to ensure that it must have these Standards.

Current Good manufacturing practices (cGMP) quality Standards

ISO certification quality standards

CE quality standards

Current Good manufacturing practices (cGMP) quality Standards

Current Good Manufacturing Practice (cGMP) is a standard to ensure that your items are reliably created and controlled by quality principles.

Furthermore, this quality standard is intended to limit the dangers of engaging with any drug creation that can't be wiped out through testing the end result. Presently cGMP quality standard has been generally acknowledged as it is the most ideal approach to direct business that puts item quality first.

ISO certification quality standards

ISO ensures that an organization system, documentation method, or creating measure has all that is needed for standardization and quality affirmation ISO represents the International Organization for Standardization is general collusion of public rules bodies.

It is a non-legislative affiliation that includes standards bodies from more than 160 countries, with the body of one rule addressing each part country. The American National Standards Institute.

CE quality standards

CE represents Chartered Engineers. The CE mark on a thing exhibits that the creator or transporter of that thing states its consistency with the critical EU sanctioning and the thing may be sold wherever in the European Economic Area.

It is a criminal to secure a CE engraving to a thing that isn't pleasant or offer it accessible to be bought. CE mark on the item ensures that the item is as indicated by the EU standard of security and wellbeing insurance.

22.What are the Supporting Equipment for Automatic Capsule Filling Machines?

Supporting Equipment for Automatic Capsule Filling Machines

Whenever you are making anything you have to use different equipment other than just a machine so in the automatic capsule filling cycle you will require the help of other gear.

Here is the fundamental help hardware that you can use in the filling of various kinds of capsules.

Equipment that you must have before the Capsule Filling Process.

These are the equipment that you will require before

High Shear Granulator Machine

A high-shear granulator comprises a tube-shaped blending bowl, a three-bladed impeller, a chopper, a helper chopper, an engine to drive the cutting edges, and a release pot. It is a shaping cycle for granulation that has been improved for application in the drug business.

It is a machine which is used to crush the stuff into the small pieces with the hammer which hit the material again and again.

It is used to separate the material according to their sizes. It is newly used equipment in the drugs industry.

Fluid Bed Processor

A fluid bed processor is used for the covering and the mixing of the product in the drugs industry.

Here is the equipment that you must have after Capsule Filling in Automatic Capsule Filling Machine.

These are the equipment that you will require afterwards.

Capsule Drying System

Drying system is used to dry the product after the filling of the capsules.

This sorting machine is used to separate the capsules according to their sizes. This machine sort out capsules with the same size.

It is used to clear any residue left on the capsules. It is an exceptional type of machine in the drug industry.

Blister Packing Machine is a unique machine in the drug industry it is used for the packing of capsules in the Automatic Capsule Filling Machine.

23.How to choose the Most Suitable Automatic Capsule Filling Machine?

Most of the pharmaceutical industries use Automatic Capsule filling machines for more production and an accurate amount of filling in capsules.

If you are going to buy an Automatic Capsule filling machine you just need to know that it must have the features which you are needed.

There are some of the main features which I am going to tell you about Automatic Capsule filling machine which you need to keep in mind while purchasing one.

AIPAK NJP-400 Automatic Capsule filling machine

Capsule Size and Type

Before buying the machine you must decide which type of capsules you are going to use and what will be the size of your capsules.

Joint capsules are used in Automatic Capsule filling machines as they are cheaper to buy and mainly used in automatic machines.

Capsule Filling Material

Some of the machines used to fill the liquid inside the capsules while some others use pellets and powder as a filling material so you must buy one according to your filling needs.

Different filling materials

Capsule Filling Ability

Whenever you are going to buy the Automatic Capsule filling machine see what type of filling material can be used or what type of material is this machine is capable of to put in the capsules.

Like, some of the machines used for powder filling, and some others used for pellets and mixture.

Automation

An automatic Capsule filling machine must have all three features.

- Capsule Separation

- Capsule Filling

- Capsule Locking

Size of machine

You must buy a moderate size Automatic Capsule filling machine or you can buy one according to your production plant.

The greater the size more labor you will be required to operate the machine always choose small with more production rate.

Investment on Machine

Always decide how much you are going to pay for the machine itself because there is some other equipment required to buy along with the machine.

Select the machine which has all the features in itself as per your plan to buy with no further investment.

Production Rate

Your machine must be capable of filling from 1k to 1200 capsules per minute as it is considered the best output by any machine.

In less time you will be able to get more production with this type of mechanism.

Warranty & Brand

It is one of the main features when you are going to buy an Automatic Capsule Filling machine because it is not a small amount of money that you are going to invest in a machine.

Buy a machine from a good brand by reading the reviews and feedback from the customers.

You might face some problems after some time if the product is not good and not fulfilling your needs so it will be good for you to buy one with a good warranty time.

Lastly, you need to know the dimensions as well so, you can adjust this machine better at your premises.

24.What is the cost of Purchasing an Automatic Capsule Filling Machine?

Automatic Capsule filling Machine lies in three different categories according to the work rate and size.

AIPAK Small Automatic Capsule Filling Machine

This machine is used for small-scale purposes like you can use it in a Hospital for your personal use with limited production or in a Medical store.

Medium Scale Automatic Capsule Filling Machine

If your want to extend your production rate to deliver your products to other pharmacists then

this mid-range Capsule Filling Machine is the best choice for you to buy.

AIPAK Medium scale automatic capsule filling machine

Large Scale Fully Automatic Capsule Filling Machine

This machine is used for Industrial purposes when you want to increase the production rate in less time frame then this Machine is the best to buy.

AIPAK Large scale automatic capsule filling machine

25.How to Troubleshoot Common Problems of Automatic Capsule Filling Machine?

Some common problems may occur during the Capsule filling that you must know and ready to find their remedies.

1- Capsule not Entering the filling place

This type of error/problem can be occurred due to some technical issues in the Machine.

- There is a small part in the machine called the Baffle plate which maybe not be set properly after pulling out the capsules.

- The filling place of the machine may be damaged.

- The slow speed of the machine can also cause a problem.

- Maybe some dust particles or other foreign particles are inside the magazine.

Solution

Set the Baffle plate properly so the flow of the capsules can not be stopped and the magazine can load them properly.

Before starting the Capsule filling see if the magazine is damaged then replace it.Because the damaged magazine will affect the smoothness.

In the ideal state, machines are used at high speed when the speed is below 50-60spm while in general use then this problem may appear. Try to use the machine at high speed.

If there are some other particles present in the magazine use compressed air pressure to remove them.

2- Capsule getting Damage

During the filling, the capsule may get damage this happened because the rectifier block is not aligned properly.

Rectifier alignment with body bushes or cap bushes can cause this type of problem.

Damaged capsule

Solution

The solution is easy to do check the rectifier is aligned perfectly and remain in touch with the cap bush if not try to align them properly.

3- Loss of Cap during Transfer

This problem can occur due to two reasons during the capsule filling process.

- High vacuum inside the machine.

- Miss Alignment of cap and body bush.

Cap and Body of a A capsule-Picture credits:Sagar Kishor

Solution

High vacuum power sometimes can cause the loss of cap in capsule filling to try to use the moderate value of vacuum with the help of throttle.

Before capsule filling check the alignment visually between cap and body bush. Do this by using the given alignment gauge.

4- Capsule not Separating

Here, are some problems that can work against the separation of capsules.

- Leakage through the Filters

- Worn out bushes

- Loss in the Spring extension

Solution

If the vacuum is decreasing slowly there will be some leakage in the filters of the vacuum. Try to remove the vacuum or replace it.

When the capsules get stuck in the bushes try to clean the bushes and if the cleaning does not work then try to remove the specific bushes.

Poor spring extension on the top slider will defect the separation try to replace those poor spring extensions.

5- Weight of Capsule not achieved as per your need

- Size of the capsule smaller/larger

- Binding is not appropriate

- Poor flow of filling product

Solution

Always check the variations and parameters of the capsule that how much it can hold inside with which intensity.

What type of capsule you are using for what type of filling material like, powder, pellets, or liquid.

Form the slug properly to get the precise quantity of filling product before the binding is done. If the slug is not formed perfectly some of the material will lose and will affect the weight of the capsule.

Check the flow of product according to the filling speed of the machine or the filling product is coming in the desired quantity and see the output is good or not. If not try to adjust the flow of filling product.

6- Disturbed Weight Variations

Three major variations can cause this type of problem in capsule filling.

- The gap between dosing disc and wiper block.

- The maintenance level of body bush and tamping pin.

- The gap between the dosing disc and supporting pad.

- The maintenance level of body bush and dosing disc.

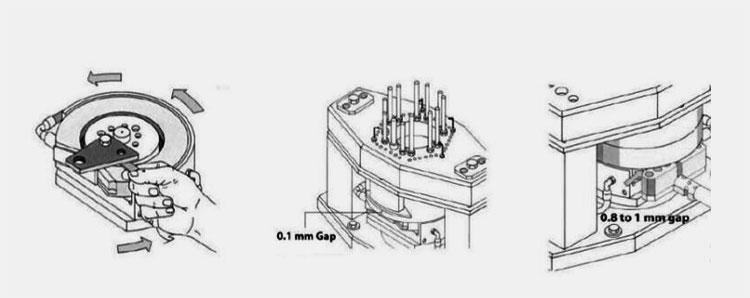

Gap and maintenance level between different parts of the machine-Picture credits:bushan gike

Solution

The gap between the dosing disc and wiper block is measured in NMT and this gap must be 0.1 mm.

The body bush must be maintained from 0.2 mm to 0.4 mm.

The gap between the dosing disc and the supporting pad is measured in NMT and this gap must be 0.1 mm.

Dosing disc and the body bush must be maintained from 0.8 mm to 1.0 mm.

26.How to Maintain Automatic Capsule Filling Machine?

You know that maintenance of the machine is necessary to keep things going well so it is recommended that you must utilize some energy to clean up the machine.

Keep in mind never do any kind of cleaning when the machine is in its active state or connected to the main power supply doing this can cause some major damage.

Cleaning

Cleaning is a very important factor that can affect your production rate of an automatic capsule filling machine.

Every pharmaceutical industry will recommend you to clean your machine on regular basis because cleaning will help your machine to work properly and smoothly.

When you are done working with the machine or you are going to change the filling material of the machine then it is necessary to clean all the parts including the suction head, lower assembly, and upper assembly.

In general, you must clean all the outer parts of the machine which are in contact with your filling material.

Lubricant addition/Oiling

Try to give proper grease to all the moving parts of the machine which are working under the table of the machine.

All the parts which are doing the transmission work must be stain-free usually this is done with all the mechanical parts of the machine like the motor, feeding cam, scale disk, jointing capsule cam, a rolling bearing, and filling mechanism cam.

Always use the recommended lubricants from the manufacturers for best results.

There are some following steps to do the lubrication/oiling.

- Lithium grease or lithium base grease is best for coating all the cam surface areas inside of the machine.

- Do the lithium base grease lubrication after every 200hrs of work.

- Machine oil must be used for all the joints which are working to move the different parts of the machine.

- This process will be done after 2 days of work.

- After a weak or 10 days check the amount of oil or oil level.

- Replace the lubricant oil after 3 or 4 months.

- It is precautionary to check the lubricant oil level after every month.

Safety of the Clutch

This part of the machine ensures the safety of the machine and maintains the load of the machine to its idle state.

Clutch ensures that your machine is working in its normal position when the load is more than the normal value then the safety clutch will slip and the machine will not work properly.

Try not to overload the machine.

By tightening the round net of the clutch this can be done and the machine will work back into its normal form.

Conclusion

As you know cleaning and lubrication are done to almost every machine but during the cleaning of the Automatic capsule filling machine, you must have proper knowledge about all the machine parts.

here are so many key components inside the machine which may get damage if you don’t have any knowledge about these parts that how you can open and then do the further work.

Always use the instructions according to the given manual.

27.How often should the Automatic Capsule Filling Machine Tooling be Cleaned?

Cleaning is as important as the machine itself because by doing the cleaning one can make sure the safety of the product and quality output.

Filling Material Change

It is considered to be necessary to clean the machine on regular basis or when you are going to change the filling product.

All the parts which remain in contact with the powder or other filling product must be cleaned regularly to make your machine stain-free.

By using a piece of cloth or condensed air pressure you can do the cleaning.

Grease Stains Cleaning

Grease stains can do damage to the technical parts of the machine like a motor, filling mechanism cam, a rolling bearing, and a scale disk.

So you need to clean the machine after 500 hours. This cleaning must be done to all the mechanical parts of the automatic capsule filling machine.

Vacuum System Cleaning

As you know this machine also works through the vacuum system so it is necessary to keep the vacuum system clean so the air pressure remains the same for the flow of the machine.

You need to clean the vacuum system of the machine after 200 hours so that the vacuum system does not get any minor problems and the production rate must remain the same.

Vacum System of Automatic Capsule Filling Machine-Picture credits:ipharmachine

Some other major impacts

There are some other things that you must keep in mind along with the cleaning

- All the surfaces of the cam must be coated after 50 hours of working and this must be done with lithium grease or lithium base grease.

- The oil level of the machine must remain as required keep on checking the oil level after 250 hours of working.

- The driving chain must be checked and lubricate after 50 hours of working this must be done with lithium grease.

- All the joints along with other moving parts of the automatic capsule filling machine must be lubricated with the machine oil after 50 hours of working.

- You must be done the lubrication oil change after 3000 hours.

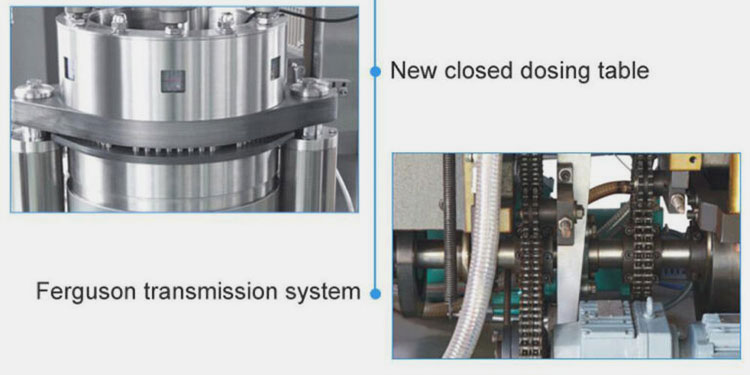

28.Are there Any New Technologies of Automatic Capsule Filling Machine?

Yes, there are new innovations and technologies in the capsule filling industry.

The majority of the advancements center around expanding the security of the machine and client, just as the profitability.

The new innovations of the automatic capsule filling machine help in improving productivity, performance and Efficiency.

A portion of the new developments and advancements that improve execution, profitability, and proficiency is below;

- Shaded touchscreen human-machine interaction board that takes into consideration simple control of the framework and production management.

- The machines essentially have a PLC framework that will support the production level.

- Encased dosing, moving, and electrical framework for the steady and productive cycle.

- For quick and simple cleaning measure usages of the cleaning system that uses vacuum.

- Auto greasing framework that applies enough grease on the moving parts to protect any kind of destruction.

- This will likewise expand the administration life length of the capsule filling machine.

- Variable recurrence drive framework for simple control of speed of engine and the machine.

Other than that it also has an emergency system

- Use of straightforward polycarbonate sheets with entryway check sensors to improve permeability and security.

- Alarm frameworks that go off when the case and filling materials levels go down.

- Emergency switches that you can use to stop the machine if there should be an occurrence of crises.

Don't forget to share this post!

Capsule Filling Machine Related Products

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine