9 Tips For Safely Operating a Capsule Filling Machine

Are you running a pharmaceutical business by producing abundance of capsules? But at the same time you are concerned about the safety and hygiene? If yes! You are lucky to have these concerns which are directly associated with the capsule filling machine you are using. So, here we have 9 Tips For Safely Operating a Capsule Filling Machine.

In this informative review, you will get to know about the various safety steps needed for operating a capsule filling machine. From wearing personal protective equipment till the maintenance of clean environment and personnel training, everything will be covered. So, before wasting any time just start exploring these tips one by one!

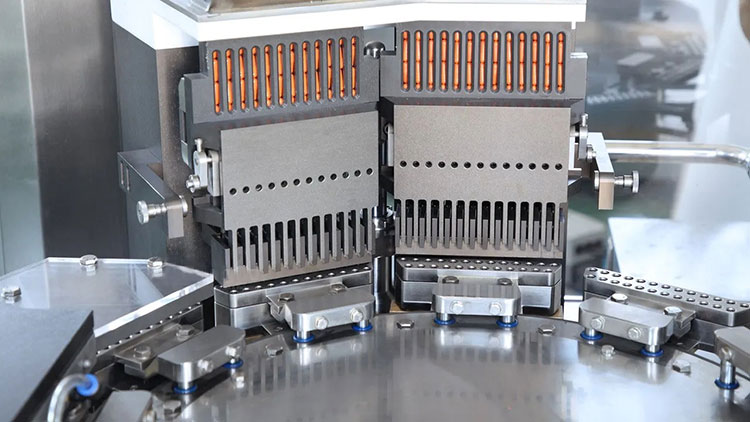

1.Adjustment of Structural Components

Structural adjustment of a capsule filling machine- Picture Courtesy: Syntegon

The very first tip you should always show concern for is the adjustment of structural components of a capsule filling machine. Know that it is the various parts which together make the composition of your machine. Unless and until you have not completed all the components along with their fixation in relevant location, your machine is not going to work properly. For this you need to:

- Check if all the main parts as well as auxiliary equipment are at hand.

- Take help from the manual checklist for different parts.

- Make sure each component is fixed in the relevant place in accordance with capsules specifications as the size of capsules vary, so as the, machine parts.

2.Training of Personnel

Training of personnel- Picture Courtesy: Syntegon

Training of personnel is often paid less attention and considered not as important for operating a capsule filling machine. However, this negligence can ruin your production process as well as the performance of machine. Similarly, it is necessary to train your working staff, so, they can bring the machine into operation in a right way.

Now, this training not only involves the basics of understanding start and shutdown button rather each aspect of machine must be taught. Some of the areas in which personnel should be trained include:

- Information about different parts should be given which can help in assembling and disassembling of the machine.

- The instructions should include identifying various buttons, control panel, and the configurations of machine to know the right tools for operating a machine.

- Training must include the cleaning, maintenance, as well as troubleshooting procedure in order to take right step at right time and avoid contamination and machine damage.

3.Calibrate The Machine

Calibration simply refers to the setting of electrical measurements. As a capsule filling machine is automatic it has computer type small operation panel with touch screen display which is used to communicate the desired commands into machine.

Now, this device is extremely useful as entire processing is carried out through the set commands. Therefore, the calibration of machine play eminent role which must be undertaken for safely operating a capsule filling machine.

4.Ensure The Emergency Button Works And Know The Shutdown Process

User pressing emergency stop- Picture Courtesy: groundhandlinginternational.com

Another significant tip for a successful operation of a capsule filling machine is checking the emergency button for its functionality. Dealing with such a heavy-duty machine require proper setting but there is still chances for emergency situation in that case you can swiftly take advantage of the emergency button.

This button is large in size with red color often placed on the front of machine. It just require a push to stop the machine. What you need to do is to keep checking this button for proper working. Also known how can you shutdown the machine in emergency situation.

5.Keep The Working Area Clean

Workers communiting in workplace- Picture Courtesy: Syntegon

Environment of the workplace is very important to ensure clean and tidy processing. It means that surrounding of your capsule filling machine must be free from contamination, pollution, and other such elements which may degrade the quality of capsules during production.

For this, you can place the machine in a room where there is adequate space for operating the machine. Try to install the machine in a ventilated area so the possible pollution may be get out of the room. Another important factor is to avoid operating a capsule filling machine in a messy workplace as it often causes confusion and disturbance during operation which leads to mistakes and parts wear and tear.

6.Set The Machine Before Starting

Control panel of a capsule filling machine- Picture Courtesy: ipharmachine.com

Isn't it unwise to just rush for start button when operating a capsule filling machine? Of course it is! In fact it shows a careless behavior when you avoid the most important step of setting whenever starting the machine. So, make sure you are properly carrying out all the post operation setting of machine which is necessary.

It includes the structural adjustment of various parts and their installation. Each component must be fixed in relevant place with right height and width. Similarly, operational setting is also very important which encompasses the modification of parameters as per the requirements of cycle.

Usually, this step is done by using the touch screen interface along with other buttons on panel. Moreover, you should check for any loose connection of electrical wires which may lead to electrical failures.

7.Wear Personal Protective Equipment

Personal protective equipment icon- Picture Courtesy: bigrentz.com

Capsule filling machine is an equipment utilized in either pharmaceutical, nutraceutical, or herbal industry all of which demand hygiene a prerequisite during production. From this fact, it may be analyzed that there is no room for contamination or pollution which is often caused when there is human interaction with machine.

This along with other essential factor which is associated with personnel safety, ask for another safety tip which is the wearing of personal protective equipment. These equipment include the use of coat for covering body, wearing hair net or hard cap, glasses, and gloves. Together, it helps in restricting the entrance of flying particles into eyes and the occurrence of cross contamination which may cause during operator intervention.

8.Monitor Machine During Operation

Capsules filling process- Picture Courtesy: makwell

It is not that you have settled the machine and run it for completing a cycle rather capsule filling machine should be operated in stages. This start from loading material into hopper till their final finishing in form of filling and capping capsules.

As soon as the process proceede, you are required to observe the operation and do minor adjustment. For instance, if everything is going well such as capsules opening, positioning, and ingredients filling etc., you may slightly increase the speed. Similarly, you need to take notice of the unusual sound or vibration caused during operation. These are some of the indicators that your machine has any kind of problem which can be easy tackled once found timely.

9.Clean The Machine After Use

Never forget to clean the machine after each use, especially when you are dealing with different types of materials. Skipping cleaning step leads to the buildup of contamination as a result of leftovers and residues. Thus, when you load another formula the previous one contaminate the next batch and reducing the quality of finished product.

For proper cleaning you should follow the underlying steps:

- Disassemble the detachable parts of machine including hopper, filling nozzles, and molds etc.

- Wash these components with non acidic and recommended detergent.

- Use a clean damp cloth to remove out debris from the rest of parts.

- Let all the parts dry properly and then reassemble them to the machine by taking help from user manual.

10.Maintain Regularly

User maintaining a capsule filling machine- Picture Courtesy: ruidapacking.com

Maintenance go side by side with a capsule filling machine. It is a best practice to regularly maintain the machine by looking into various aspects such as:

Parts Changeover:Parts which are frequently used and get worn with time needs to be timely replaced with new ones. Thus, make sure to keep checking the various components of machine on daily basis.

Lubrication:Movable parts of a capsule filling machine including conveyor belt, slides, and bearings function smoothly via lubrication. However, the lubrication oil gets contaminated with time, so, you need to remove the old one with new grease oil which is compatible to the machine.

Upgradation:The upgradation of current machine through customization and the update of software etc., for efficient functioning of the machine is also a crucial step for maintaining a capsule filling machine.

Conclusion

To put in a nutshell, we hope the above explained 9 Tips For Safely Operating a Capsule Filling Machine have helped you. It is important to take note of these guidelines when dealing with capsules production as it will be beneficial for your business. These are simple to adopt in your daily routine by just wearing personal protective equipment, setting the machine, monitoring operation, and conducting regular cleaning as well as maintenance. If you found these tips helpful make sure to visit our website for other such content. You can contact us just by a single click on the given website. Thank you!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine