8 Powerful Benefits of Tube Filling Machine

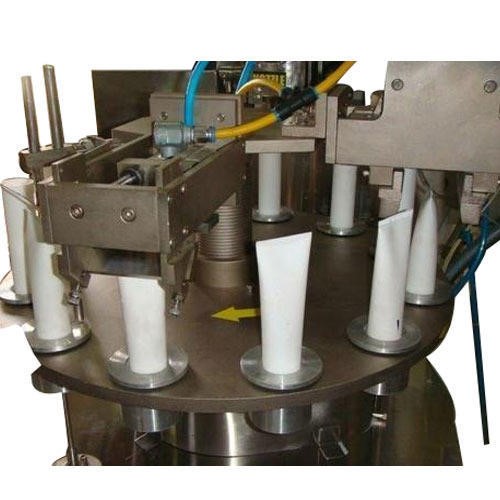

Tube filling machines are utilized for filling of polyethylene and covered tubes with gels, creams or different liquids, fixing them with hot air, stepping date and/or group No. also, cutting extra plastic on the tube ending, which emerges during the tube sealing process.

Various Tube Filling Machine Products

It is usable in filling a wide range of tubes, shapes, sizes, or limits. This machine can top and close tubes of 1.6 liters. It can likewise fill tubes with irregular shapes and can perform multiple tasks by filling both more thick and less thick items. This machine is adaptable, simple to work with since it has basic programming that is designed to fill tubes.

This machine is exceptionally precise in filling the tube with a similar amount of items. In contrast to the utilization of manual tube filling machines, which may bring about fluctuating amounts of items in tubes.

Let's expand our knowledge by knowing over-selves more about the benefits of the tube filling machine.

So, you gonna learn every advantage you need to know before making a purchase of tube filling machine.

1- Enhancing Overall Production Efficiency

It is a general truth that when we use advanced machines it helps in the efficiency in the production. In short, it always helps in increasing the production level. This part is about the explanation of that.

Production effectiveness is a monetary term portraying a level in which an economy or element can presently don't deliver extra measures of a decent without bringing down the production level of another item. This happens when production is reportedly happening along a production possibility frontier (PPF).

Production proficiency may likewise be alluded to as beneficial productivity. Efficiency likewise implies that an element is working at its greatest limit.

Truly these days, the main method of benefiting from a production cycle is by increasing the speed as much as you can do. The speed at which you produce and fill up your items and taking them to the market plays a vital function in the accomplishment of any business.

You should not forget one thing, there are no clients who are just ready to sit tight for you to take as much time as is needed and produce when it's easy for you to do so.

So utilizing this machine permits you to fill up the specific items in the shortest possible time and maybe given time. You'll notice that you rapidly top off small free-streaming items just as the high thick things in many containers in only one cycle. Actually, you can discover some tube filling machines with the limit of filling in excess of 120 tubes for every sixty seconds time frame.

Also, without a doubt you can envision the quantity of tube you can top off or every day at that rate.The main concern here is that this machine expands proficiency in the production cycle of various things to top off/ fill up in tubes.

2- Offering Reliability and Consistency

Reliability and consistency are as important factors as any other in this part of the article. This part discusses everything you need to know about these tube filling machines and their effect on reliability and consistency.

Reliability is being reliable or of performing reliably well. How much the aftereffect of a measurement, specification, or calculation can be relied upon to be precise.

Consistency in your business is unquestionably more significant that you can even imagine. Being reliable permits you to set up mindfulness, building trust and convey your administrations effectively and beneficially. Without it, your business is very likely to fail.

At the point when you decide to fill the item in tubes physically, hope to have a great change of volume or amount in each of the bottles. Human beings are prone to error and the chances are pretty high.

Obviously, there are a couple of estimating gadgets which you can use to remove such changes in the process .But that in any case, such gadgets may expect you to include additional time which can, obviously, influence the process of the production cycle adversely. So the second you decide to utilize this sort of machine you're ensured of repeatable, dependable and homogeneous fill off of every product in the cycle.

It doesn't make a difference if the fill is based on weight, volume, level of some other estimation so far as that is concerned. So, tube filling machines are gonna fulfill all your needs.

3- Reducing labor cost

Cost of the labor is a major factor in any type of the business. One thing which has been lessening with the passage of the time is labor because of the automation. So, this part is all about how tube filling machines help you reduce the cost.

The expense of labor is the total of all wages paid to labor, just as the expense of worker advantages and taxes paid by a business. The expense of labor is broken into both indirect as well as the direct costs. Direct expenses incorporate wages for the laborers that produce an item, including laborers for a mechanical production line, while indirect expenses are related with help workers, for example, workers who keep up industrial facility machines.

Assuming you're utilizing human resources to top off the tube for a specific item you're delivering, you can envision the number of individuals you'll require. It doesn't make a difference the technique that they'll use to top off the item.

What makes a big difference most is the amount of the cash you'll need to spend in the form of wages to them for the work they do. With a tube filling machine, you need near zero human work. All you require is an administrator who guarantees that each segment of the machine is running properly and giving you enough production per day.

AIPAK Tube Filling Machine

Furthermore, in an extraordinary way, you'll understand that having this sort of machine gives you a lot of relief in terms of work needs and charges to an minimum degree. Obviously, in the result of all this your profit ratio will increase and other than comfort and proficiency in the production cycle.

4- Providing Ideal Multitasking Solutions

Multitasking is the most vital demand in the 21st century. Both machines and human beings must be multitasking if they want to be successful in the marketplace. So, here it is discussed.

The ability of any business to more than one task at a single time is defined as multitasking. The discussion around performing multiple tasks has regularly been misdirecting with a greater part saying that it can't and should not be done. We can't stop ourselves, with life being as serious and as hectic as it is some of the time. Henceforth performing various tasks consistently is crucial.

Various cosmetic tube filling machine products

Let me reveal to you one reality you most likely didn't think about tube filling machines.

You'll barely come to know about any machine which is explicitly intended for a single item, compartment or cylinder. The majority of them permit you to set up various sorts of holders paying little attention to the size or shape.

Furthermore, the greater part of these machines can likewise deal with different products.Some of them can likewise top off both small and large as well as viscous and thin products as well. If your organization packs or bundles a few items in different holders, at that point the flexibility of this tube filling machine can be a definitive advantage for you.

So essentially, you require this machine for its adaptability capacity which additionally lessens your expense and upgrades your production level to the maximum extent.

5- Providing better working conditions

As along the working conditions are not good neither a machine nor a human being can work very easily and always have the problem.

The conditions in which an individual or staff works, including however not restricted to such things as enhancements, physical climate, stress and level of noise, level of danger and safety, and so forth.

The tube filling machines apparently require extensive set up regardless of what it looks like to you. What's more, that point should not be mistaken that the activity of the actual operation of the machine is a bit different and bulkier.

Truth be told, you'll just need a couple of hand changes occasionally especially when changing bottle from one bottle to another. Some of the basic settings including, speed of the pump, ordering times, and filling times among others will be determined by the touchscreen interface. And once you figure the ideal settings for a specific bottler fill up mix, you'll just need to rest and monitor the functions done by the machine.

So amazingly, utilizing tube filling machines empowers you as an administrator to encounter better working conditions.

6- Reducing Wastage

Every single penny matters. Right? So, why are you wasting the raw material of hundreds of dollars by using an old machine which doesn’t make sense in the 21st century.

Waste decrease, otherwise called source decrease, is the act of utilizing less material and energy to limit waste generation and safeguard common assets. Wastage of resources is more extensive in scope than reusing and consolidates approaches to keep materials from winding up as waste before they arrive at the reusing stage. Waste decrease incorporates reusing items, for example, plastic and glass compartments, buying more sturdy items, and utilizing reusable items, for example, dishrags rather than paper towels.

Utilizing a tube filling machine is perhaps the most certain method of keeping the items from useless wastage. Not at all like hand filling, which results in squandering or wasting a lot of the thing you're filling, this machine makes sure the up to mark standards result. With the end goal that it gauges the specific measure of item that you have to fill in every bottle/ jar or whatever consequently maintaining almost no wastage or very less wastage which avoids any inconvenience incidence.

Moreover, the machine just needs you to set the vital level to get into the tube appropriately,and you're all set.

7- Available for upgrading

What to worry about when you can model something according to your own required customization. Thus, tube filling machines are what give you an opportunity to do so.

Raise (something) to a better quality, specifically improve (gear or apparatus) by including or supplanting segments: the expense of overhauling every workstation is around some measure of cash updated computer.

An improved or more modern of something, esp. In terms of machines.

Utilizing this sort of Tube filling machine offers you the chance to develop depends on your customer. You can begin with a basic tube filling machine which has not many fill heads suppose like four, six or even eight. But with time, the production level will develop. Also, this would imply that the requirement for more fill heads become a need.

Easy to upgrade tube filling system

So you'll need to get a tube filling machine with much in excess of 16 fill heads which permit more bottle/ jar/ or containers to top off in a single cycle.

Justifiably, the model of the machines will contrast with respect to limits, and the speed will rely upon components like bottle size, shape and item itself. Indeed, the fact I'm attempting to put over, for this situation, is that utilizing this sort of machine permits you to develop from a fundamental to a complex machine. Furthermore, it's a very decent component on the grounds that as you develop, you additionally learn more points of view encompassing the machine.

8- Guaranteeing safety

If you lose one step you almost lose every step and it indeed costs a lot of money to business. Safety first and this machine can help you anyway and anyhow.

In any case if something like this happens: If the temperature is very low, pressure of the air is very low, if the tubes to be filled are excessively high or excessively low, the motor torque is bit higher, not enough filling volume inside a tube or the associated cartooning machine is faulty and so forth, a sign of the any type of the problem will be sent off the LED show to operator who is operating machine so they can correct, so the filling, sealing quality and production quality can be controlled. The hopper is outfitted with an automatic blender which encourages the filling process to be all the more easily. Optional filling hoppers with temperature and liquid level control function are available for selection.

A video about fully automatic machine :

It has an enormous touchscreen used to control the machine. Graphical status for observing the activity cycle is additionally accessible. The hardware has an in-side peristaltic pump that is utilized to set it up in a lot speedy way. It works at fast and precisely with or least wastage of items. The advancement of speed in filling has expanded the organization profit returns.

Filling being done with sealing

The machine has an enormous and adaptable surface. This helps in permitting the convenience of numerous tubes during the filling cycle. It can be changed over quickly, and this advances the filling of different items. It likewise helps in expanding its productivity.

The utilization of this machine assists with protecting the items from any type of contamination. It keeps the administrator from harming the items like pesticides and different synthetic substances since human contact with the items is very near to Nothing. This machine creates less noise during this process. It is easier to clean and maintain. When there is no tube, there is no filling.

Conclusion

So that is pretty much the much data that I needed to give to you with respect to tube filling hardware. I'm confident that at this point you're very educated and that you realize a lot of information related to tube filling machines which you didn't have a thought of. Furthermore, it is basic since it by and large makes your work simple particularly with regards to selection or importing.

Tube Filling Machine Related Products

Tube Filling Machine Related Posts

Tube Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours