6 Advantages You Must Know About Tablet Counting Machine

A tablet counting machine is a machine that will help you in counting the tablets or capsules that you produce. The manual technique for counting of capsule might be hazardous and slow as well. This possibly on the grounds that you need to remain in one spot the entire day as you check the number of capsules and count them.

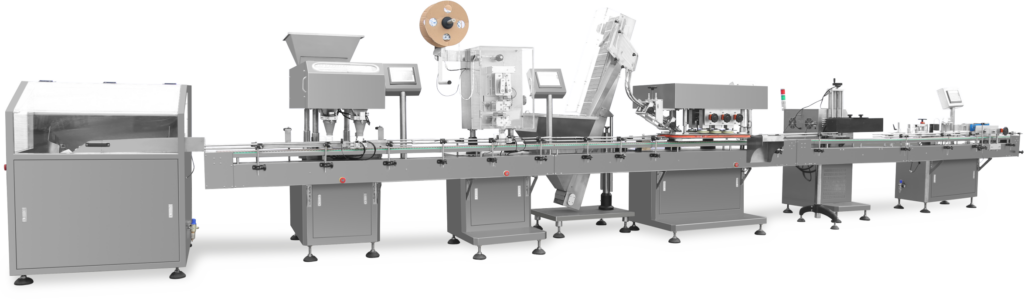

AIPAK Tablet counting line

You can improve adequacy in your capsules counting process by placing assets into extraordinary modified tablet counting machines. It improves precision, profitability and consistency, something you probably need.

In this article you will learn about every possible about advantage of tablet counting machine.

1- Simple of Running

Operation of everything is considered vital if a product has lots of technicalities it is always hard to handle and employees need training. However, in this case the tablet counting machine. It is very easy to manage and handle.

The tablet counting machine is commonly simple for you to work with. You won't need to stress over the machine separating you. You won't need to stress when you have 50 or so bottles which should be packed every day as you will have the option to get the errand finished on schedule. You will just need an alignment change so as to continue the various sizes of the capsules. The errand of cleaning will be simple too as it will just take a couple of moments to do so.

- Start: It has a start button which is prominent and just needs one touch to start the machine.

- Emergency stop: In case, if any kind of mishap happens there is always an emergency button which would help you to stop.

- Speed control: This helps you to control the speed of the machine in capsule counting.

2- Precision of Counting

Precision is the number of the defects a machine creates while in running. When you talk about this machine it really does not have any side effects. Though, it comes with a very less margin of error.

You make certain of getting incredible performance from the tablet counting machine as a result of its working mechanism. You should not expect any mistakes as it does have precision in the counting cycle. As much as the machine doesn't break the drugs, it can likewise distinguish any type of breakages. The programmed framework will alert you of the broken capsules or tablets while counting.

High precision tablet/case counting machine suits for unpredictable shape and ordinary state of tablet and capsules including necessity in bags and bottles. With an easy to use control framework and touchscreen, it is not difficult to work without preparing and adjusting to boost productivity and save downtime.

You do have the ability to provide tablet counting machines for single to quad head units. These tablet counting machines are additionally explicitly intended for situations where items are hard to count, as clear capsules etc.

At the point when workers commit errors in counting, they need to start from the very beginning once more. This outcomes in a great loss of time and cash. The key reason for a capsules counting machine is to accurately count and precision would also increase.

- Imagine accomplishing an error in the counting of under 1%.

- Yes, that is the thing that you get when you utilize a tablet counting machine.

- This level of correctness originates from innovation in development of tablet counting machines.

- It ensures 100% accuracy in the results from when it has issue as a result of accumulation of dust in the plate sensor window.

- The precision level guarantees that patients get the right measurements and drug.

3- Speedy & Accurate:

If you are looking for a better production rate of-course less time during the production this part is for you. Accuracy is another point to ponder about. The accuracy of the tablet counting machine is around 99.5 to 99.9 percent which makes it unique among other products.

Speed is among the top factors that must be highlighted while buying a machine. Most capsules counting machines will guarantee speed yield regarding bottles every moment (BPM). Producers normally utilize a capsules or medicine size tablet (1/4" Diameter X 1/8" Height) with 100 tablets for every bottle to quantify BPM. It is likewise critical to take note of that a packing line is just as quick as its slowest bit of equipment.

That’s why if a bundling line contains a machine that just finishes 30 bottles for each moment; the filler doesn't have to surpass this speed. Numerous factors direct the maximum velocity that a machine can finish a fill cycle. Item control, Design nature of the counting mechanism assembly and the quantity of bottles to be filled at the same time have the best general impact on speed. In case of tablet counting machines it has a reliable speed.

Precision is something that is the most significant capacity of the tablet counting machine. The FDA orders that tablets and capsules that fall under its purview must be considered methods for deciding the amount per bottle. Most tablet counting machines achieve this by identifying a capsule as it free falls past a sensor or camera framework. The refinement and capacities of these counting frameworks changes incredibly from machine to machine. The better quality of the machine, the more probable it will have a more refined and capable counting framework.

- In a normal tablet counting machine, utilize a sensor (generally an off-the-rack name brand sensor, not explicit to the application) to verify that there was a change in signal and will consider this change as a decent tablet.

- While a decent tablet counting machine will utilize customized sensors or cameras to identify a capsule and check and notice any little change in the machine.

These frameworks can typically decide whether the item that fell through is complete or broken, or if at least two pieces of a single capsule can distinguish and do not count them as two capsules, though a good framework would consider that as a one capsule. The better quality tablet counting machines normally have quicker interchanges and reset times considering quicker throughput of items without sacrificing accuracy because of time lag error.

4- Change-over time / Parts and Prevention of Contamination

In manufacturing, changeover is the process of converting a line or machine from running one product to another. Changeover times can last from a few minutes to as much as several weeks in the case of automobile manufacturers retooling for new models.

Another significant thought is changeover. Perhaps the greatest advantage to a tablet counting machine is that it doesn't need an enormous number of items or containers explicitly to change parts. This minimizes expenses regardless of whether countless various items are filled by a similar machine. Containers are regularly the main part needed change with a capsule, yet various producers or manufacturers may have extra change parts needed to run various items.

To take care of the pollution, machine parts that come into direct contact with the item should be cleaned between runs. This is a pretty much time taking cycle that cuts into the overall production of tablet counting machine packing line. It is along these lines significant that the tablet filler can be dismantled rapidly and without any problem.

Most machines will permit contact parts to be eliminated without the utilization of devices. This spares significant time and permits administrators, who may not be OK with devices, to dismantle the machine for cleaning. The breakdown of each machine contrasts essentially. This is a significant perspective to the worldwide usefulness of the machine.

- In most cases, employees wear gloves and other protective gear as it may be required while handling the pills. However, this does not eliminate the risk of contamination of the pills and bottles. A tablet counting machine reduces the risk of contamination as it does not include any such things like touching etc.

- This way this machine saves you a lot of the time because change over or the parts to operate does not consume anytime at.

5- Easy to clean and durable

How easy a product can be cleaned when there is dust on that and how long a product lasts after buying it without any issues is a considerable factor to highlight while buying. Cleaning and durability is as important as anything else in the machine.

All machines must be cleaned between item runs. While contact parts are typically taken out for cleaning, different zones of the machine may require cleaning also. Some machine plans have represented this with flush surfaces and enormous access zones. Different machines don't address this issue. A machine that is hard to completely clean can make issues for counting.

A few machines in the business will make accessible versatile stations explicitly intended for a specific machine's contact and change parts. This takes into account simple parts of the board, just as simple cleaning.

The portable stations are planned with the goal that the whole station can be washed down and all parts will be orientated for ideal introduction. Most tablet counting machines have cleaning systems, a very much planned machine, in this regard, you can improve productivity.

A tablet counting machine is a significant purchase of a pharmaceutical industry. It is incredibly shocking and frustrating when a generally new bit of machine fails. With an end goal to minimize expenses, some machine developers will utilize reasonable or cheap parts and materials in their machines. After some time these parts of the and materials breakdown, as they regularly have a lower cycle life or you will be worried. It is critical to choose a machine that has a good form and uses better parts.

In that case machines at AIPAK are very high quality and every part of it is stainless steel which increases the durability of the product.

6- Various Models

Variation in the products always capture the eyes and tablet counting machines offer that as well. It does have a wide range of products in their models.

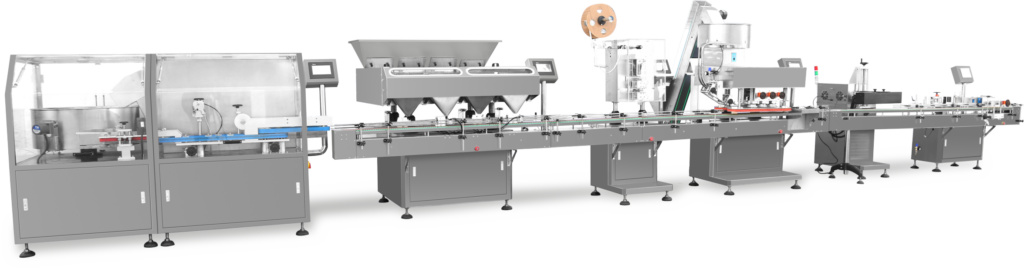

AIPAK Various Tablet counting machine tablet counting line

You have the opportunity to choose a reasonable machine from the 8 – 12-16-24-32 channels. Choice would generally rely upon your production necessity.

Some of the features of the machine are customized too relying upon your needs.

Manual Hand worked capsule countering machines offered are exceptionally helpful apparatuses to all Pharmaceutical and other medication makers for physically counting the filled capsules. This is exceptionally minimal apparatus reasonable for research, lab reason; it can likewise be utilized in small enterprises having extremely low production rate.

In fact, apart from the these above mentioned points,there are other benefits you can get from a tablet counting machine.For example:

The mistake of including and pressing the machine in the bottle is over 99.5%, higher than line standard.

Pressing component of the tablet checking machine has won the national patent, no harm to the material when closed or open.

Embrace against high dust the new tablet counting machine innovation, the tablet counting machine at present can work ordinarily under the high dusty climate.

The drug store tablet counting machine can tally and discriminate the material including tablets, soft capsules, hard capsules ( non transparent and transparent).

This tablet counting machine can successfully separate and can count the enormous, stick material and irregular.

Conclusion:

The controller based tablet counting machine and observing framework will depict and show the quantity of capsules has been passing the sensor. This framework is to count the capsules by utilizing the IR sensors and regulator. You can include other capacity for capsules considering machines such conveyor and packaging and so forth. This framework is considered as a fantastic achievement. The tablet counting machine works consistently with the electronic equipment and the program works well with no significant mistakes happening. It is ideally to decrease human contact in capsules counting. This framework is valuable for the Pharmacist industry.

Tablet Counting Line Related Products

Tablet Counting Line Related Posts

Tablet Counting Line Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine