5 Steps To Take You To Fully Understand The Wet Granulator Machine

According to incomplete statistics, the wet granulator machine in the pharmaceutical industry has accounted for 70% of all solid preparation granulation equipment, and it has brought many convenience to human’s life.

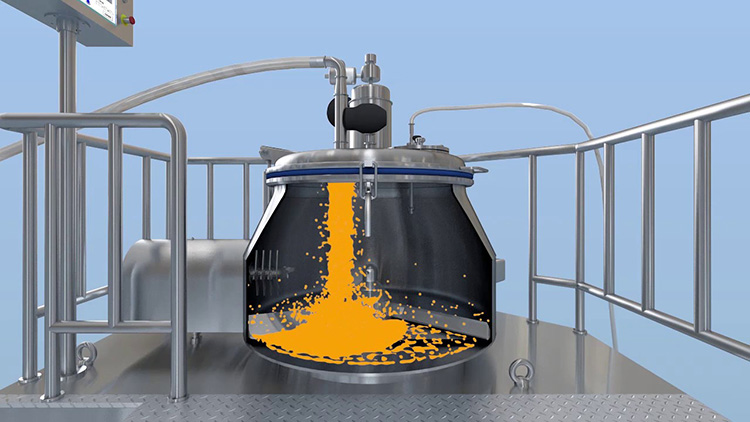

As one of the granulation machines, the wet granulator machine has been used in many industries due to its advantages, and its working principle is not complex, which is used to develop wet powder into the required particles, and it is also possible to pulverize the bulk dry material into desired granules. Its main feature is that the screen mesh is easy to install and disassemble, and the tightness can be adjusted.

So, how much do you know about wet granulator machine? Have you seen his work process? Or have you ever seen a product made by this machine? Today, we mainly take you to fully understand the wet granulator machine from the following 6 aspects

Preparation before production

First of all, you need to check whether the air compressor is running normally and whether the oil level of the compressor is in the control line. Then drain the condensed water in the compressed air line.

Second, check whether the water source is smooth and maintain the normal pressure of the water.

Third, check whether the discharge door of the wet granulator is closed and matched, and whether the limit switch on the discharge port door is in place.

Fourth, after switching on the power and air source, it is necessary to check the operation of the discharging piston at the discharging port, and whether the opening and closing of the lid of the material is normal. The limit switch of the lid is to play the role of locking position.

Production operation

First, connect the power supply, air source and water source. Rotate the air source transfer valve to the ventilation position, check the air pressure, keep P air ≥ 0.5mpa, and close the water transfer valve to prevent water overflow. The water is only used for cleaning the machine.

Second, close the discharging piston and open the lid of the material pot when the door signal light is on. Pour the raw materials, accessories and adhesives to be processed into the pot, and close the lid of the material. Operate according to SOP of the product.

Third, adjust the time relay according to the time required by stirring. First turn on the motor of the cutting knife, then turn on the motor of the mixing slurry. You should put your car in slow gear first and then in fast gear.

If the proportion of adhesive is more than 10% of the slurry, the slow car should be started 15 seconds after the slurry is added before the fast speed can be opened to prevent the motor load from being too heavy.

Where the proportion of adhesive ≤10% slurry or ethanol as wetting agent from the feeding mouth into the pot, in the case of the material is sticky, should avoid opening fast.

Fourth, after granulation is completed, put the hopper under the discharge port, open the discharge piston, start the slurry mixing, and discharge the wet particles. When doing the next material particle, the discharging piston must be kept flexible and anastomosed with the material mouth.

Fifth, during the whole process of preparation, feeding and granulation, as well as cleaning the material pot, ventilation should always be maintained.

Wet granulator machine cleaning

First, switch on the power supply, water source and air source, and close the discharging piston.

Second, rotate the three-way ball valve to the water position, observe the amount of water, and then switch to the ventilation position.

Third, close the cover of the material pot and turn on the mincing motor of the stirring motor for cleaning. And clean the feed pan.

Fourth, after cleaning, open the discharge piston and drain the water. Then open the outlet door and clean the outlet.

Fifth, remove the water in the material pot, clean and wipe the outer case of the machine, and do no trace of water.

Safe operations

First, due to the effect of the limit switch on the balance support, when the material pot cover is opened, the electrical circuit should be locked, and the motor should not start.

Second, the travel switch on the discharging mechanism is connected with the control circuit of the electrical box. When the knob on the outlet door is released, the motor should be powered off. The threaded connection design can ensure that the opening of the nozzle door, the time required is longer than the inertia movement time of the motor after power failure.

And when the outlet door is opened, the motor should not start, otherwise, an electrician should check the limit switch. After opening the outlet door, do not allow to operate the discharging piston, in case the piston is damaged.

Third, the wet granulator machine is equipped with a pressure relay. When the air source pressure is lower than 0.5mpa, the power supply is automatically cut off and the operation cannot be carried out. Therefore, the air source pressure should not be lower than 0.5mpa to ensure the normal operation of the equipment.

Fourth, the exhaust holes and observation holes on the lid of the material pot are equipped with protective strips, which should not be removed. In addition, the device installed on the machine should not be removed at will.

The Maintenance of wet granulator machine

In order to ensure the sealing effect of the main stirring seal, the air pressure should be checked every shift. When the pressure is lower than 0.5Mpa, the machine cannot be rotated. The sealing ring should be cleaned every time the product is changed. After cleaning the material pot, the remaining steps are as follows:

First, rotate to the left and remove the centrosome.

Second, remove the pad and remove the stirring blade with the slurry remover.

Third, loosen and remove the screw, and then remove the sealing component.

Fourth, clean the sealing cavity with compressed air, or clean the sealing cavity with brush and water. If the machine is cleaned with cleaning solution, the cleaning solution can be discharged from the discharge pipe.

Fifth, when the seal is dry, the flange of the shaft seal ring is coated with the lubricant consistent with the product.

Sixth, assemble in the opposite order as above. If the seal needs to be replaced, it should also be carried out according to the above steps.

Seventh, outlet door: in order to ensure the normal operation of the piston of the outlet door, the air pressure should be checked, not less than 0.5mpa, otherwise the piston can not act.

Eight, piston at the end of each class should be clean slide bar, and add edible lubricating oil.

Ninth, check whether the seal ring on the piston door is damaged, and replace it in time to prevent drug leakage during production.

Tenth, the piston of the outlet is coated with a stainless steel leather. When installing the outlet door, you can not use a lot of strength, otherwise it is easy to damage. Apply force to the front cone when installing.

In the process of traditional Chinese medicine and Western medicine, the wet granulator machine plays an indispensable role. With the continuous development of the pharmaceutical market, people's expectations and requirements for the pharmaceutical industry are becoming higher and higher. If the wet granulator machine wants to have better development in the future, it must continue to bring forth new products with the market changes.

Don't forget to share this post!

Granulator Machine Related Posts

Granulator Machine Related Products

Granulator Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide, tips and trends sent straightly to your box? Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine