3 Things We Can’t Ignore About Powder Filling Machine

Canned powder is commonly found on supermarket shelves, some slap-up and delicate packaging of edible powder, it is because of its exquisite and portable packaging that many people will use it for gift giving, socializing, relationship, etc.

During the traditional festivals, its consumer market is also very considerable. Nowadays, as the environmental concept deeply rooted in the hearts of human beings, the canned food becomes the “latest excitement” of the market.

It not only can be used as food , but canned products can also be degraded and processed, and its canned powder is easy to store and reserve, which is gradually increasing in household consumption. The powder filling machine can reduce cost and increase efficiency for powder manufacturers, and then it can also establish a good corporate image for the company, and lead the company to quickly occupy the consumer market.

The scope of application and advantages of powder filling machine

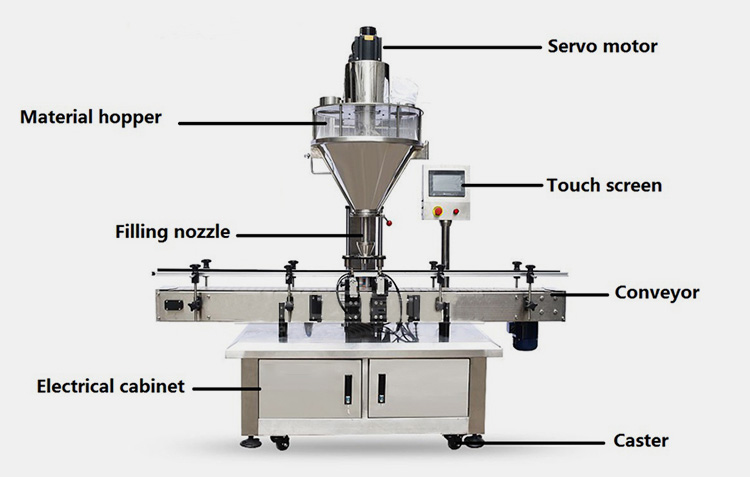

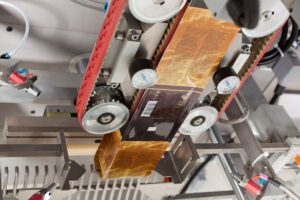

The powder filling machines have different equipment models for different packaging styles and packaging volumes. Common powder filling machines on the market include linear powder filling machine,double-head powder filling machine,rotary powder filling machine.

Because of the strong fluidity of powder, light quality, easy to float, it is difficult to avoid a series of problems caused by dust on equipment and factory processing personnel in the filling process. However, the automatic powder filling machine developed and manufactured adopts the submersible filling method, which can greatly reduce the problem of dust pollution.

High degree of automation, high filling accuracy, simple operation, can reduce manpower input for powder manufacturers. The automatic powder filling machine effectively solves the problem of dust packaging, and efficiently assists the development of powder processing industry.

The Powder filling machine can fill: protein powder, nutrition powder, walnut powder, milk powder, coffee powder, coffee companion, collagen powder, plant protein powder, starch, seasoning powder, ready-mixed powder and other powder.

In order to comprehensively improve the problems encountered in the filling process, the fully automatic powder filling line developed and manufactured is integrated into:

Supporting tank, vibration, metering filling, vibration, weighing feedback, supplementary filling, check weighing, out-of-tolerance rejection, out of the tank in one.

Greatly improve the production efficiency, but also reduce manpower input, simple and convenient operation, more automation.

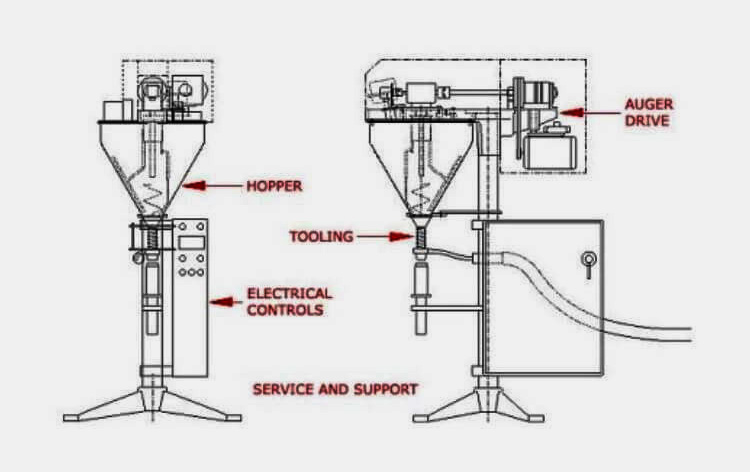

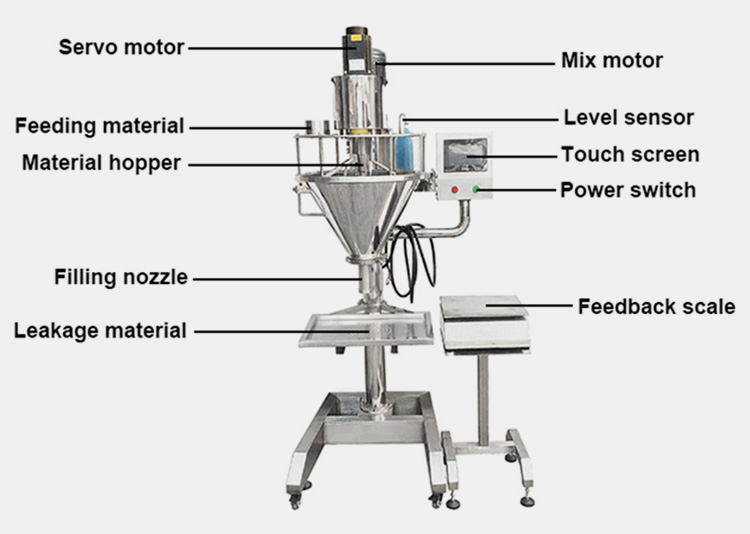

Equipment characteristics and working principle

The features of the powder filling machine

First, single row double head filling, main filling and supplementary filling, to ensure high canning accuracy.

Second, servo and pneumatic system control tank support and horizontal tank, accurate positioning, fast speed.

Third, servo motor and servo drive control screw, stable performance, high precision.

Fourth, all stainless steel structure; Horizontal open type material box (inside and outside polishing), cleaning is very convenient.

Fifth, PLC control, touch screen display, easy to operate.

Sixth, the weighing system with high reaction speed ensures the realization of high canning speed and precision.

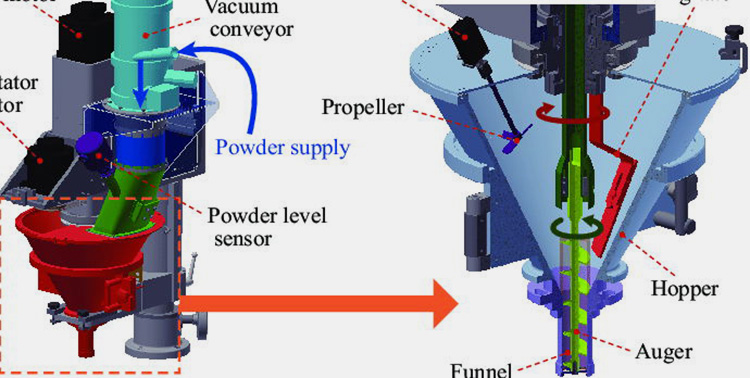

Working Principle

First, the powder filling machine is a combination of machine, electricity, light and instrument, controlled by single chip microcomputer, with automatic quantification, automatic filling, automatic adjustment of measurement errors and other functions.

Second, fast speed: screw blanking, light control technology.

Third, high precision: using stepper motor and electronic weighing technology.

Fourth, the filling range is wide: the same quantitative filling machine can be installed within 5-5000g by adjusting and replacing the cutting screw of different specifications through the keyboard of electronic scale.

Fifth, a wide range of applications: there is a certain fluidity of powder, granular materials can be.

Sixth, suitable for bags, cans, bottles and other packaging containers powder quantitative packaging.

Seventh, the error caused by the change of material proportion and material level can be automatically tracked and corrected.

Eighth, photoelectric switch control, only manual bagging, bag mouth clean, easy to seal.

Ninth, with the material contact parts are made of stainless steel, easy to clean, prevent cross contamination.

With further integrated into the intelligent, powder filling machine self-inspection is bound to be more perfect, and in the use of filling machine, you must attention to understand the operation of the filling machine and operating norms, the daily production, the powder filling machine operation specification is what? Let's take a look at it.

First, the sensor is a high precision, high sealing degree, high sensitivity device, it is prohibited to impact and overload, the process of work shall not contact, not maintenance is not allowed to disassemble.

The second production to often observe the mechanical parts, to see whether the rotation, lifting is normal, there is no abnormality, whether the screw loose.

Third, check the equipment ground wire, contact requirements are reliable, often clean the weighing platform, check whether there is air leakage in the pneumatic pipeline, whether the gas pipe is broken.

Fourth, if the use of a long time to empty the pipeline material automatic filling machine.

Fifth, the reducer replaces the lubricating oil (fat) every year, checks the chain tightness, and adjusts the tension in time.

Sixth, do a good job of cleaning and sanitation, keep the surface of the machine clean, often remove the material on the scale body, pay attention to keep the electrical control cabinet clean.

Thanks to the development of science and technology, the present powder filling machine has automatic detection function and visual detection report, normal operators who have received simple training can understand, and in addition to the basic chip detection, it needs to pay attention.

The correct use of the powder filling machine specification can prolong the service life of the machine, and can effectively protect the safety of personnel and the machine, the use and maintenance of the filling machine need to pay attention to the matters let us come to understand it again.

Maintenance and Repair

First, because the powder filling machine is an automatic machine, so ring-pull bottle, bottle pad, bottle cap size are required to be uniform.

Second, before starting the filling equipment, it is necessary to turn the machine with the handle to check whether there is any abnormality in its rotation, and confirm that it is normal before driving.

Third, when adjusting the machine, the tool should be used properly. It is forbidden to use too large tools or too hard to remove parts so as not to damage the parts or affect the performance of the machine.

Fourthly, when the machine is adjusted, the loose screws must be tightened, and the machine can be run only after the handle is turned to see whether the action meets the requirements

Fifth, the machine must be kept clean, no oil, liquid medicine or glass debris on the machine, so as not to cause corrosion of the machine, so it must:

The machine in the production process, timely remove the liquid medicine or glass debris.

The machine surface should be cleaned once before the shift, and add clean lubricating oil in each activity department.

It should be cleaned once a week, especially the places that are not easy to clean in ordinary use or blown clean with compressed air.

At present, with the expansion of market demand and the improvement of requirements, enterprises update the powder filling production line more and more frequently. At the same time, powder filling production line and other related products are also improving with the market demand, and the development trend is gradually toward the degree of automation.

In the future, powder filling production lines will still occupy an important position. So it is imperative to know more about powder filling machines.

Don't forget to share this post!

Powder Filling Machine Related Posts

Powder Filling Machine Related Products

Powder Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 189 7157 0951

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine