3 Side Seal Pouch Making Machine: The Complete FAQ Guide In 2025

You would probably have an unlimited list of questions about 3 side seal pouch making machine if buying it for the first time, Isn’t it? Being an expert in manufacturing equipment, our goal is to offer the best solution for all your queries and make you in the right direction of purchasing it.

3 side seal pouch making machine: The complete FAQ Guide in 2023 article has common questions with the best guidelines on how to run, troubleshoot, and other matters you always encounter.

So let’s hook to the topic now!

1.What is 3 Side Seal Pouch Making Machine?

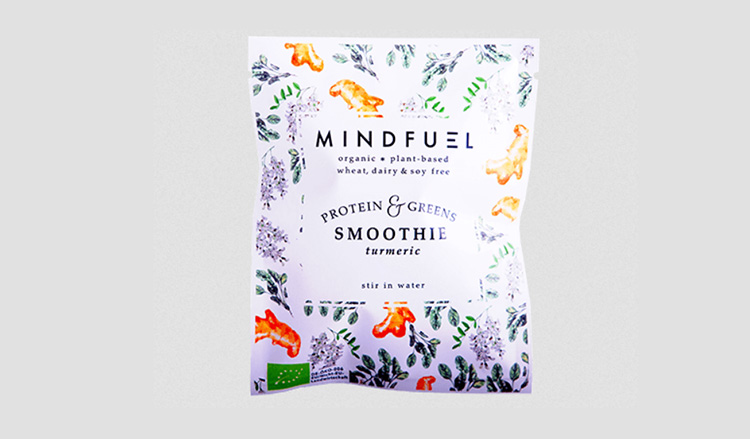

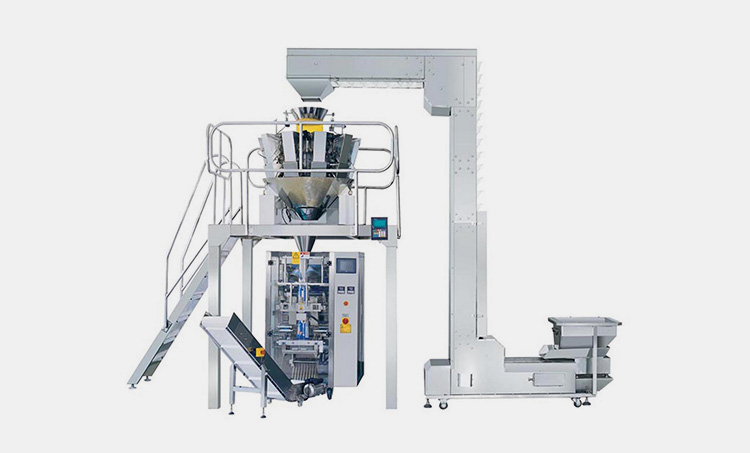

These machines are an important part of packaging machine lines. 3-side seal pouch making machines are high-performance equipment that uses plastic film roll for producing 3-side seal pouches. These pouches are usually sealed at the sides and top.

3-side seal pouch making machines fold packaging film from one side and seal the other edges of the film to manufacture a 3-sided seal pouch.

These instruments can be customized with various accessory parts for making 3-sided seal pouches with zippers, tear notches, valves, sprouts, hanger holes, etc.

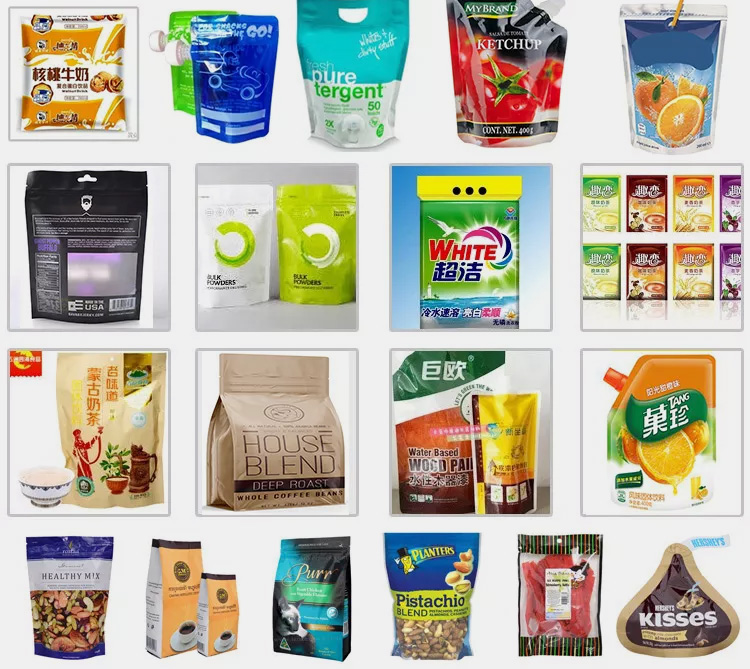

These devices are used for fast pouch packaging in various industries such as pharmaceutical, medical, food, cosmetics, pet food, confectionery, cannabis, etc.

2.Where do you use the 3 Side Seal Pouch Making Machine?

3-side seal pouch making machines are versatile and robust equipment, commonly employed in different industries across the globe for an efficient and speedy pouch packaging.

Some important industrial uses of these machines are:

Pharmaceutical Industry

Yes, these extremely efficient machines are routinely used in the packaging of pharmaceutical powders, pills, syrups, emulsions, and suspensions. These flat pouches protect pharmaceutical products from contaminants such as microbes, chemicals, dust, air, and moisture. Furthermore, these pouches are important in increasing the shelf-life of products.

Health and Medical Industry

Have you seen medical devices such as syringes, scissors, surgical blades, gauze, etc. in pouches? These are packed in transparent flat pouches using 3 side seal pouch making machines. They insert medical instruments in tear-notch zipper pouches for barrier protection.

Food Industry

Everyone loves snacks and confectionaries. These are available in stylish 3 side seal pouch packaging. This packaging is produced by 3 side seal pouch making machine.

Not only snacks, but these machines are also used for packaging liquid foods such as gravies, dressings, condiments, and many more in the food industry.

Coffee and Tea Industry

Coffee (ground, bean, and instant) and tea (leaves, ground) are packaged in elegant 3-side seal pouches by the 3-side seal pouch making machines. These devices are essential in preserving the aroma, freshness, and taste of tea leaves and coffee beans. This equipment packs coffee beans in valve flat pouches.

Cosmetic Industry

Different beauty products such as bath bombs, gels, serums, dyes, essential oils, etc. are packaged inside eye-pleasing graphical 3-side seal pouches by these machines. These pouches protect cosmetic products from environmental agents and debris.

Chemical Industry

Often 3 side seal pouch making machines are employed in the chemical industry for packaging detergents, cleaning powders, borax, and washing soda. 3 side seal pouches protect chemicals against moisture and oxygen.

Pet Industry

3 side seal pouch making machines are needed for the pet industry. In this industry, these handy machines are used for packaging cat biscuits, dog treats, and other munches for pets in stylishly designed pouches.

Agriculture Industry

3-side seal pouches are commonly seen in the agriculture or gardening industry. These pouches of agricultural products such as fertilizers, soils, seeds, feeds, and powder are packaged by 3 side seal pouch making machines.

3.How Does a 3-Side Seal Pouch Making Machine Work?

Working of 3 side seal pouch making machines is precise and accurate with each step occurring at the right time for making perfectly designed pouches.

The steps involved in working are:

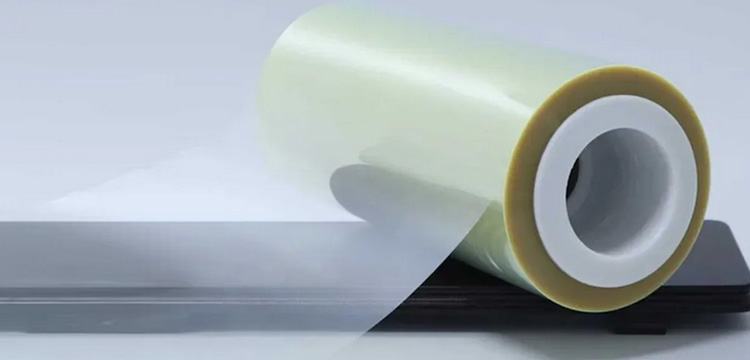

Loading of Packaging Film

First, at the start of the pouch-making operation, packaging film is placed on the film mandrel by the operator.

Film Unwinding

The packaging film is unwound or unraveled by the rotation of a shaft. This shaft is rotated by pneumatic systems or servo gear motors. The pulling of the film by the pull belts creates tension in the film which assists in moving said film across the machine. The film is folded after unwinding and is passed to rollers.

Different kinds of rollers located in a 3-side seal pouch making machine keep the film under adequate tension and prevents the film from drifting away.

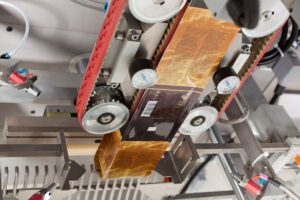

First Sealing

The film packaging travel to side sealing jaws that seal and glue the two layers (front and back) of film sideways. As a result, a partial 3-side seal pouch is formed.

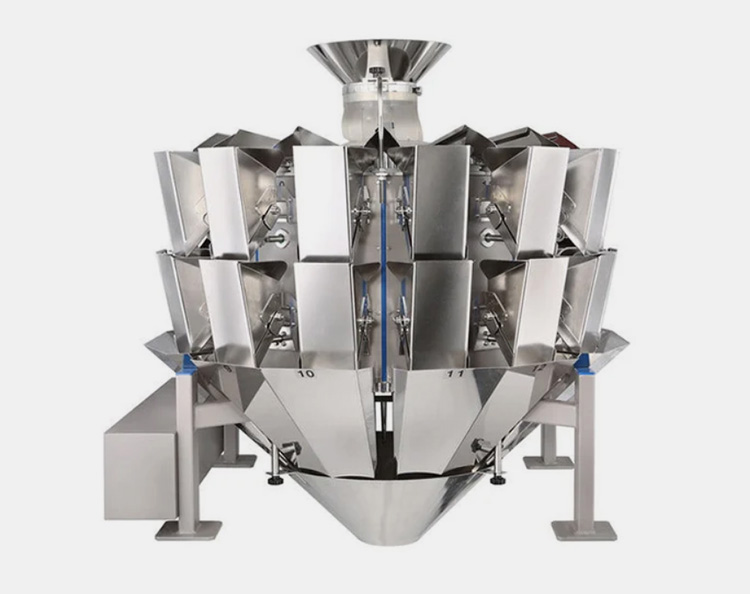

Pouch Filling

The products to be filled are loaded in the hopper from where they go to the filling station for packaging inside partially formed pouches.

Second Sealing

After product filling, the filled pouch is passed underneath the second set of sealing jaws, also known as horizontal sealing jaws. These sealing elements are employed for the final and top-sealing of the pouch. The pouch is fully sealed after the application of horizontal sealing jaws.

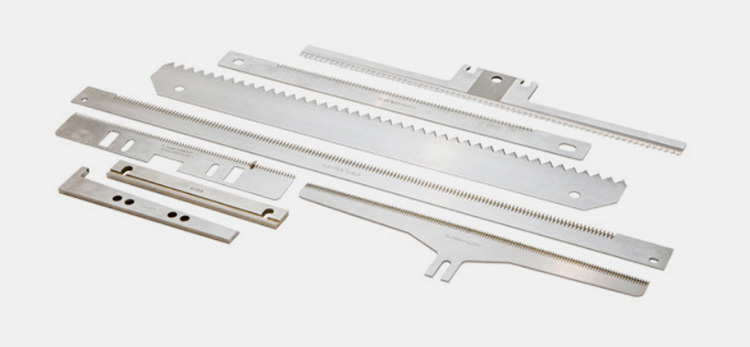

Cutting

At the final stage, the completely sealed pouch goes to the cutter. The separation and cutting of pouches take place through the action of cutting blades. Then these 3 side seal pouches are discharged from the machine.

These pouches are collected into collection bins or are moved to cartoning machines for packaging into cartons.

4.What are the main parts of the 3 Side Seal Pouch Making Machine?

These machines are synchronized automation in which every component has a defined role for rapid pouch production.

Some main parts present in the 3 side seal pouch making machines are:

Film Unwinder

The film loaded on a shaft, is unwound by a set of devices called film unwinders. These components present in 3-side seal pouch making machines are continuously for unwinding film rolls.

Film unwind mandrels are static and are often rotated through power provided by a pneumatic or friction system. Occasionally, these mandrels are moved by gear motors. The tension created by film pulling is vital in packaging film unwinding.

Rollers

These machines have multiple roller devices including unwinding buffer rollers and center partition rollers. These rollers assist in the stability of the film web feed. Moreover, the function of the rollers is to maintain the firm tension of the film which prevents slippage of the packaging film.

Pneumatic Systems

These piston pressure systems are used for powering film unwinder devices and rollers. The movement of a piston in a cylinder creates necessary pressure which aids in the movement of film across the machine.

Hopper

It is a cone-shaped structure usually found at the upper part of the 3 side seal pouch making machines. The materials for filling are loaded in these components usually at the start of the operation.

Filling Unit

This part consists of feeders (auger, vibratory) or liquid fillers (volume or gravity or pressure) as well as filling nozzles to insert and load the solid contents or liquid materials inside the 3 side seal pouches.

Side Sealing Jaws

These are also known as vertical sealing jaws. These are the first set of jaws used in 3 side seal pouch making machines for sealing the sides of the film. These sealing bars are heated with heating elements for sealing two film layers together.

Bottom Sealing Jaws

These sealing devices are also known as horizontal sealing jaws. These sealing jaws seal the horizontal side of the pouch (top or bottom) after the side sealing. These hermetically close the packaging containers.

Servo Cutters

These are employed at the end of 3 side pouch making operation for separating consecutive pouches. The cutter descends and cuts the edges of newly formed pouches.

HMI

This is a touchscreen interface used for setting operational parameters such as bag length, product weight, temperature, pressure, etc. These highly intuitive components also display the report of the whole pouch-making operation.

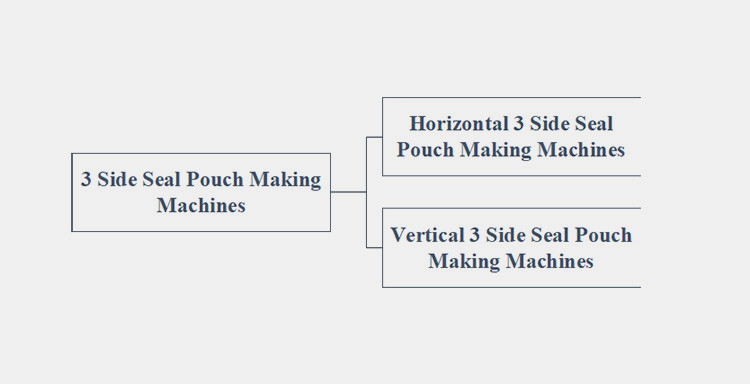

5.How to Classify 3-Side Seal Pouch Making Machines?

3 side seal pouch making machines come in the market with various designs and models. These different machine models process different pouch styles, sizes, and shapes. However, these models under a few basic types of 3-side seal pouch making machines which are discussed below:

Classification based on Configuration

There are two kinds of 3-side seal pouch making machines based on configuration

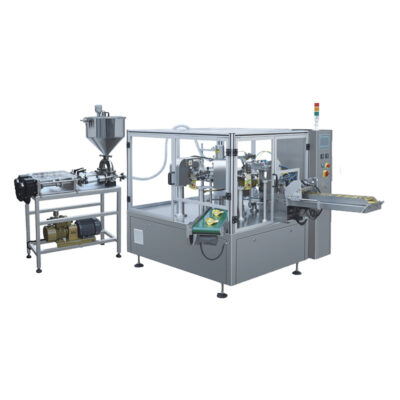

Horizontal 3 Side Seal Pouch Making Machine

In this type of machine configuration, pouch-making, filling, and sealing take place in the horizontal direction. The packaging film moves along the rollers and sealing station horizontally.

By using a horizontal 3-side seal pouch making machine you can make a variety of pouch styles and these machines allow different closure types. This equipment is ideal for packaging heavier objects that can move across the conveyor belt.

Vertical 3 Side Seal Pouch Making Machine

This machine has a vertical configuration. The packaging roll is located at the bottom of the machine and travels upside across the rollers. The formation of pouches usually occurs at the top of the machine while the sealing of pouches happens at the bottom part of the machine.

Vertical 3 side seal pouch making machines can be easily installed in limited spaces due to their smaller footprint.

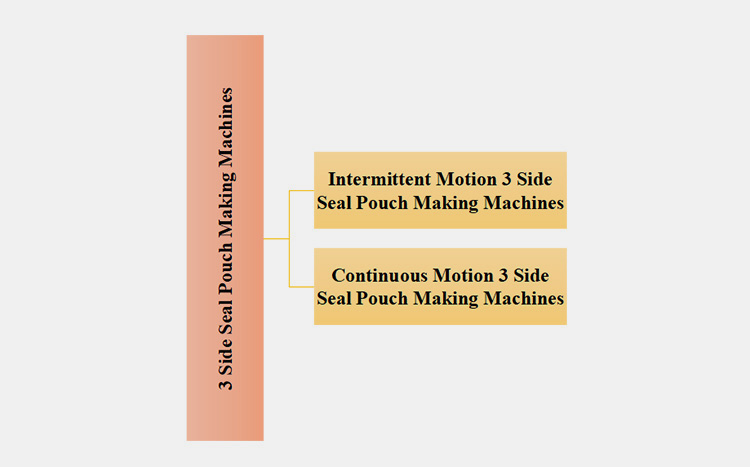

Classification Based on Motion Type

There are generally two classes of 3 side seal pouch making machines based on motion type.

Intermittent Motion 3 Side Seal Pouch Making Machines

These machines start and pause during the pouch making cycle. The movement of packaging film halts during the sealing of the pouch. When the film belt stops moving, at this time sealing jaws glue the film layer together. There is no synchronicity in the movement of film and packaging of products.

The stopping of a packaging operation in these machines aids in the diverse styling of 3 side seal pouches.

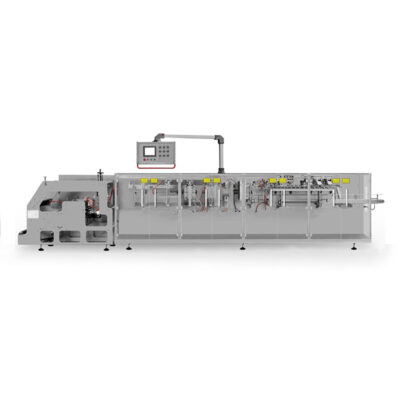

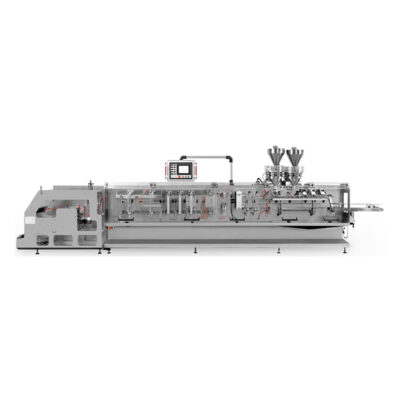

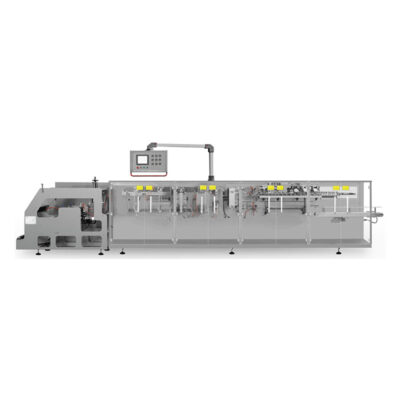

Continuous Motion 3 Side Seal Pouch Making Machines

In this machine type, machine parts are in constant motion. The movement of film and sealing of pouches occurs simultaneously. There is no stop-start cycle in continuous motion 3 side seal pouch making machines. This machine has a higher packaging speed than its intermittent counterpart due to the continuous motion of this equipment type.

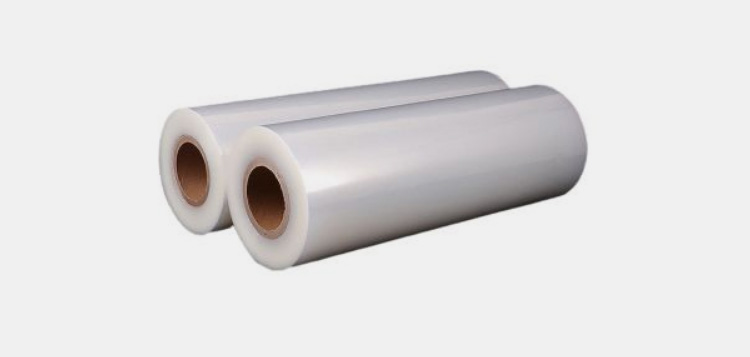

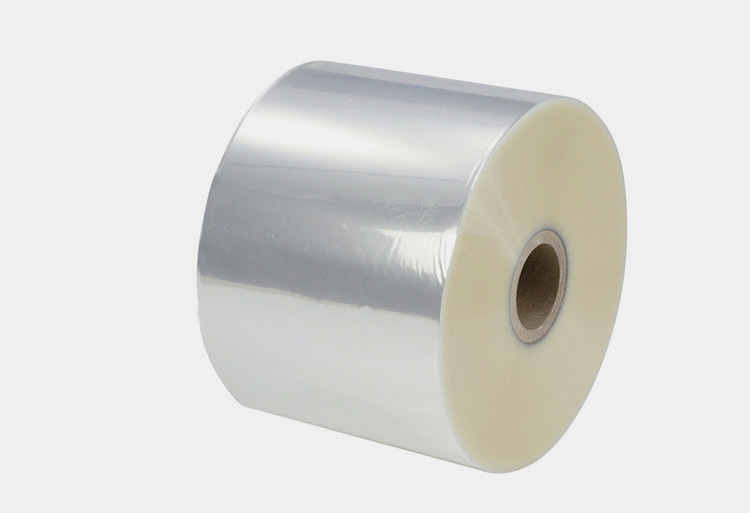

6.What Plastic is Used in 3 Side Seal Pouch Making Machines for Bags?

Plastic is the main material used by these machines for manufacturing bags. These plastic materials come in a variety of forms and characteristics.

A few of these plastics are detailed below:

Poly (ethylene terephthalate) (PET)

It is the most widely used plastic polymer resin belonging to the polyester family. PET is good thermoforming material and is usually used in manufacturing flexible packaging such as 3-side seal pouches. It is a clear, tough, and lighter plastic.

PET can be used indefinitely since it is 100% recyclable and is one of the most sustainable plastic types.

Low-density polyethylene (LDPE)

It is a kind of thermoplastic plastic and is formed by ethylene monomers. It is semitransparent, stretchable, and robust plastic. LDPE is an essential component of packaging films, which are commonly used by 3 side seal pouch making machines. It can be molded into various pouch designs.

3 side seal pouches formed by using LDPE plastic are generally noninflammable and anti-bacterial.

Polyvinyl Chloride (PVC)

Less fossil fuel is consumed for manufacturing PVC than other plastic types. PVC is available in a variety of colors and is routinely used by 3 side seal pouch making machines. About 20% of plastic goods produced across the globe are made of PVC.

It is easily processed, has superior organoleptic characteristics, and has high clarity. Moreover, these plastics are less carbon footprint.

Oriented polypropylene (OPP)

The precursor of OPP is polypropylene. The latter is extended in one direction to form OPP. 3 side seal pouch making machine uses OPP for manufacturing 3-side seal pouches because of its superior tensile strength, transparency, and better printing properties.

Furthermore, it has high-temperature resistance and is the best material for flexible food packaging because of its colorless, tasteless, and non-toxic characteristics.

Ethylene-vinyl alcohol (EVOH)

This plastic is formed by the combination of ethylene and vinyl alcohol. Its superior barrier protection is the reason why EVOH is used by 3-side seal pouch making machines.

EVOH has high puncture resistance and is impermeable to the movement of oils and other organic solvents. It is often used as an interior layer in laminated flexible pouch packaging.

7.What Basic Shapes of Pouches 3 Side Seal Pouch Making Machine Offers?

3 side seal pouch making machines can offer a variety of pouch designs and shapes. But usually, there are two basic shaped pouches manufactured by this equipment.

Rectangular Shape

These pouches have four sides and four edges. The opposite sides of rectangular 3-side seal pouches have the same diameter. Their two sides have a longer length than the other two sides.

Square Shape

The 3-side seal pouch of square shape produced by 3 side seal pouch making machine also has four sides and four edges. However, all the sides of these shaped pouches are of the same length. There is no difference in side length in this shape pouches as seen in rectangular pouches.

Irregular Shapes

Some irregular shapes of 3 side seal pouch include jar shape, bottle shape, fruit shape, animal shape, star shape pouches.

8.What are Different Pouch Styles Processed by the 3-Side Seal Pouch Making Machine?

3 side seal pouch making machine can process different pouch styles such as:

Zipper Pouch

3 side seal pouch making machine can process and fit pouches with double plastic zips interlocks. These zips are resealed by pressing them. These zippers also come as sliding clips and have the same working as zip fasteners. The zippers with clips are simply moved across for opening and closing.

Pouch With Rounded Corners

Normally, these machines make pouches with sharp corners that can be cause of accidental cutting, especially in children. Hence, 3 side seal pouch making machine can be customized to produce pouches with smooth and rounded edges.

Sprout Pouch

These machines can also fix sprouts at the top part of the pouches for convenient dispensing of paste, gel, or viscous liquid products. These sprout pouches are an excellent way for decreasing product spillage and waste. Also, caps of sprout pouches are best for resealing purposes.

Cleat Window Pouches

These pouches with clear windows are highly suitable for product display. Moreover, clear display window features in 3 side seal pouches enhance the product appeal. Customers can easily inspect the size and appearance of products by looking through this transparent window.

Hang Hole Pouches

These are also called euro hole pouches. This pouch has a small hole punctured in its top seal by 3 side seal pouch making machines. These pouches are easily hung on walls or shelves which saves storage space.

Tear Notch Pouches

These pouches have small cutting lines near the end of the seal. Along these lines, pouches are torn for opening. Sometimes, a tear notch is indicated by scissors sign at one end of the top seal.

9.What is the Difference between 3 Side Seal Pouch Making Machine and 3 Side Seal Sachet Machine?

Although both these machines play an essential role in manufacturing flexible packaging, there are some major differences in these packaging equipment. Some of these differences are penned below:

| 3 Side Seal Pouch Making Machine | 3 Side Seal Sachet Machine |

| These machines are mostly available in horizontal conformation. | 3 side seal sachet machines are generally present in a vertical configuration. |

| These types of equipment are used for making 3-side seal pouches in versatile designs such as zipper, hang hole, and rounded corners pouches. | The sachets formed by these machines have a simple tear-notch design. |

| 3-side seal pouch making machine uses multilayered plastic or laminated layers of making 3-side seal pouches. | 3-side seal sachet machines use single thin and flexible materials for forming 3-side seal sachets. |

| These machines design pouches for housing large and many servings of products. | The sachet created by the 3 side seal sachet machines is commonly intended for a single serving. |

| 3-side seal pouch making machine form pouches with high barrier-proof properties. | 3 side seal sachets made by these machines do not have efficient barrier protection. |

10.What is the Difference between 3 Side Seal Pouch Making Machine and Fin Seal Pouch Making Machine?

3 side seal pouch making machines and fin seal pouch making machines are used for making attractive pouches but these machines are quite distinct from each other. Some differences in both these machines include:

| 3 Side Seal Pouch Making Machine | Fin Seal Pouch Making Machine |

| These machines seal the pouches from three sides-top and two sides. | These types of equipment also seal pouches from three sides-top, bottom, and center. |

| The film is folded and then two side seal is made by sealing jaws. Finally, after filling top end is sealed in these machines. | In these machines, interior layers of film are sealed together and then the top layer of film is folded over the interior seal creating a fin-like shape. |

| This machine uses more packaging film. | It uses less packaging film. Therefore, it has a smaller carbon footprint as compared to its counterparts. |

| Packaging formed by this machine has a square or rectangular shape. | Pouches produced by this machine resemble a pillow. |

| These machines make puncture-resistant seals. | The packages formed by these machines are not quite flex resistant. |

11.What General Sizes 3-Side Seal Pouch Making Machine Offers

The general sizes offered by the 3-side seal pouch making machine is usually depended upon the nature, volume, and weight of filling products. The pouches manufactured by these machines can be used for housing single-serving of products or large serving sizes of goods.

The minimum length and width of these pouches is around 50 millimeters while the maximum pouch length is 700 millimeters. The weight of the products that can be accommodated in a 3-side seal pouch is between 2.5 grams to 10 kilograms.

Moreover, these pouches can pack a volume of liquids ranging from 250 milliliters to 2 liters.

12.What are Common Working Defects and Troubleshooting of 3 Side Seal Pouch Making Machine?

Some defects of 3 side seal pouch making machine and their troubleshooting are discussed below:

| Problems | Cause | Remedy |

| Difficulty in Film Unwinding

|

Dirty film rollers

The friction coefficient of packaging film is very large Belt pull pressure is excessive |

Clean dirty film rollers with a dry cloth or brush

Use packaging film with lower friction co-efficient Ease pull belts to decrease their contact pressure. |

| Slippage of Film Pull Belts

|

Lower pressure on film belts.

Dust accumulation on belts. Old or defective pull belts. Inadequate threading of film |

Tighten pull belts to increase their tension.

Wipe the belts to remove debris. Replace the pull belts. Properly thread the film. |

| Film Adherence to Sealing Jaws

|

The temperature of sealing elements is above the threshold temperature

The increased pressure of sealing jaws. Unclean vertical sealing jaws. Misalignment of film that leads to contact of sealant material with the heated plate |

Decrease the temperature of sealing elements.

Reduce the pressure on sealing bars Properly clean cross-sealing jaws. Properly align the film. |

| Weak Seal Integrity

|

Sealing jaws are not aligned with each other

Fluctuation in sealing temperature Poor cleaning of sealing devices |

Properly align sealing jaws so that they are parallel to each other

Keep the temperature steady during sealing Remove dust and debris from sealing devices. |

| Poor Pouch Formation

|

Twisting and folding of the film while transporting film.

Jamming or slippage of film |

Poorly align the film material on the film carriage.

Tighten film belts to maintain film tension. |

| Failure in Pouch Separation or Cutting

|

Defective or blunt cutting blades

Incorrect programming of cutting parameters on HMI |

Replace worn-out cutting blades

Examine cutting settings and adjust them according to the film material. |

Conclusion

3 side seal pouch making machines are versatile, robust, and high-performance devices. These machines are customized in several ways for making diversely styled pouches such as zipper, tear notch, sprout, clear window pouches, etc. They have a simple design, convenient operation, and offer a high return on investments. Hope you have found answers to all your questions by going through this guide. If you have more queries then you can contact our ready-to-serve customer care support

Don't forget to share this post!

Premade Pouch Filling Machine Related Posts

Premade Pouch Filling Machine Related Products

Premade Pouch Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine