18 Important Points About the Capsule Filling Machine: The Ultimate Buying Guide in 2025

With the global impact of the COVID-19 and the development of pharmaceutical manufacturing, pharma packaging industry is also slowly starting to rise. At the same time, the Capsule Filling Machine is very important to the pharma packaging and pharmaceutical Industries.

If you don't know what is a Capsule Filling Machine, then let's figure it out together. Here are some quick questions for you in below:

1.What Is Capsule Filling Machine?

Capsule Filling Machine

The Capsule Filling Machine is also called Capsule Filler or Capsule Fill Machine. A Capsule Filling Machine is a kind of equipment used to fill empty capsules with pharmaceutical ingredients. Industrial Capsule Fillers are applied in large-scale and efficient pharmaceutical production.

In recent years, with the rapid development of the medical and health industry, it has also driven the development of the pharmaceutical machinery industry. Capsule Filling Machine is a commonly used filling equipment in the pharmaceutical industry.

It integrates machine, electricity and gas, and can automatically complete operations such as positioning, separation, filling, locking, and counting. This kind of equipment greatly reduces the manual labor intensity.

Compared with manual operation, the capsule filling machine is highly intelligent, and the production efficiency is significantly improved. The device meets all pharmaceutical hygiene requirements and is widely used in many pharmaceutical companies.

2. How Many Types of Capsule Filling Machines Are There?

There are 3 types of this machine, including Automatic Capsule Filling Machine, Semi-Automatic Capsule Filling Machine, and Manual Capsule Filling Machine. Their structure and function are different.

The Automatic Capsule Filling Machine automatically fills dry powder into capsules. In industry, it is applied to produce large quantities of capsules. They are very durable in nature.

Automatic Capsule Filling Machine

The Semi-Automatic Capsule Filling Machine requires both manual and automatic use. This device has a very simple design and is very easy to be operated. It is both very hygienic and easy for you to use.

Semi-automatic Capsule Filling Machine

The Manual Capsule Filling Machine is mainly used in the small pharmaceutical industry, because this machine produces a small amount of capsules at one time, so it can be done manually. Its advantage is that this device does not require power and can be done manually.

Manual Capsule Filling Machine

3. Which Industries Are Capsule Filling Machines Mostly Applied?

Capsule Filling Machine is suitable for pharmaceutical, chemical, food, light industry, electronics and other industries, the most outstanding performance of this machine is in the pharmaceutical industry, and is widely used in the world. With the impact of global COVID-19, people are more dependent on the pharmaceutical industry, which further promotes the development and progress of Capsule Filling Machines.

Capsule Filling Machine is suitable for small and medium batch production of capsules in small and medium-sized pharmaceutical factories, health care products factories, hospitals and clinics.

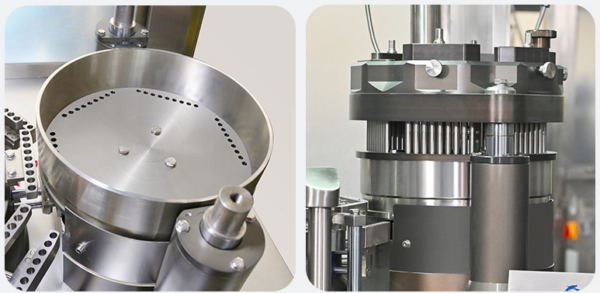

4. What Is the Structure and Composition of Capsule Filling Machine?

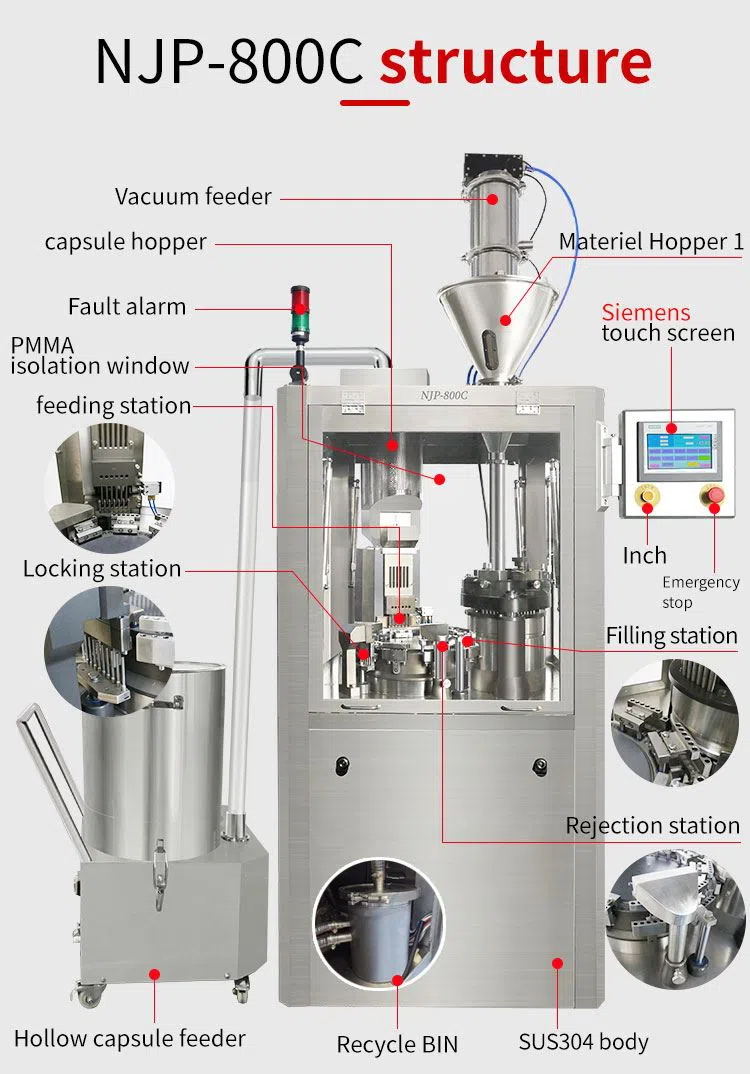

- There are 11 parts of the Automatic Capsule Filling Machine. And we will take the type of NJP-800C for example.

Automatic Capsule Filling Machine

The parts include a vacuum feeder, material hopper 1, capsule hopper, PMMA isolation window, feeding station, locking station, filling station, rejection station, hollow capsule feeder, recycle bin, and SUS304 body. And there are some little parts, including Siemens touch screen with inch and emergency stop, fault alarm.

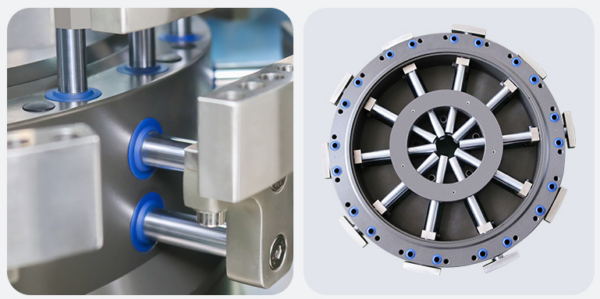

- There are 6 parts of the Semi-Automatic Capsule Filling Machine.

Semi-Automatic Capsule Filling Machine

Pneumatic Horizontal Lock Bag, the lock bag effect is good and does not leak.

Pneumatic horizontal lock bag

Siemens PLC Touch Screen, is easy for you to operate.

PLC Touch Screen

Fully Automatic Capsule Seeding, fast speed and output comparable to that of a fully automatic capsule filling machine.

Fully Automatic Capsule Seeding

Thimble, INnovative Concave Fit Design, the capsule will not be damaged.

Thimble, Innovative Concave Fit Design

Precise Chamfering Design of the capsule disc ensures that the capsule is not lacking in grains.

Precise Chamfering Design

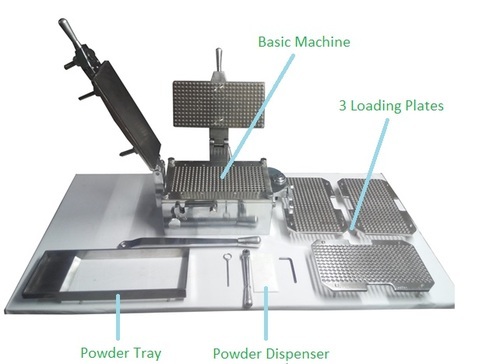

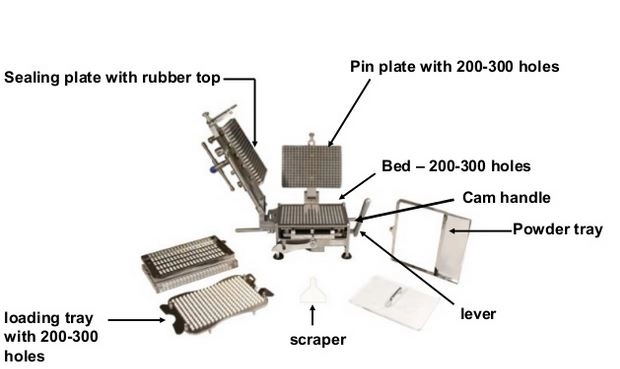

- The Manual Capsule Filling Machine is the most simple one, including a sealing plate with rubber top, pin plate with 200-300 holes, bed with 200-300 holes, cam handle, powder tray, loading tray with 200-300 holes, and a scraper.

Parts of Manual Capsule Filling Machine

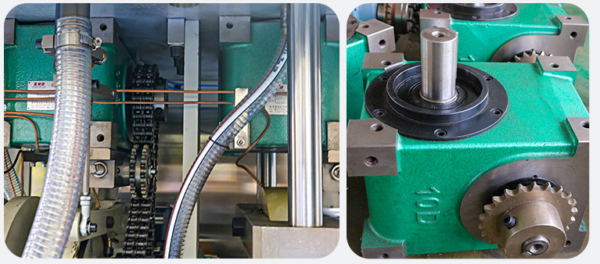

5. What Is the Working Principle of Capsule Filling Machine?

The Capsule Filling Machine generally adopts the form of automatic intermittent rotary motion. It is installed on the rotary table in the center of the worktable. There are 8 short stay times for each rotation.

The rotary table transports the capsules to various workstations around the rotary table, and various operations such as sowing, dividing, filling, rejecting waste, locking, releasing, and cleaning molds are automatically performed at the same time.

6. What Are the Key Features of Capsule Filling Machines?

Here are 15 key features of the Capsule Filling Machine for you to understand:

- Small size, low in energy consumption, simple in changing molds, easy to operate and easy to clean.

- Standardization and serialization: The manufacturing parts can be interchanged universally, and the replacement of molds is convenient and accurate.

- With a high-precision indexer of low vibration, extreme motion working noise can be controlled lower than 70dB, and the dose difference can be controlled within ±3%.

- Electrical components are Germany Siemens, Japan Omron, etc., the control system is safe and reliable.

- The platform adopts 45≠ flat plate surface with hard chrome plating, which is not easy to deform, or rust, and improves hardness;

- The parts indirectly contact with the powder is made of 304 and 316 stainless steel, and Capsule Filling Machine fully meets the requirements of the GMP standard of the pharmaceutical factory;

- Applying different powder collectors according to the needs of users, which can effectively and directly recover 85%--90% of the lost materials, and improve the economic benefits of drug production enterprises.

- With complete functions, the buzzer will alarm when the hopper is empty. When the material bag is nearly empty the machine will automaticlly shut down.

- Pill, granule, tablet filling function, meeting 3 kinds of materials, and meeting the needs of slow-release, controlled-release and tablet medicines packed in the same capsule;

- With the filling function of pellets, granules and tablets installed in the machine according to user requirements.

- There are three kinds of materials that can meet the needs of slow-release, controlled-release and tablet medicines in the same capsule;

- The bottom of the metering disc is equipped with a sealing device, which improves the powder leakage, reduces the wear of the parts, and is more convenient for cleaning.

- There are sideboards around the dosing disc, which can effectively recycle the powder thrown out from the lower plane of the dosing disc through the pipeline for reuse, and reduce the dust on the work surface at the same time;

- Design of avoiding cross-contamination and energy efficiency, redesign the discharging device of the finished capsules, without applying the air compressor, thereby reducing the overall size and noise of the whole machine, avoiding cross-contamination and movement failures caused by air-pressure discharging, and achieving significant energy-saving effects;

7. What Is the Operating Procedure of Capsule Filling Machine?

We will show you the operating procedure of the Capsule Filling Machine with the example of the Manual one below:

Automatic Capsule Filling Machine:

- Use the handwheel to idle the machine clockwise to verify whether the machine runs smoothly and that all parts are synchronized.

- Switch on the power, press the button of the vacuum pump cleaner, and press the main engine start switch. Let the machine idle at low speed for 2 minutes, check whether the vacuum pump cleaner is normal, press the stop button to stop the machine, and prove that the installation is correct.

- Put the needed empty capsules into the container, check whether the powder mixer is fixed, put the powder into the powder hopper, and keep the mixer button in the automatic position.

- Turn on the switch of the dispensing hole, run the machine for 1 minute and then stop, and adjust the filling amount.

- No powder is allowed to add at the beginning of the capsule delivery. During the operation, when the capsules are sent to the turntable and become irregular, check whether the capsule container has enough capsules; if there are capsules that are not locked or damaged which hindered the capsule delivery, you should remove the capsules with tweezers.

- If the horizontal fork cannot push the capsule to the correct position, you should loosen the lock pin nut. When the vertical fork is lowered, you should lock the nut after the capsule is guided into the mold without any difficulty.

- The reason why the waste capsules are rejected is that the capsules have not been separated. It should be checked whether there is debris blocking the mold sleeve, or whether the hollow lock pin is blocked by broken capsules, leading to the failure of the vacuum suction separation action. when this happened, you should remove debris.

- The vacuum value of the instrument installed on the vacuum pump must be kept within the range of 0.02-0.04 Mpa.

- The diameter, length and weight of the powder column loaded into the capsule should be strictly predetermined. If you want to adjust the pressure of the filling quantitative tube, you can adjust the nut.

- Adjusting the height of the powder can change the height and compactness of the powder layer in the powder basin, so that the powder column remains stable.

Semi-Automatic Capsule Filling Machine:

- Check whether the device and its parts are in good condition, and sterilize it according to the relevant regulations. Select and install the required type of capsule delivery assembly, capsule broadcasting series, thimble tray, capsule tray, etc.

- Start the air compressor to the automatic adjustment position, and the empty disk pressure is automatically adjusted between 0.5-0.7 Mpa.

- Turn on the main motor and vacuum pump motor, when the vacuum gauge indicates 320, the capsule tray can be installed, and the operating lever is turned to start the capsule delivery.

- Adjust the capsule counter to the required value in advance, and turn the input selector switch to the electric shock position. During the running and suspending conditions, do not touch the reset button on the counter to avoid damage to the internal parts.

- After the capsule is finished, manually turn the capsule disc for 2-3 circles to make the hollow capsules separate better in the capsule disc. Adjust the cock on the round handle of the vacuum filter properly to maintain a proper vacuum degree, so that the capsules are easy to separate and not easy to be damaged.

- Adjust the selector switch on the control panel to the automatic position, lift or press down the shift lever of the powder disc to rotate the powder disc, and activate the filling button on the panel to turn the filling powder hopper to the proper position.

- Adjusting the filling counter so that all capsules are completely filled. If poor filling happened, you should adjust the counter to solve the problem. During the filling process, do not place your hand or head in the storage hopper at will to avoid bumps.

Manual Capsule Filling Machine:

- Firstly, place the cover sheet on a flat surface, then place the capsule filling sheet on top. Secure it with stainless steel screws. Pour an appropriate amount of capsule top onto the encapsulating sheet.

- Gently tap and shake the capsule filling machine so that the top of the capsule fits into the holes.

- The gap in the sheet is then covered preventing the top of the capsule from overflowing. After filling all the holes, remove the excess top. Finally remove the encapsulating sheet and set the cover sheet with capsules aside.

- Fill the powder into the capsule. After first time filling the capsule, use the tamping tool to compress the powder. Remove the tool, add more powder and compress again.

- Cover the capsule. Place the middle sheet on the capsule-filled sheet and secure it with stainless steel screws. Gently flip the cover and secure it to the bottom.

- After assembling these components, apply sufficient force evenly on the top of the machine. Then flip the entire machine over, applying enough force down. This locks the capsule securely.

8. What Are the Advantages and Importance of Capsule Filling Machine?

Capsule Filling Machines occupy an important position in the entire medical industry and are widely used in medical, commercial, and our life. Let's take a look at their advantages and importance:

- The vacuum suction pipe and the waste removal pipe are designed inside the body, which avoids hardening of the air pipe, breaking, and air leakage, which is convenient for cleaning the work surface and meets the requirements of GMP.

- The original plastic nuts are replaced by stainless steel material, which avoids the breaking of the filling rod; there are few nuts on the table, which is easy to clean and makes the whole machine more beautiful.

- The defective capsules can be automatically removed, and the powder in the defective capsules can be recycled and reused, which greatly increased economic benefits.

- The Capsule Filling Machine is easy to disassemble and clean, and many types of molds can be used from each other. Among them, the 800-type, 1000-type, and, 1200-type molds can be exchanged and used on the same machine to meet the requirements of different production capacities.

- The whole machine is beautiful with fine craftsmanship, simple operation, and very convenient to use. The design of integrating the filling seat and the metering disc improves the filling accuracy of the machine and prolongs the service life.

9. Why Should You Choose Capsule Filling Machine?

- From capturing Capsule Filling Machines market growth, scale, leading enterprise, to save time in entry-level research.

- By pointing out business priorities, can help companies to change your business strategic matters.

- Recent surveys and reports have revealed the importance of the Capsule Filling Machines’market, thereby enabling the entire participants to develop effective long-term strategies.

- Judging by the significant growth in emerging markets, there are more businesses and individuals revising and expanding your business plans in this area.

- By deeply researching the global market trends and outlook, you get a detailed report, at the same time with the help of the market, you can subdivide, price, and distribute the products your needs, which will help your decision-making.

10. How to Choose a Good Capsule Filling Machine?

It is very difficult to choose a suitable Capsule Filling Machine. What kind of things have you considered when choosing a machine? Below we will tell you how to choose a suitable and efficient Capsule Filling Machine.

The first thing you need to consider is definitely the brand. A good brand is very important, which not only represents good quality, service life, reputation and after-sales, but also represents how much cost it can save for you.

The second is the manufacturer. The manufacturer is very important. Now the relevant international manufacturers are including BOSCH, Harro Hofliger, LFA, ACG, IMA, AIPAK, Romaco, Dr. Pharm, and so on.

Remember to consider the production capacity and production parameters of the machine.

We are pleased to recommend you several classic models. They are NJP-200C, NJP-400C, NJP-800C, NJP-3800C, NJP-6000C.

11. What Are the Precautions In the Use of Capsule Filling Machine?

This equipment is a kind of vibrating machine. You should always check the tightening of the screws in each part of the machine. If any screws are loose, you should tighten them in time to prevent machine failure and damage.

The plexiglass parts of the machine (worktable, capsule board) should be protected from direct sunlight, and high temperature. Heavy objects should not be placed on the device, and the capsule board should be placed vertically or flat to avoid deformation and damage.

At the end of each day's work, you should clean up the residual medicine in the mold hole, keep the whole machine clean and hygienic, and avoid rinsing the main engine with water. If the mold on the machine needs to be cleaned, you can loosen the screws and install it again.

For the reducer in the locking machine, the oil should be changed after 24 hours of accumulative use for the first time, and the oil should be changed for the second time after accumulative use of 72 hours. Changing the oil every month thereafter.

12. How to Recycle and Dispose of Defective Empty Capsules from Capsule Filling Machine?

There is a special device on the Capsule Filling Machine called a powder recovery device. This is an improved invention.

The Capsule Filling Machine is to fill the medicine powder in the metering hole on the metering disc into the capsule below it. During the filling process, the medicine powder will be scattered, which will easily cause the medicine powder to be accumulated at the entrance.

After that, it will cause the medicine powder to block the entrance and exit of the tube, which will easily damage the machine and cause waste and loss of resources.

So this device is applied specifically to solve this problem. By recycling the scattered powder, a recovery seat is arranged under the sealing tray.

There is a recycling tube attached to the seat, which is connected to the powder recycling box. With the help of a powder pump inside, the waste powder is recycled into the box, which greatly improved the efficiency of the Capsule Filling Machine.

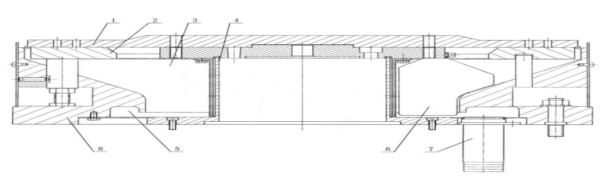

Details below:

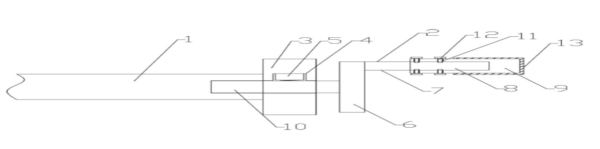

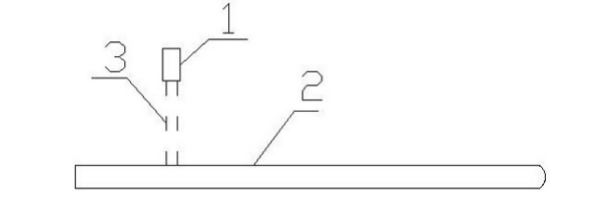

Figure 1

Figure 1: 1-Metering disc, 2-Sealed tray, 3-Powder recycling tube, 4-Rotary shaft, 5-Powder collection tube, 6-Scraper, 7-Recycling tube, 8-Base.

The recycling device includes a base. The shaft mounting hole and a powder recycling tube are designed at the center of the base. The powder recycling tube is equipped with a scraper, and the scraper is connected with the rotating shaft in a drive.

When the powder enters the center of the recycling tube, the scraper in the powder recycling tube loosens the powder and scrapes off the powder adhering to the inner wall of the tube to prevent the powder from accumulating on the inner wall.

The medicine powder recycling tube is in the shape of a funnel, and the lower end of the base is provided with an annular medicine powder collection tube. The lower end of the medicine powder recycling tube is connected with the medicine powder recycling box.

And the scraper should be matched with the inner wall of the powder recycling tube. Through the action of the powder pump, the residual and accumulated powder is recycled into the powder box, which greatly improves the efficiency.

13. What Are the Safety Protection Devices of Capsule Filling Machines?

When the Capsule Filling Machine fails, it is necessary to manually rotate the handwheel for maintenance. The rotary handwheel is an important maintenance accessory, which is used for maintenance, debugging and replacement of filling molds.

When performing a manual crank check, you must be sure that there are no obstacles before performing a trial run. Because the rotating handwheel is a temporary device, this makes the equipment lack of safety protection, thus sometimes causing equipment injury accidents.

The safety protection device of the Capsule Filling Machine can effectively solve the hidden danger and prevent injury accidents during the use of the equipment.

Details below:

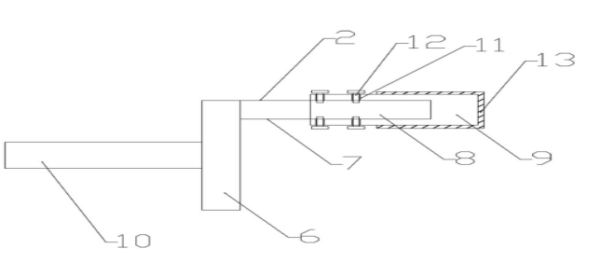

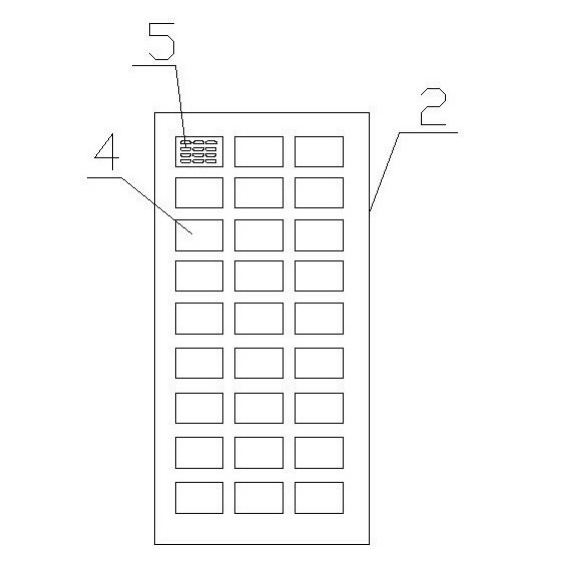

Figure 2

Figure 2: 1-Main motor shaft, 2-Rotary handwheel, 3-Fixing collar, 4-Rectangular groove, 5-Micro switch, 6-Wheel disc, 7-Telescopic handle, 8-Inner cylinder, 9-Outer cylinder, 10-Center shaft, 11-Positioning hole, 12-Positioning post, 13-Slip sleeve.

The safety protection device of the Capsule Filling Machine includes the main motor shaft and the rotary handwheel. The outer end of the main motor shaft is provided with a fixing collar.

The inner wall of the fixing collar is provided with a rectangular groove. A micro switch is arranged in a rectangular slot. The micro switch is electrically connected to the contactor of the Capsule Filling Machine.

The rotary handwheel includes a wheel disc and a telescopic handle. The end of the main motor shaft is provided with a groove.

A bump that matches the groove is arranged on the central axis of the wheel disc. The central shaft of the wheel disc is installed in the main motor shaft through grooves and bumps.

Details below:

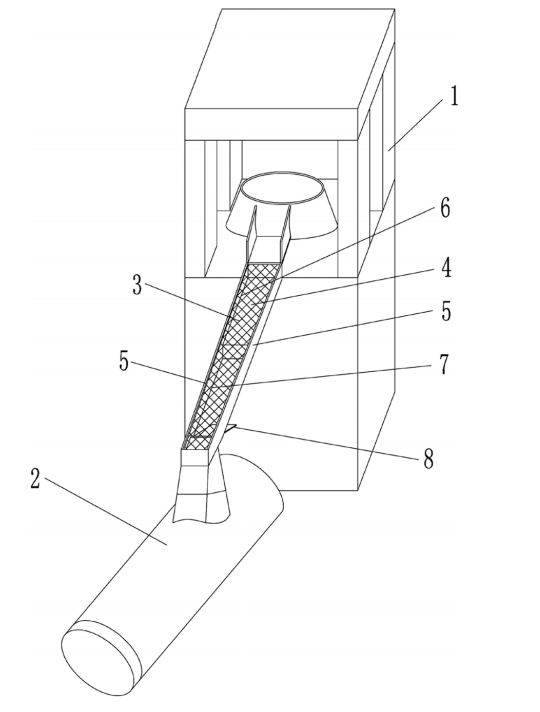

Figure 3

Figure 3: A side view of the rotary handwheel

The telescopic handle includes an inner cylinder and an outer cylinder which are nested with each other. The inner cylinder and the outer cylinder are evenly provided with positioning holes.

A positioning post is arranged in the positioning hole, and the outer cylinder is installed outside the inner cylinder through the positioning post.

The collar is fixedly installed on the frame of the Capsule Filling Machine. The inner wall of the fixed collar is movably connected with the main motor shaft through a bearing.

The groove is a hexagonal prism groove, and the bump is a hexagonal prism matched with the hexagonal prism groove.

The inner wall of the positioning hole is provided with an inner thread, and the outer wall of the positioning post is provided with an outer thread matching the inner thread. The telescopic handwheel is fitted with a anti-slip sleeve.

The safety protection device of the Capsule Filling Machine has a simple structure, and is convenient for you to use with good effects. This device can effectively solve the unsafe hidden danger of Capsule Filling Machine.

By arranging a micro switch in the motor shaft, when the rotary handwheel is in contact with the micro switch, the Capsule Filling Machine will stop working, which can effectively prevent the rotary handwheel from rotating with the motor shaft and prevent accidents and injuries during the use of the equipment. That is suitable for application in various types of Capsule Filling Machines.

14. How to Connect the Capsule Filling Machine to the Capsule Polishing Machine?

Capsule Polishing Machine

During the production of capsule medicine, the medicine needs to be filled into the capsule shell through Capsule Filling Machine. The filled capsules are sent to a capsule polishing machine for polishing.

However, in the production process, the capsules in the polishing machine are also mixed with many drug powders. These drug powders and capsules are sent into the capsule polishing machine together, which affects the normal operation of the capsule polishing machine.

Capsule Polishing Machine

Therefore, this device is used to connect the Capsule Filling Machine with the capsule polishing machine. This connecting device can effectively filter out the drug powder mixed in the capsule.

This kind of device can not only effectively filter the residual drug powder to avoid affecting the capsule polishing operation, but also remove the drug powder in time when the material leaves the Capsule Filling Machine.

At this point, most of the residual drug powder has already been filtered before it contacts the capsule.

Details below:

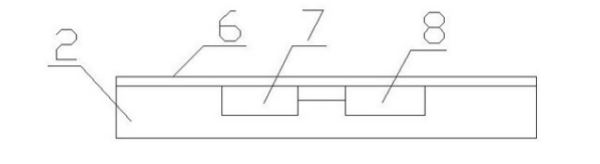

Figure 4

Figure 4: 1- Capsule Filling Machine, 2- Polishing machine, 3- Bottom plate, 4- Leakage hole, 5- Side plate, 6- Sinking tank, 7- Blanking port, 8- Material guide plate

The components in this device are the bottom plate, the leakage hole, the side plate, the sinking tank, the blanking port and the material guide plate.

The material from the Capsule Filling Machine (including capsules and drug powder) slides onto the bottom plate.

Since the size of the leakage hole is smaller than the size of the capsule, the drug powder is filtered when sliding into the leakage hole.

The capsule continues to slide down, eventually sliding into the polisher from the bottom plate. Thereby, effectively filtering out the drug powder mixed in the capsule is realized.

Side plates are respectively arranged on both sides of the bottom plate to prevent the capsules from leaking from both sides.

Leakage holes are evenly arranged on the bottom plate, which can achieve the best effect of removing drug powder.

A sinking tank is arranged below the leakage hole, and the upper edge of the sinking tank is connected to the bottom plate.

The connection line between the sinking tank and the bottom plate is located outside all leakage holes. The bottom of the sinking tank is provided with a blanking port.

In this way, the powder leaking from the leakage hole can enter the sinking tank and flow out from the blanking port, which is beneficial to the collection and recycling of the powder.

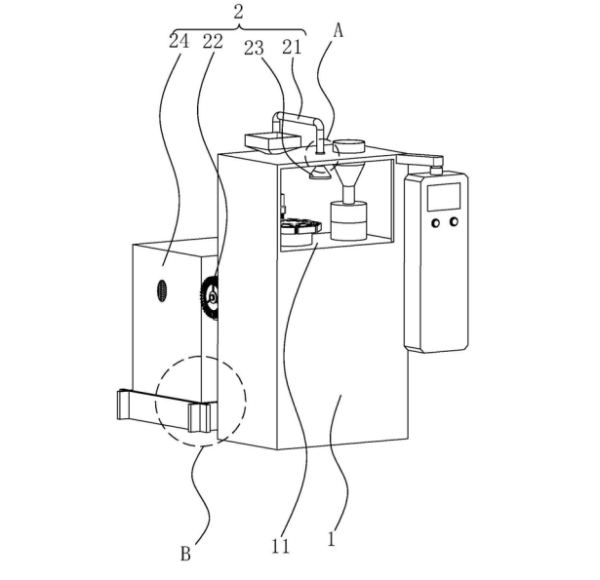

15. What Is the Dust Removal Equipment of Capsule Filling Machine?

Dust Removal Equipment

This device is suitable for automatic hard Capsule Filling Machine and belongs to the field of pharmaceutical processing.

The device includes a body, and the body includes a worktable. A dust removal device is arranged above the work table. The dust removal device includes a dust removal pipe and a fan.

One end of the dust removal pipe is arranged above the worktable. The other end of the dust removal pipe is fixed and connected to the fan. This device has the effect of improving product quality.

Details below:

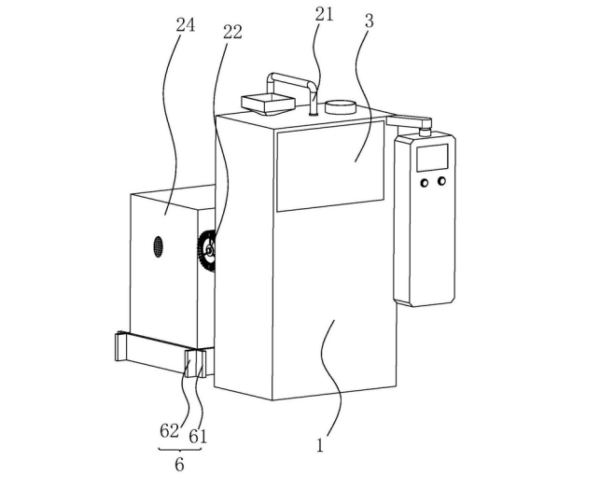

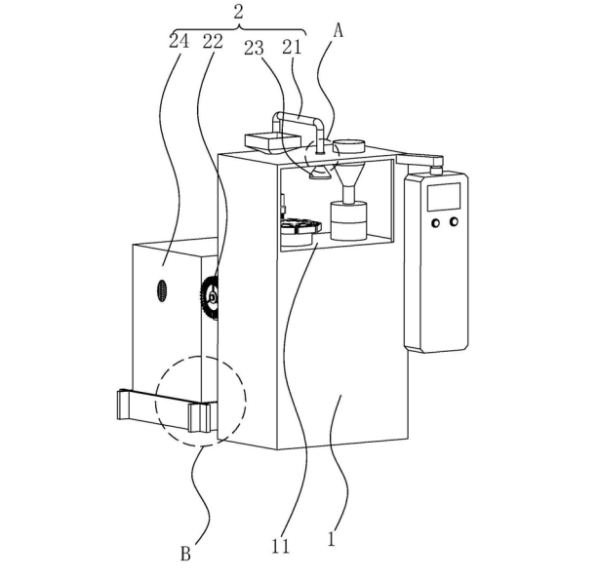

Figure 5

Figure 5: 1-Body; 3-Sealing plate; 21-Dust removal pipe; 22-Fan; 24-Dust removal box; 6-Limit assembly; 61-Limit plate; 62-Plug board.

This device also includes a dust removal device and a dust hood. The dust hood is arranged above the worktable, and the dust hood is fixedly connected to the dust pipe.

Wherein, the dust removal device further includes a dust removal box, and the dust removal box is connected to the fan.

A sealing plate is arranged around the work table. The dust removal pipe is inserted into the sealing plate.

A sealing ring is fixedly arranged on the circumferential surface of the dust removal pipe in contact with the sealing pipe.

The bottom of the dust removal box is provided with rotatable rollers. The dust removal box is set on the ground.

There is limited assembly on the ground. The limit assembly includes a limit plate.

The limit plate abuts the edge of the dust removal box. The limit assembly also includes a plug-in board.

The insert plate is perpendicular to the limit plate, and the insert plate is arranged in the limit plate and connected to the edge of the dust removal box.

Details below:

Figure 6

Figure 6: 1-Body; 2-Dust removal device; 21-Dust removal pipe; 22-Fan; 23-Dust hood; 24-Dust removal box; 11-Worktable.

By using this device, when the Capsule Filling Machine starts to fill capsules, the fan is turned on, and the wind of the fan enters the top of the worktable from the dust removal pipe.

This will absorb the dust generated during the processing of the worktable. The dust content in the space above the table is then reduced.

Thereby, the probability that the dust generated in the processing affects the quality of the medicine will be reduced, thus improving the product quality of the medicine.

Through this device, the dust removal box and the fan are connected.

When the fan sucks the dust from the top of the worktable to the outside of the worktable, the fan transports the dust from the suction place to the inside of the dust removal box.

And the dust is stored, and then the probability of dust escaping from the dust collection pipe is reduced.

At the same time, it is convenient for the staff to recycle the sucked dust, which improves the convenience of use.

Details below:

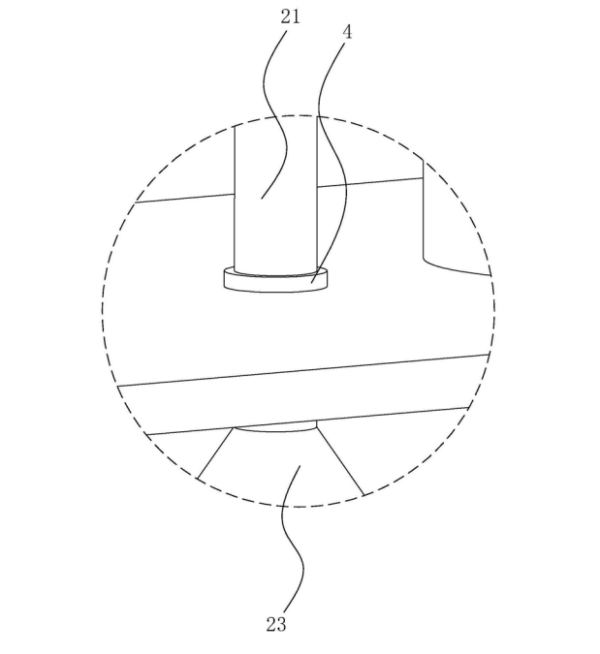

Figure 7

Figure 7: 4-Sealing ring; 21-Dust removal pipe; 23-Dust hood.

By arranging a sealing plate on the body, the sealing plate isolates the space where the worktable is located from the external space.

This reduces the probability of dust escaping from the space near the worktable to the outer space of the machine during processing.

Therefore, the dust removal device can completely remove the dust generated during the processing of the worktable, thereby improving the removal efficiency.

At the same time, the pollution to the working environment after the dust escapes from the worktable is reduced. This is good for the environment and protects the health of workers.

The sealing ring has a sealing effect on the connection between the dust removal pipe and the sealing plate.

This reduces the probability of dust escaping from the gap when the gap between the dust removal pipe and the sealing plate is too large.

It is convenient for the dust removal device to absorb the dust in the space above the worktable. At the same time, the probability of dust contained in the outer space of the body is also reduced, which is beneficial to human health and environmental protection.

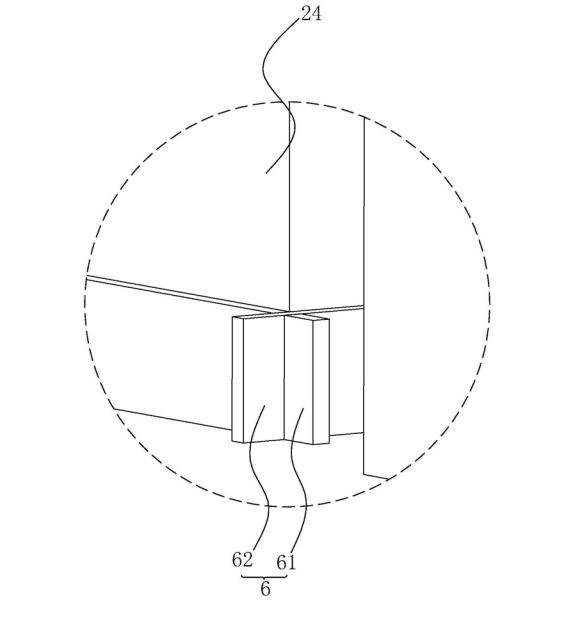

Details below:

Figure 8

Figure 8: 24-Dust removal box; 6-Limit assembly; 61-Limit board; 62-Plug board.

The roller reduces the friction between the dust removal box and the ground, thereby facilitating the movement of the dust removal box on the ground and improving the convenience of moving the dust box.

The limit plate restricts the dust removal box itself, reduces the probability of the dust removal box moving due to the vibration of the fan during use, and improves the use stability of the dust box.

The plug board is set on the limit plate. The insert plate is matched with the limit plate, and is clamped from the dust box in four directions.

Therefore, the movement of the dust removal box is restricted on the plane, the probability of the dust removal pipe falling off from the dust removal box during the movement of the dust removal box is reduced, and the use stability is improved.

Details below:

Figure 9

Figure 9: 1-Body; 3-sealing plate; 5-Roller; 22-Fan; 61-Limiting plate; 62-Plug board.

16. How to Sort the Defective Capsules From Capsule Filling Machine?

After the drug capsule is filled, you need to test whether the capsule is completely filled or not. Only when the capsules are fully filled that they are qualified products.

Due to the automatic filling process, the filling of the capsule board may not be completed. This will result in defective products. So after filling, you need to remove the defective product. Existing Capsule Filling Machines can fully meet your requirements.

This device is called a defective sorting device. This device includes: conveyor belt, detection device, and capsule board.

Details below:

Figure 10

Figure 10: 1-Detective device, 2-Conveyor belt, 3-Vertical laser beam.

There is a detective device above the conveyor belt. The detective device is vertically connected to the conveyor belt. The conveyor belt is provided with an array of light-emitting modules. The capsule board is correspondingly placed on the light-emitting module.

Details below:

Figure 11

Figure 11: 2-Conveyor belt, 4-Light-emitting module, 5-Capsule board.

The light-emitting module includes a photosensitive module, a control switch, and a wireless receiver. These photosensitive modules, wireless receivers, and control switches are connected in sequence, and all are controlled by the central control system through the wireless receivers.

Details below:

Figure 12

Figure 12: 2-Conveyor belt, 6-Photosensitive module, 7-Wireless receiver, 8-Control switch.

This new type of device uses the detective system to illuminate the capsule board, which avoids the drawbacks of manual identification and greatly improves the production efficiency.

17. What Does the Model Number of the Capsule Filling Machine Mean?

Each brand has its different models of machines. But the model number of each machine is made with a different combination of numbers and letters. These letters and numbers all represent different meanings, which are used to distinguish the different performances and work of the machine. Just like everyone has their own name. Now let us take the model NJP-800c as an example.

NJP-800C

The NJP-800c is a kind of automatic closed filling equipment for intermittent operation of porous plug metering. It can automatically complete two or more processes such as sowing, dividing, filling, rejecting waste, locking, and discharging granules from finished products.

And it has the advantages of reliable positioning, accurate loading and high yield. It is suitable for automatic filling of powder and pellet capsule medicines. The machine has two types: ordinary type and man-machine interface improved type.

The improved model is equipped with a touch screen control, PLC programmable controller, intelligent module and optical fiber detection on the basis of ordinary models. It has the characteristics of convenient and intuitive operation. Among them, the important components are imported abroad with a high degree of automation.

18. What Are the Safety Responsibilities of Capsule Filling Staff?

The staff should dress according to the regulations before entering the site. After entering the site, the workshop and equipment should be cleaned and sanitized, and all preparations before operation should be done well.

Receive materials and capsule shells according to the specified procedures according to production instructions.

Capsule filling should be carried out in strict accordance with the process regulations and standard operating procedures for capsule filling.

Strictly check the difference in capsule filling volume and the situation of locking capsules according to the specified time to ensure product quality.

After the capsule is filled, polishing and waxing it according to the regulations, and checking the appearance quality, and pick out the unqualified products.

After the production is completed, the materials shall be handed over according to the regulations, and the remaining materials shall be returned to the intermediate station according to the regulations.

Filling in the records carefully as required.

It is strictly forbidden to leave the post and join another post during the work period, and do not do anything unrelated to the work of the post.

When the work is over or the varieties are changed, the site should be cleared strictly according to the SOP for the position. After passing the inspection by the quality supervisor, a sign should be posted.

Always check the operation of the equipment, pay attention to the maintenance of the equipment, and report any faults found during the operation.

Conclusion:

The input and output of the Capsule Filling Machine are proportional, so more and more institutions and governments have begun to take a fancy to the market for this kind of machine. Capsule Filling Machine is really important in our life. Therefore, it is also very important for you to understand the relevant knowledge in this area. If there is anything else you need to consult or do not understand, please feel free to contact us.

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours