10 Reasons Why You Should Own An AIPAK Capsule Filling Machine

Capsule filling machines can be widely used in the pharmaceutical and health care products industries. What are your thoughts when choosing a partner brand for capsule filling machines?

AIPAK Capsule Filling Machine

Will you choose AIPAK if you are considering different capsule filling machine brands? Have you considered what are the advantages and disadvantages of different capsule filling machines? Have you learned about the advantages and features of AIPAK capsule filling machine?

This post will offer you the most complete benefits of AIPAK capsule filling machine and the 10 reasons why you should own an AIPAK capsule filling machine. Let's follow up now!

1.Multiple Capsule Filling Machine Types For Your Choice

AIPAK Capsule Filling Machine Types

One of the biggest advantage you may have for choosing AIPAK capsule filling machine is that there are multiple capsule filling machine types for your choice. AIPAK capsule filling machine both include semi-automatic and fully automatic type.

AIPAK Semi-automatic Capsule Filling Machine

AIPAK Semi-automatic Capsule Filling Machine

AIPAK semi-automatic capsule filling machine is suitable for filling capsules of various sizes of powders, pills and granules. Equipped with an electronic automatic counting device, speed regulating device, etc.,

The capsule filling machine can complete steps such as capsule placement, separation, filling, and locking, etc. This machine can replace your manual operations and improve production efficiency.

AIPAK Automatic Capsule Filling Machine

AIPAK Automatic Capsule Filling Machine

AIPAK automatic capsule filling machine can automatically complete the entire process of feeding materials, removing waste capsules, cutting capsules, and cleaning molds. With advantages of high precision and low noise, it adopts automatic control, stepless speed regulation, and digital display to facilitate your operation.

This capsule filling machine machine is equipped with a safety protection device that will automatically stop after the material is used up to ensure the safety of you and the machine.

2.Wide Application

AIPAK capsule filling machine is the most basic equipment for filling hollow capsules in the pharmaceutical industry. There are wide application for its use. The industries it can be used in include:

Pharmaceutical Industry

Pharmaceutical Industry-sourced: rousselot

AIPAK capsule filling machine can accurately fill a certain dose of drug powder and granules into empty capsule shells. These powders and granules will be sold as medicines or pills. The capsule types include enteric capsules, gelatin capsules, hypromellose capsules, modified release capsules, inhalation capsules.

Health Supplement Industry

Health Supplement Industry-sourced: verywellfit

There are plenty of health supplements are filled and sealed with the AIPAK capsule filling machine. The common supplements include vitamins such as multivitamins, minerals like calcium, magnesium, and iron, botanicals or herbs such as echinacea and ginger, botanical compounds including caffeine, amino acids like tryptophan.

Cosmetics Industry

Cosmetics Industry-sourced: biocrown

Plenty of skincare capsules are produced by AIPAK capsule filling machine, including skin oil capsules, fish oil capsules, serum capsules, hair oil capsules, mask lotion capsules, makeup capsules, lip lotion capsules, nail gel capsules, skin beauty capsules, etc.

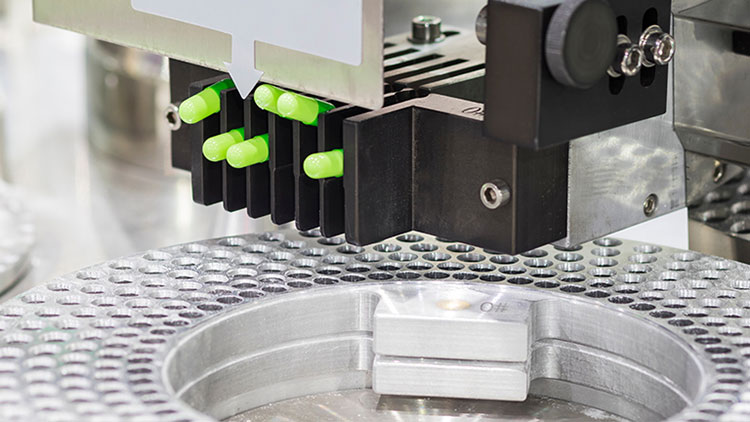

3.High Filling Accuracy

High Filling Accuracy-sourced: fplushealthcare

Importance of Owning An Capsule Filling Machine With High Filling Accuracy

It is very important for you to have a high-precision capsule filling machine. The lack of precision in capsule filling will cause the capsule filling dose to be inaccurate, and it is easy to miss the filling or fill it too much, resulting in too many waste capsules later, affecting efficiency and increasing costs.

High Filling Accuracy That AIPAK Capsule Filling Machine Brings You

Capsule High Filling Accuracy-sourced: promnicesk

The capsule filling machine from AIPAK measures and fills the powder and granule dosage very accurately, and the dosage of filling powder and granule can be adjusted at any time during your operation. The machine utilizes a tamping system that allows each tamping station to be individually adjusted for precise weight control.

The capsule filling machine has an adjustable gap between the metering disc and the pressure plate, which ensures minimal powder spillage. This ensures your powder filling accuracy. The capsule filling machine operates very smoothly, is simple to operate, easy to maintain and clean, and has low noise.

4.High Production Capacity

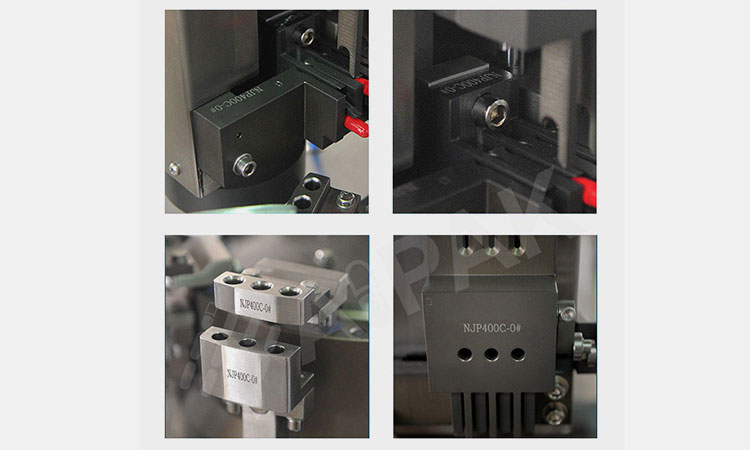

Applicable For Volumetric Capsule Sizes

Volumetric Size Numbers For Capsules-sourced: expresspharma

AIPAK capsule filling machine has different types and models, ranging from semi-automatic to fully automatic types with plenty models of CGN and NJP for your choice. It is capable of filling empty gelatin capsule doses with the highest precision and is suitable for hard gelatin capsules in sizes 000, 00, 0, 1, 2, 3, 4 and 5.

High Production Capacity and Output

High Production Capacity and Output

The capsule filling machine production capacity from semi-automatic to fully automatic ranges from 25,000 to 46800 capsules per hours with high output and efficiency. AIPAK capsule filling machine is designed to increase productivity and maximize your production capacity.

According to your own needs, you can choose a capsule filling machine that suits your production scale, which can bring you high production capacity.

5.Cost-effectiveness

Cost-effectiveness-sourced: Monday

Cost-effectiveness is one of the key benefits of using a AIPAK capsule filling machine in your pharmaceutical production and health supplement industry. It provides you with a cost-effective solution without compromising the quality and performance of your production.

AIPAK Capsule Filling Machine With High Efficiency

AIPAK is able to provide the pharmaceutical industry with the high quality and cost-effectiveness capsule filling machines it requires. With one of the most advanced manufacturing facilities, this equipment offers excellent processability, durability and high productivity. It can bring you maximum cost-effectiveness.

While optimizing production efficiency, the AIPAK capsule filling machine minimizes material waste, ensuring long-term reliability and reduce maintenance costs. Because all high-quality materials are used, it can save you costs while ensuring production.

6.Flexibility And Efficiency

AIPAK Capsule Filling Machine With High Flexibility and Efficiency

Modular Design For Your Flexibility

Modular Design

AIPAK capsule filling machine has a modular, flexible configuration and design that allows you customization and flexibility to meet your specific production requirements. It can bring you maximum flexibility and efficiency.

High-quality Configuration For Your Efficiency

Productivity is a key factor in achieving your effectiveness. The high-quality equipment and models provided by AIPAK can ensure your fast and continuous production of capsule filling in reducing labor costs and increasing overall productivity.

Capsule filling machine from AIPAK is able to handle a variety of capsule sizes and formulations to meet your different production needs while maintaining efficient throughput. It is suitable for all types of production requirements in the pharmaceutical, and chemical industries with low-maintenance.

7.Easy To Operate and Maintain

Intuitive Interface For Easy Operation

While taking into account high economic benefits and user-friendliness, it is also very important to provide you with a good operation and maintenance experience. The AIPAK capsule filling machine prioritizes an intuitive interface and simplified workflow, which allows you to quickly master the operation of the machine without extensive training.

Simplified Workflow For Simple Maintain

Working Process Of AIPAK Capsule Filling Machine

In addition to being easy to operate and maintain, AIPAK capsule filling machine can also provide you with comprehensive documentation, training materials and quick-response technical support, which can maximize the life of your machine. It adopts a fully automated process to facilitate your operation.

The AIPAK capsule filling machine adopts a closed batching system, which can ensure that the frequency of cleaning is greatly reduced with the help of vacuuming, thus facilitating your later maintenance. Equipped with state-of-the-art manufacturing facilities and superior quality, it is able to provide you with a wide range of medical application scenarios.

8.Time Saving And Less Labor Work

Saving Your Time

Saving Your Time-sourced: celayix

In addition to achieving efficient and precise capsule filling, the AIPAK capsule filling machine can minimize operator training, reducing production costs and waste. It can save you more time, which is also the goal of the AIPAK capsule filling machine.

Less Labor Work

Less Labor Work-sourced: pngitem

With a fully automated process, the AIPAK capsule filling machine ensures that no large number of workers are concentrated on one specific operation. Not only does it save you a lot of time, but it also reduces a lot of labor.

In terms of human design, the AIPAK capsule filling machine has a reasonable design structure, easy disassembly and assembly, simple cleaning, and interchangeability of various molds. Therefore, convenient maintenance and inspection in the later stage of the equipment can also save manpower.

9.Technical Service Support

Providing You Professional Technical Team

Professional Technical Team-sourced: optimaproducts

After owning the AIPAK capsule filling machine, how to install, debug, program settings, correct use, maintenance and overhaul are all very important procedures. AIPAK can provide you with a professional technical team and offer you technical service support, maintaining your training, improving the technical capabilities.

Offer You Technical Service Support

Technical Service Support-sourced: qualicaps

While providing you with excellent capsule filling technology and equipment, AIPAK also spreads advanced technical support and maintenance services. In order to be committed to customers and your satisfaction, AIPAK technical team can provide you with professional technical services anytime and anywhere to help you.

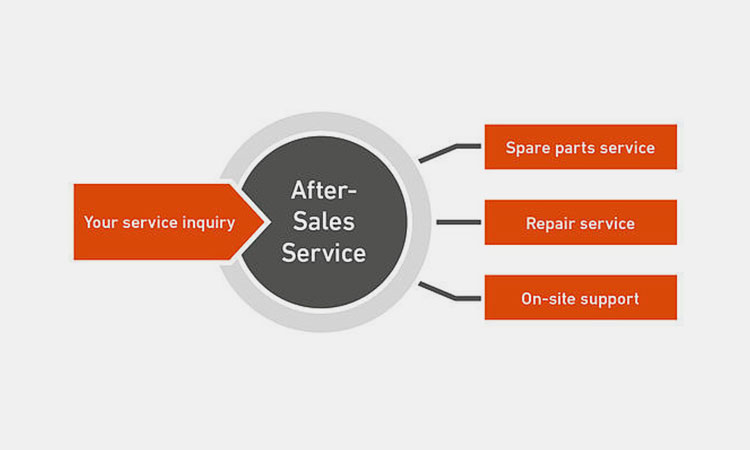

10.Good After-sales Service

Good After-sales Service-sourced: cjdropshipping

In addition to providing you with one-stop capsule filling solutions, AIPAK can also continuously maintain your after-sales service, which is AIPAK commitment to you. Owning an AIPAK capsule filling machine not only provides you with an excellent machine, but also provides you with excellent after-sales service.

Professional after-sales services include:

- One-stop or customized solutions according to your needs;

- Ordered goods are delivered within the stipulated time;

- Reliable raw materials and raw material suppliers, etc.;

- Quality guarantee and efficiency of the capsule filling machine, and provide free replacement and update of worn parts;

- Remote technical support and on-site installation and debugging services;

- Staff training;

- Lifetime warranty, etc.;

Maintaining industry standards to meet customer needs is AIPAK lifelong pursuit. Choosing AIPAK and AIPAK capsule filling machine is your most right choice.

Conclusion

After reading through this "10 Reasons Why You Should Own An AIPAK Capsule Filling Machine", you may know how professional we are. AIPAK can offer you the best machine quality and the perfect service support. About getting one AIPAK capsule filling machine now? Do not wait and come to us now!

Don't forget to share this post!

Capsule Filling Machine Related Posts

Capsule Filling Machine Related Products

Capsule Filling Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine