10 Questions To Answer Before Requesting A Tablet Press Machine

Planning to buy a tablet press machine!

Are you buying it for the first time? Do you want to know what questions your manufacturer would ask?

Buying anything for the first time could be troublesome without proper guidance. Today, most manufacturing companies prefer online meetings or one-to-one discussions to offer you a variety of available options.

10 Questions to Answer Before Requesting a Tablet Press Machine is all about important factors that a manufacturer expects from you. You must keep these helpful tips in mind to avail the right options for your production line.

Table of Contents

Ⅰ.What is your production material?

Perhaps the most common question to answer, it almost seems very simple too. You know your production material inside and out, but the machine supplier likely does not. Moreover, your product and properties make all the difference when it comes to choosing a tablet press machine.

What type of production material do you run?

Powders

The powder is an essential unit behind every pharmaceutical, food, nutraceutical, chemical, etc formulation. Because it promotes cohesiveness (adhesion) and helps the active ingredient to hold in a tablet form.

Granules

Is your required material in granules form? Granules help you to achieve desired tablet appearance and avoid dustiness. Moreover, it enhances the physical and chemical properties of your product too.

Herbs

This material is frequently used in the preparation of nutraceutical and herbal tablets. Due to its sticky nature and sensitivity, this is very technical to make tablet formulations using herbal powders, that’s why various formulations are available in capsule form.

Vitamins

As you know, preparation of vitamin tablets or supplements require special treatment in order to sustain its potency. That’s why your manufacturer would be especially concerned with it. Because pharmaceutical and nutritional products may be affected by heat exposure during compression (may melt or leave sticky deposits). Therefore, you will be provided with proper guidelines and bespoke equipment e.g. low friction compression rollers etc.

II.What is your tablet used for?

| Chewable Tablets |

They are rapidly dissolved and absorbed in the stomach upon ingestion offering a fast onset of action. These tablets come in various flavors and colors. |

| Orally Disintegrating Tablets

|

These tablets tend to dissolve on the tongue where they go directly into the bloodstream. They also work the fastest. For instance, anti-nausea and migraine medications. |

| Sublingual Tablets

|

These tablets are placed below the tongue for fast absorption. They are mostly used to treat ailments where you require rapid action such as nitro-glycerine antihypertensive medication. |

| Effervescent Tablets |  Effervescent tablets are dissolvable tablets that disintegrate rapidly when you drop them into the water or juice. The ingredients of effervescent tablets are designed in such a way that allows evenly dispersion and you can drink it like a standard drink. |

Every good vendor always seeks to know the applications of your production sector. Such as:

| Pharmacy |  Indeed, pharmacy comes into one’s mind when thinking about tablet press. Because the tablet press is a particular option for making various shapes and sizes of tablets frequently required in the pharmaceutical sector. |

| Healthcare |

In the healthcare industry, tablet press provides you with pressing milk tablets, vitamin press or nutraceutical tablets, dietary tablets, and other related products. |

| Food

|

A tablet press is ideally suited for food and confectionary uses offering a high output with ultra-hygienic treatment, e.g. biscuits, coffee beans, etc., |

| Chemical |

A tablet press machine is used for pressing chemical powders, granules, or other formulations. For instance, pH tablets, camphor, etc., |

| Agricultural |

This is a vast field that frequently requires specialized tablets to improve crops or protects them against the invasion of unwanted microbes or pesticides. |

| Pet Food |

The veterinary production line is associated with the preparation of antibiotics, health boosters, or seasonal allergic preparations in the form of the tablet dosage form. |

| Military |

The tablet press machine is suitable for the preparation of specialized compressed biscuits used for an army or civilian foods. |

III.How about your material fluxility?

It is important to study fluxility of your product. Material fluxility is extremely significant for a robust tablet press machine to get a high-performance compression. Because it gives a particular shape and independent particle size distribution.

A key to free-flowing granules is that each particle must be near-spherical in the structure; whereas irregular shape may lead to cause high friction and ultimately poor flow.

Your machine supplier would like to determine the type of material you use. Because granulating equipment such as a high shear mixer or fluid bed granulator can be added to the production line to improve the flow properties of the material.

Moreover, you can measure good fluxility by measuring:

- Angle Of Repose with Rheometers.

- Settlement test (Hausner Index, Dynamic Tests by Settlement).

IV.Is your material corrosive?

Informing about the manufacturing process and material’s properties can significantly influence its impact on the machine’s material. Moreover, if your material is harsh or corrosive, then the stainless steel machine is the best option used around the world due to its excellent anti-corrosive effects.

Are you using corrosive material in your production line?

You can specifically emphasize in case of using hydrochloric acid, chloride, and acetic acid. Alkali salts, potassium hydroxide, etc in your formulation.

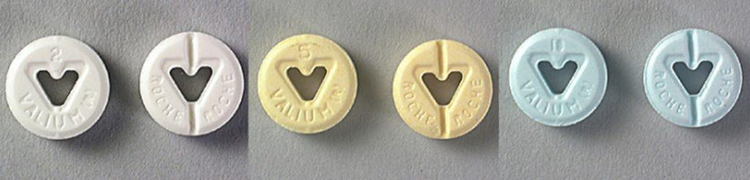

V.What is your required tablet's shape and size?

The size of the tablet can range from a tiny sphere pack to a large bulky rod. When it comes to assessing tablet design, smaller is usually better (in terms of swallowing) but hard to handle (in terms of manufacturing). Your manufacturer would ask about specific dimensions to offer you the tooling require for your system.

The buyer must monitor and evaluate tablet dimension, size, and shapes before quotation.

Size

You can measure the thickness of the tablet by using a vernier caliper, or thickness gauge. This is essential to know to get the required die for a production system.

- Usually, tablet sizes range from a few millimeters (mm) to about a centimeter (cm). For e.g mini-tablets are commonly available with diameters≤ 3 mmwhile the median length of various tablet dosages is >20 mm; longer than a standard US penny with a diameter of 05 mm.

- If you are preparing antibiotics, then the estimated range is from 8 to 25mm with a median length of 18mm.

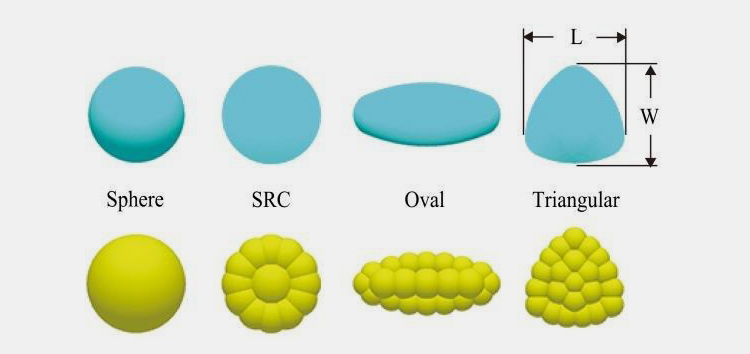

Shape

Well, tablets come in various shapes e.g., spherical, oval, oblong, triangular, etc. For this, different types of punches are used such as shallow concave, standard concave, deep concave, extra deep, etc.

So what shape do you prefer?

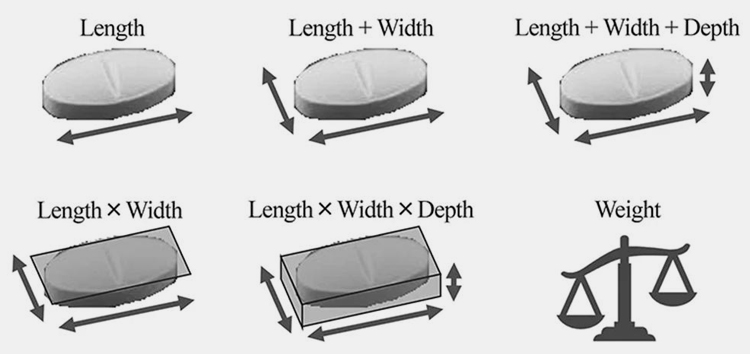

Dimension of Tablet

The overall dimension is important to measure before selecting the machine of your choice. For that, you can simply examine the following six indices of tablets such as:

- Length,

- Length And Width,

- Length + Width + Depth,

- Length × Width,

- Length × Width × Depth

- Weight

VI.What is your required production capacity? How many per minute per hour?

Tablet press machine speed represents how many tablets/minute/hour it produces. Knowing the production capacity helps the vendor to offer you the best fit option for your production requirement.

If you have a goal for a particular quantity of tablets per hour, day, week, or year, just run the math to estimate the equivalent tablet per minute.

Generally, if your production requirements are intermittent or only a handful per minute, you would likely be better served with a semi-automatic tablet press or manual tablet press machine.

While automatic tablet press would be excellent for both speed and efficiency.

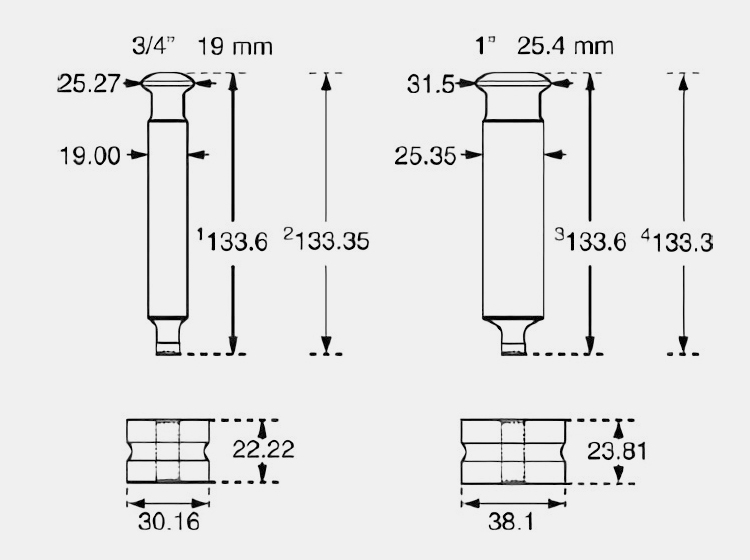

Mentioned below are some useful examples of tablet press machines with tablet output per hour followed by maximum thickness, punch length, and diameter.

| Model | Tablet Output/hour | Max. Tablet Thickness (mm) | Upper & Lower Punch Length (mm) | Upper and Lower punch diameter (mm) |

| GZPS-45 | 405000 | 8 | 133.6 | 25.35 |

| GZPS-55 | 495000 | 8 | 133.6 | 19 |

| GZPS-75 | 675000 | 8 | 133.6 | 19 |

VII.What is your required voltage?

Like the power system of a machine, voltage has to be kept in mind to run your work properly. If the voltage is too high it could damage your machine; similarly, if the voltage is too low, your equipment can operate low or poor.

Therefore, an electrical voltage requirement is crucial that must be assessed when buying a tablet press. Nowadays, manufacturers do ask about voltage requirements to customize or adjust as per the buyer’s domestic power voltage requirement. There are different voltage requirements of different tablet press machines such as 110V, 220V, 380V, and 415V.

Ⅷ.What machine type you are looking for? Single station or multi-station?

Output productivity is dependent upon the type of tablet press. Some presses have more performance efficiency than others. Knowing about its various types facilitates the selection process. Opt for that tablet press, which is compatible with your production needs, e.g:

Single Station Presses

It is also called a single punch or eccentric press. This equipment is the simplest kind of tablet press having a set of die and punches. This machine is small in size and appropriate for installation in little space. The compression force is applied by the upper punch only in a single station press while the lower punch remains stationary.This machine is mostly used in clinical trials and research and development projects. The output range of a single station press is 60-85 tablets per minute.

Multi-station Presses

It is known as multi punch press. This machine has a complicated design having a pair of die and punches.The equipment is structurally large and requires huge space for installation. Both punches (upper and lower) are in continuous rotary motion exerting compression pressure on granules. Large-scale tablet formulation units usually employ multi-station press. The tablets produced by multi-station press are around 100-15,000 per minute.

Ⅸ.What feeding system do you require? Opened or closed?

It was a previous misconception that every feeder of the tablet press is the same. Over the years, huge advancements have been made in feeding systems. Each tablet press is equipped with a specific type of feeding unique to the fluidity of raw material.

You must consider the type of feeder before buying a tablet press because the speed of the equipment is affected by the irregular flow of material. Two types of feeders are available in the market.

Open Feeder

Most tablet presses have open feeders. Granules from these feeders go slowly in die tooling via gravity. Steady granules flow decreases differences in tablet weight. Open feeders usually have poor flow.

Closed Feeder

In these feeders, granules are poured in feeders in two steps. First, granules move from the hopper to the collection bin. Afterward, granules from the bin travel inside feeders. This ensures continuous particle flow that aids in decreasing variation in tablet weight.

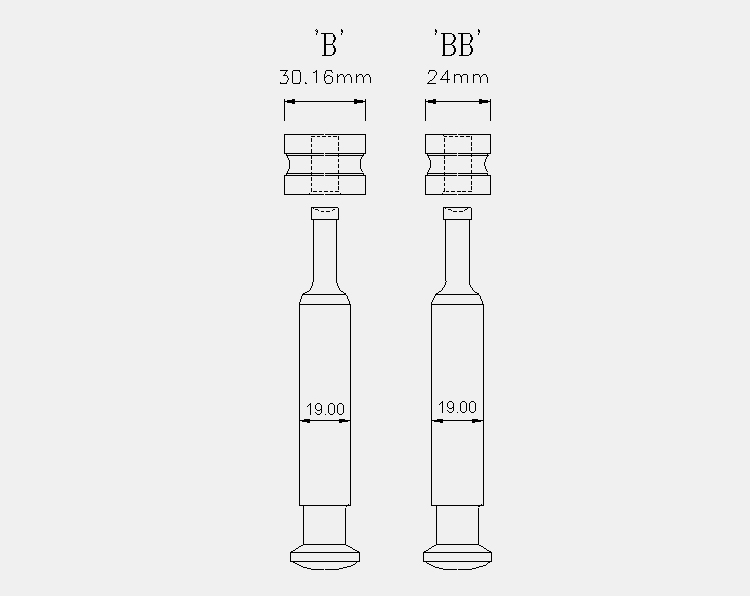

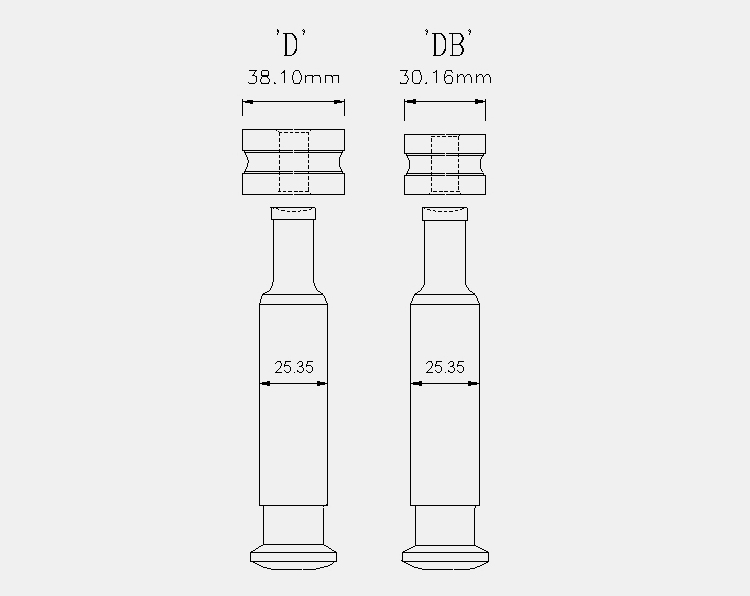

Ⅹ.What tooling size you’re looking for? D- type or B- type?

Tooling is the main component of the tablet press. The size of tooling or punches greatly affects the size of tablets. Before buying, it is very important that you should understand the classification of punches as the thickness of your end products varies with different kinds of punches.

There are two types of punches classified on the basis of outer diameter. These types are:

B Type Tooling

This is also referred to as TSM19, 19 mm being the outer diameter (OD) of B-type tooling.

BB type Tooling

B tooling is further categorized as BB-type tooling. This tooling has the same diameter as of B type but the lower punch in the BB type has a length of 3 and 9/16 inches.

Characteristics

- Due to the smaller OD of B Type, the diameter of end products compressed by this tooling is less than D tooling.

- B-type tooling is 20% to 25% more productive in comparison with D tooling.

- The compression force of B-type tooling is 6.5 tons.

D Type Tooling

These are also called TSM1 with ‘1’ referring to OD of D type tooling which is 1 inch or 25.4mm.

DB Tooling

DB Tooling is a sub-category of D-type tooling. The diameter of the die differs in D type and DB type tooling.

Characteristics

- The hardness of tablets that are formulated with D type is more than that of tablets compressed with B type. It is because of the larger dual time.

- If dissolution of the tablet is dependent upon hardness then tablets pressed by D-type tooling will have lower dissolution.

- The maximum compression pressure applied by this tooling is around 10 tons

| Tooling Types | Tooling OD (mm) | Die Diameter (mm)/ inch | Max. Tablet Size (mm) |

| B | 19 | 30.15/ 1.187 | 16/19 |

| D | 25.4 | 38.1/1.50 | 25/25 |

| BB | 19 | 24.0 /0.945 | 13/24 |

| DB | 25.4 | 30.15/1.187 | 19/19 |

Conclusion

Starting on purchasing a new tablet press? 10- Questions to Answer Before Requesting a Tablet Press Machine filters all necessary requirements may be asked by your manufacturer to refine the machine you need. Contact us with any queries about tablet press machines & we’ll help you discover what you need.

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget,we'll reply you ASAP within 24 hours