10 Critical Tablet Compression Machine Parts

Tablet compression machine is one of the most important device that can help you with producing and completing the tablets for your business. If you would like to know the tablet compression machine, you need to learn the machine parts first.

AIPAK Tablet Compression Machine

Are you familiar with the parts of tablet compression machine? Do you know the layout position and related functions of the components of the tablet compression machine? Following this 10 critical tablet compression machine parts below, you can get the clear understanding of the machine parts. Let's dig in now!

1.Tablet Compression Machine Hopper

Tablet Compression Machine Hopper-sourced: pharmaeducation

The hopper of tablet compression machine is some part of feeding system. It is mainly responsible for feeding your drug granules, powders and mixtures and mixing them into the tablet press. You can choose manual or automated system provisioning. There is a sensor in the hopper. When the material level is low, the machine will automatically alarm.

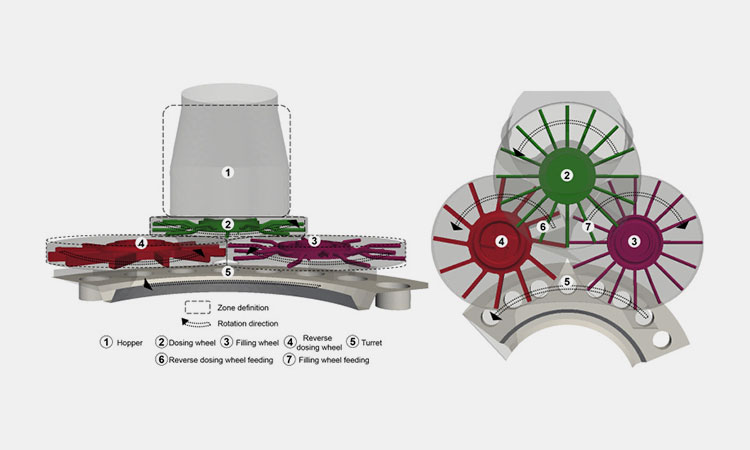

2.Tablet Compression Machine Feeding System

The tablet compression machine feeding system is mainly designed for feeding your drug granules, powders and mixtures from the hopper into the mold cavity, especially during rapid rotation. It consists primarily of an outer shell, any number of rotating internal paddle wheels, and a base.

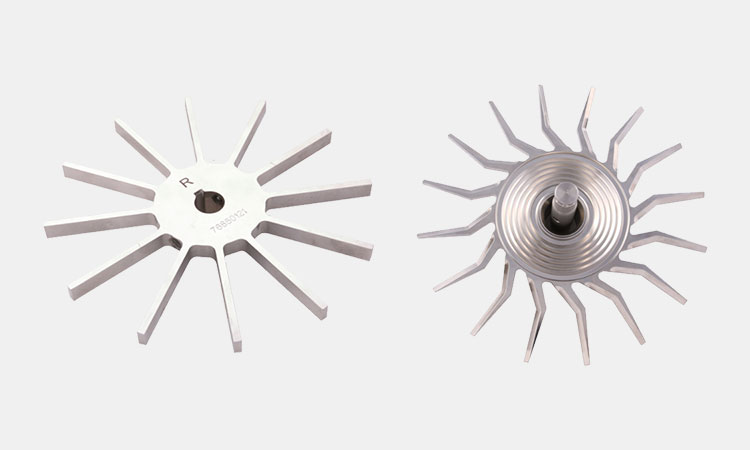

Feeding Paddle

Feeding Paddle-sourced: korsch

The feeding paddle is mainly installed between the feeding system and the turret, and the gap between them is not easy for you to change. It is primarily responsible for good filling of free-flowing, non-viscous blends.

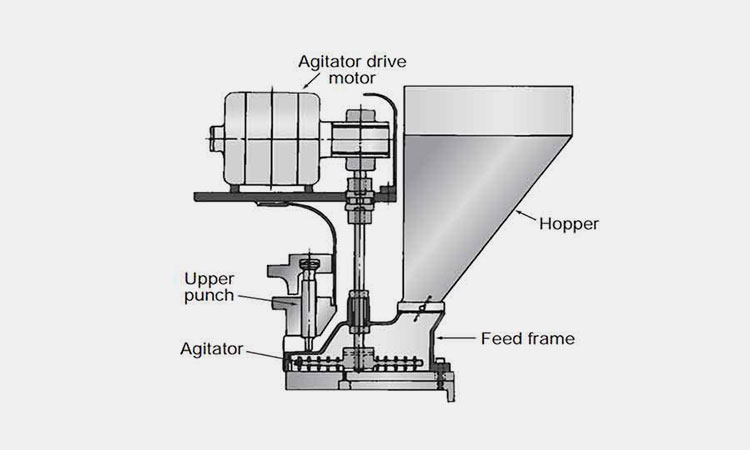

Feeding System

Feeding System-sourced: sdcsalesar

This device is mainly composed of a hopper, a flow regulating valve, a feeding transmission device, a forced feeder, a feeder bracket, a baffle powder return device, etc.

You can adjust the gap between the forced feeder and the turntable working surface according to your needs. The feeding system can ensure adequate filling of powder under any circumstances.

3.Tablet Press Filling Adjustment System

Tablet Press Filling Adjustment System-sourced: sciencedirect

The tablet press filling adjustment system is mainly used to adjust the your weight of subsequent tablets. The filling adjustment is mainly composed of speed-regulating motor, gearbox, displacement ruler, adjustment mechanism, filling track, etc.

Filling Cams

Filling Cams-sourced: natoli

Choosing the correct filling cams is crucial for tablet weighing. If you choose filling cams that are too shallow, the weight of tablet will change. If the selected filling cams are too deep, drug powder will be sprayed onto the mold table.

Dosing Station

The dosing station is able to determine the exact amount of your product fed into the mold cavity before compression, therefore it can determine the tablet weight.

The forward and reverse motion of the speed-regulating motor can move the adjusting mechanism up and down, thereby raising or lowering the filling track screw shaft installed on it, changing the filling amount.

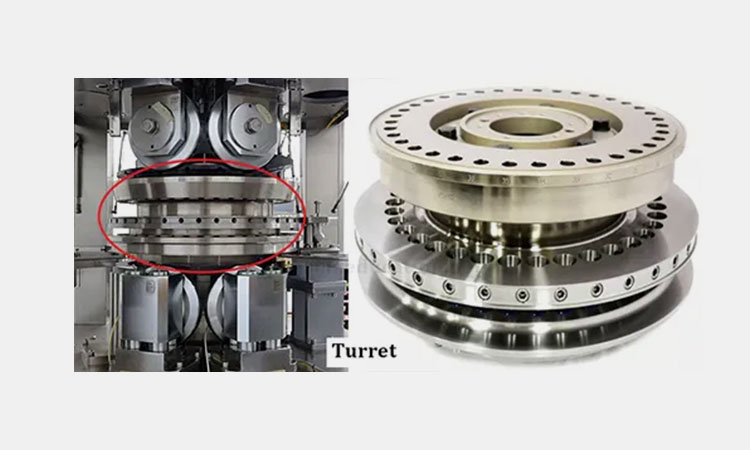

4.Tablet Compression Machine Turret

Tablet Compression Machine Turret-sourced: pharmaeducation

The turret is the main component of tablet compression machine. It consists of the main motor, synchronous pulley, synchronous belt, worm gear reducer, main bearing seat, main shaft, turret and other main components.

During the operation of the equipment, the turret and the main shaft are connected through screws and pins to transmit torque.

Tablet Press Die

Tablet Press Die-sourced: etsy

The die and die cavity determine the shape of your tablets. When drug granules, powders and mixtures are fed into the die holes or cavities, they are compressed into the tablet size, diameter, size and shape you require.

Tablet Press Punches

Tablet Press Punches-sourced: irm

The tablet press punches are mainly composed of two punches (upper and lower). When your drug granules, powders and mixtures are fed into the die hole or cavity, the lower punch will move upward and the upper punch will move downward. Through such movement, the powder in the mold cavity will be compressed into tablets.

Tablet Press Upper and Lower Guide Rail

Tablet Press Upper and Lower Guide Rail-sourced: salepubsm

The tablet press upper and lower guide rail is mainly composed of cylindrical cam and plane cam. The upper guide rail is composed of top-level parallel guide rails, top-level lubricating guide rails, top-level parallel guide rails, top-level upper guide rails, etc., which are respectively fastened to the upper guide rail guide plate.

The lower guide rail is composed of a lower impact lower rail, a lower impact loading and unloading rail, a filling rail, a preload transition rail, a main pressure transition rail, a lower impact top derailment, and a lower impact top derailment.

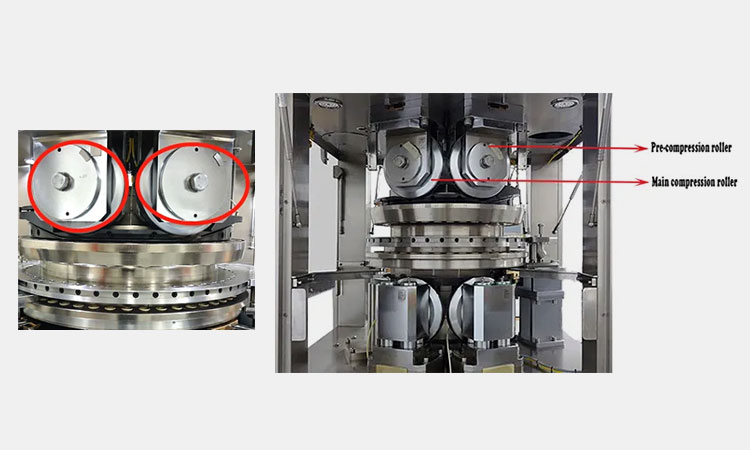

Pre-press Wheel and Main Press Wheel Structure

Pre-press Wheel and Main Press Wheel Structure-sourced: osdmachinery

It consists of an upper pre-pressure wheel assembly, a lower pre-pressure wheel assembly, an upper main pressure wheel assembly, and a lower main pressure wheel assembly. The wheel structure is mainly used to adjust the thickness of your tablets formed after compression.

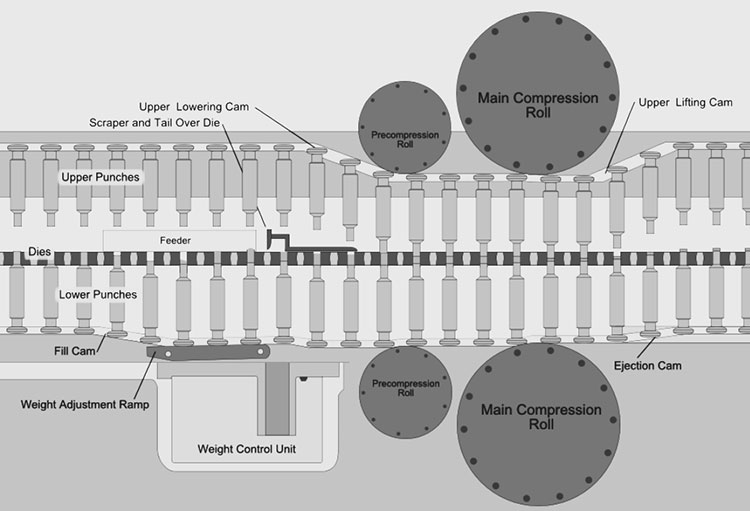

5.Tablet Press Cam Tracks

Tablet Press Cam Tracks-sourced: phxequip

The tablet press cam tracks guide the movement of the upper and lower punches during your tableting process. During the tableting process of the cam track, it can ensure the smooth progress of the tableting process. The cam track helps move the punch up and down as the turret rotates.

6.Tablet Compression Part

Tablet Compression Part-sourced: pharmaeducation

The tablet compression parts mainly consist of pre-compression rollers and main compression rollers.

Pre-compression Rollers

The pre-compression rollers are used to provide you the initial compression force for tableting. Its purpose is to eliminate air that may be present in molds, drug granules, powders and mixtures.

Compression Roller

The main compression roller can provide you with a predetermined and sufficient force to compress the granules into tablets with the required hardness.

Throughout the entire process, the roller remains stable and vibration-free, ensuring consistent tablet thickness and size. Therefore, most tablet compression machines have two sets of pressure rollers.

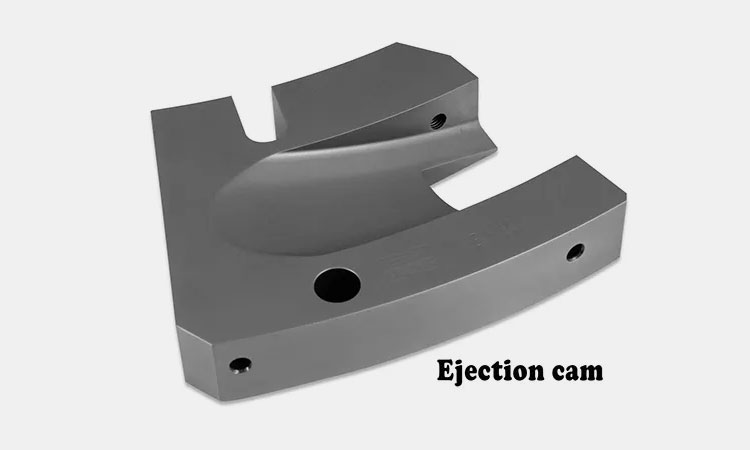

7.Ejection System

The ejection system can remove the compressed finished tablets from the equipment and transfer them to subsequent packaging processes.

Ejection Cam

Ejection Cam-sourced: pharmaeducation

The ejection cam can guide the lower punch to move upward, thereby helping the your tablets to be ejected from the die hole or cavity after compression. After the tablets are compressed and formed, they will be ejected slowly and gradually under the action of the ejection cam.

Take Off Blade

Take Off Blade-sourced: natoli

The take off blade can help push the compressed and ejected tablets to the discharge chute. Once the tablet is pushed out of the mold, it is guided out of the machine by the take off blade and into the tablet ejection chute.

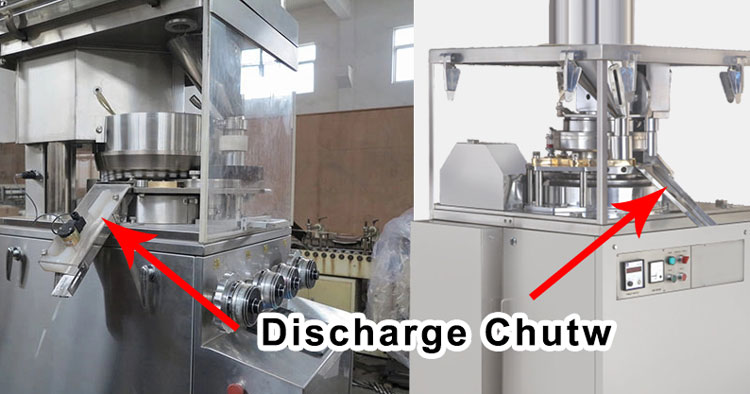

8.Discharge Chute

Discharge Chute-sourced: pharmaeducation

The discharge chute is mainly used to guide tablets into a collection bucket or collection box. After the tablets leave the mold cavity, the discharge chute will guide the tablets to the collection box in sequence to complete the tablet making process. The finished tablets will also undergo quality inspection in batches.

9.Control System

Control System-sourced: natoli

The control system of tablet compression machine is able to control and coordinate most of the machine's functions. The main controls include turret speed, feed speed, temperature, upper and lower punches, product recipe storage and retrieval, electronic audit trail, press force control, on-line tablet sampling, central system interface, etc.

10.Others

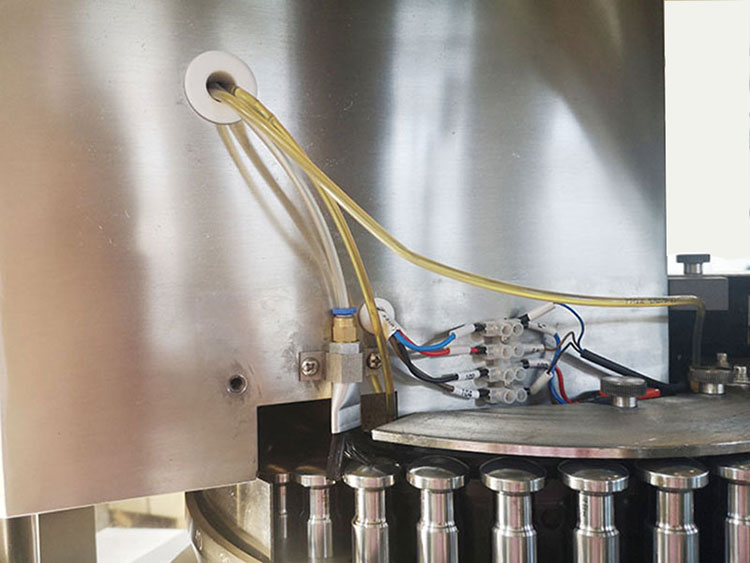

In addition to these components, the tablet compression machine also has other components such as lubrication systems, motors, electrical and hydraulic systems.

Lubrication System

Lubrication System-sourced: pharmacy-machines

The lubrication system of the tablet press mainly consists of oil pumps, hydraulic cylinders, valves, etc. It is mainly used to provide you the necessary lubrication and protection for various parts of the tablet press. A reasonable lubrication system can ensure the stability and normal operation of the entire tablet press.

Hydraulic System

The hydraulic system of the tablet press is a system that uses liquid to transmit pressure and power. During the working process of the tablet press, the motor drives the pump to inject hydraulic oil into the hydraulic system.

The hydraulic oil is controlled by various hydraulic valves and transported to the hydraulic cylinder through the hydraulic pipeline to generate pressure.

Conclusion

After learning these 10 critical tablet compression machine parts, you would have a better understanding of the tablet compression machine and their working principles. There are more detailed and sophisticated parts that we did not cover, if you want to know more about the tablet compression machine and their parts, do not wait to contact us!

Don't forget to share this post!

Tablet Press Machine Related Posts

Tablet Press Machine Related Products

Tablet Press Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for AIPAK’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours