10 Best Pharma Packaging Machines Plus 10 Upgradation Ideas

Recent advancement in engineering and medicines has led to new paths for development and manufacturing of equipment and novel processes for formulation of new drugs. Ongoing development and strict regulatory requirements have increased demands of innovative pharmaceutical machineries. One such type of equipment that has taken full advantage of this evolution is none other than pharmaceutical packaging.

From manual instruments to high tech fully automatic equipment, pharma packaging machines are not only used in pharmaceuticals but also in other food, confectionary, cosmetic and other related industries. A number of equipment can be included under the umbrella of pharma packaging machines, these include packaging machines that process and pack all existing solid and liquid dosage forms.

As a new business prospect in this blog “10 Best Pharma packaging machines Plus 10 Upgradation Ideas” we have discussed a must have packaging machines and their features. Without further ado let’s Go!

1.Capsule filling machine

Capsules filling machines are used for filling various ingredients in capsules including but not limited to pellets, powders, liquids, mini-tablets, inhalation powders and their combinations.

These automations are used for filling capsules of sizes 000, 00, 1, 2, 3, 4, and 5. Some of these machines can fill safety sized capsules with size ranging from A-E.

They are designed to handle large batches and are able to process dosing volume of 0.1-1.2 ml with accuracy and fills capsules with minimal wastage of powders.

Advantages

- Can fill and seal maximum of 450000 capsules per hour.

- Assure uniformity of drug ingredients

- Reduced power consumption

- Recycle surplus powder

2.Hard capsule liquid filling

In pharmaceutical industry, hard capsule liquid filling machine has a profound value since these machines are employed for filling of lipophilic and low dose ingredients in two-piece hard gel capsules.

Hard capsules liquid fillers are versatile and can speedily fill paste, suspension, emulsion etc. in hard gel capsules.

Vacuum system in these automations is employed for capsule separation while the function of ceramic pumps is to dose capsules. Clumped hollow capsules are detected by highly sensitive fiber optics system.

Advantages

- Manufacturer colorful liquid capsules and seals them with matching bands

- Ensure liquid capsules fulfill international quality standard

- Lower noise rate

- Minimal filling error rate

3.Soft gel encapsulation machine

These equipment are typically used for manufacturing softgel capsules. These encapsulate unpleasant and bitter tasting compounds into a single piece.

High tech sensors reduce material wastage and lubrication units are employed in these machines for decreasing the use of white oil. V-type polytetrafluoroethylene injection pumps are used for accurate hermetic sealing while function of extraction devices is to prevent drug dust contamination.

These machines can also be employed for manufacturing paint balls; small size balls filled with paints used in highly popular paint ball game.

Advantages

- Produce easy to shallow softgel capsules

- Inhibits the entrance of debris in capsules by hermetically sealing them

- High production rate of about 500,000 to 900,000 softgel capsules per 60 minutes.

- Fill milligrams to hundred grams of drug ingredients.

4.Tablet counting line

In solid dose manufacturing line, tablet counters are of significant importance since they are employed for counting various solid doses such as standard pills, mini-tablets, caplets, hargel capsules and softgel capsules with high accuracy and precision.

They employ optic and infra-red sensors for counting about 2000-4000 doses per minute. Servo drives are employed for material loading and vacuum rejection system for removing faulty tablets.

Tablet counting lines are manufactured keeping in mind guidelines of cGMP, FDA, and ISO.

Advantages

- Have accuracy and precision in solid dose count with error rate of less than 1%.

- Indirect contact with tablets cuts down product damage.

- Remove broken or chipped tablet.

- Cost effective counting.

- Can be attached to other manufacturing equipment to form a complete production line.

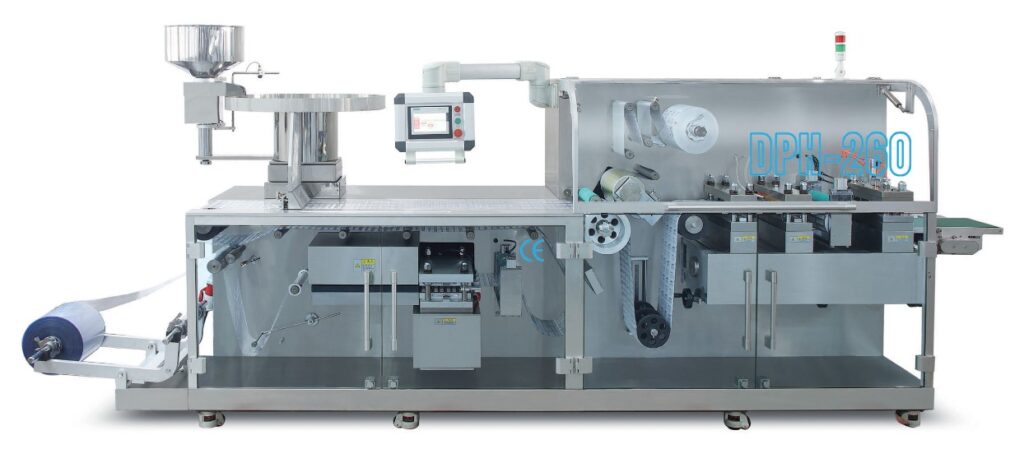

5.Blister packing machine

These automations have a central place in packaging especially pharmaceuticals but can be employed by other manufactures. These produce blister solution for tablets, capsules, vials, injections, ampoules, etc.

In this machinery, high capacity feeders and drug dust removal systems are utilized for packing pharma product. Cross-punching systems are employed for blister trimming and lowering film waste. Servo motors aid in precise and uniform film unwinding and blister molding.

Advantages

- Higher packaging rate and fabrication of 600 blisters per minute.

- Use less polymer material per blister thus has minimal material waste.

- Produce aesthetically pleasing packaging containers

- Low running expenses

- Blister packaging machines have vision systems and cameras for identifying flawed blister packs.

6.Strip packing machine

They are the key machines in primary packaging of tablets and capsules. They hermetically seal solid dosages forms between poly aluminum, plastic or paper layers.

These are equipped with vibratory hopper feeder and sensors to eliminate powder debris from pills. With PLC programming various functions for instance tablet counting, embossing, printing, and cutting are controlled.

Electronic detector assists in controlling the strip length and number of pills per strip. Also equipped with optic fibers that are used for identifying defective strips.

Advantages

- Offer child-proof pharma packaging.

- Supplies premium mechanical protection against moisture and oxidative conditions

- Assists in keeping dose accuracy of tablets and capsules

- Manufactures tamper-proof packaging

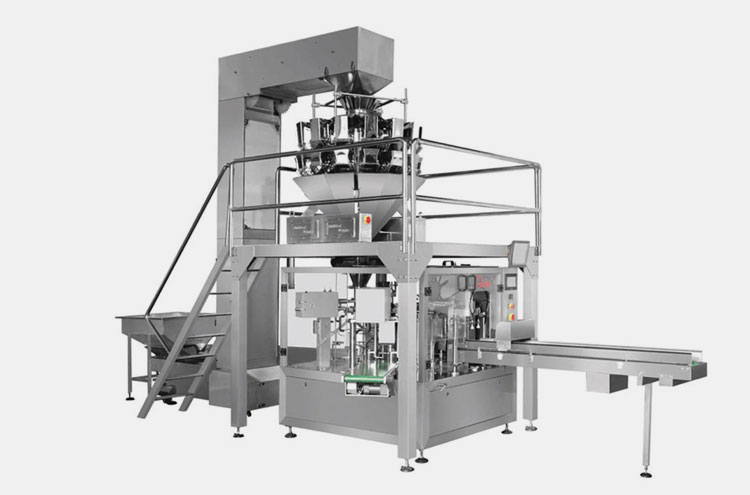

7.Doypack packing machine

Pharmaceutical paste, herbal oils, cannabis products, and ointment powders virtually anything can be packed inside stand up pouches by Doypack packing machines. These packers are versatile and can expediently fill flat pouches, zipper pouches, guesset bag etc.

Although every unit has different mechanical characteristics, most of these machines are equipped with magnetic servo motors that act as driving unit. Temperature control regulates the sealing of pouches while detection systems and alarms are present for spotting abortive opened pouch and faults in equipment.

Advantages

- Manufacture aesthetically appealing and stable pouches

- Provide high protection barrier against severe condition and microbial contamination.

- Offers most economical packaging

- Product freshness is maintained due to air removal before sealing.

- Stand up pouches have added advantage

8.Sachet filling and packing machine

These equipment are of pivotal significance in packaging of various pharmaceutical and nutraceutical powders. They readily fill and pack free-flowing granular antibiotics, gastric supplement and powders in three-sided four-sided, rounded, pour spout pouches

Sachet filling and packing machines have multiple lanes from 2 up to 10 lanes. Servo driven rolls in these equipment controls foil unwinding. These can package maximum of 600 sachets per minute without producing vibrations.

These equipment have auger fillers and microsphere dosing systems for non-free and free flowing powders respectively.

Advantages

- Autonomously cut, fold, fill, seal, and trim sachet.

- Reduce significant expenses on materials.

- Filling volume and size of powders is ensured with ±0.5% accuracy

- Packs various aerated and fine particle powders in airtight sachets

9.Flow-wrap machine

These machines are ideal for packaging soft and irregular shaped products such as wet wipes, gauze, masks, IV bags, injections, and enema.

They effortlessly seal film from four sides while maintaining good film tension and have various options for sealing for instance hot sealing, cold sealing, straight or curved sealing.

Product reactivity is maintained by their temperature control. These machines have optimum packaging rate of 800 packs per minute.

Advantage

- Safely and hygienically packs pharma consumables

- Seal products in air tight packaging and provide UV light protection

- Nitrogen use maintains product freshness

- Ensure highest package quality of products

10.Cartoning machine

Secondary or tertiary packaging revolves around cartoning machines. These equipment are backbone of sturdy packaging since these machines not only package products in folded, collapsible and slotted cartons but also ensure their safety and security.

These innovations have built-in overload protection and use lower energy resources. Some models of cartoning machines have compact balcony style construction and are provided with robotic systems for product loading. They gently handle fragile items and are easily cleaned within short period.

Advantages

- Bulk quantities of pharma products are packaged inside cartons

- Versatility in terms of packaging various products concurrently.

- Scale up packaging efficiency.

- Provide high level of protection to fragile pharma goods such as vials and ampoules

Now let us ponder certain features that will enhance your machine’s performance and working capacity.

11.Customization

Leading supplier can assist in customizing your pharmaceutical machines by replacing the machine parts with the component of your choice. In addition, optional accessories such as capsule polisher, deblistering devices, printing units, fume extraction systems, feeders etc. are integrated with existing component for giving your machine a new look.

These upgrades will help to reconfigure pharmaceutical packaging equipment according to modern standards and will also increase your production capacity.

12.Compliance

Compliance is an important aspect that should be taken into consideration when upgrading your pharma packaging equipment.

You can apply for FDA, cGMP, ISO, etc certification by adhering to rules imposed by governing bodies and by following clean practices in your pharma line.

This will ensure that pharma products packaged in your plant is safe for patient use and also increases the trust of customer for quality of your products.

13.Automation

Increasing automation of packaging machine can give a leg to your packaging capability while lowering the burden on your workforce.

Automation of these equipment can be improved by installing machine parts that work by themselves without the need of operator supervision and by investing in robotic controls.

This upgradation increases efficiency of packaging process and minimizes packaging errors.

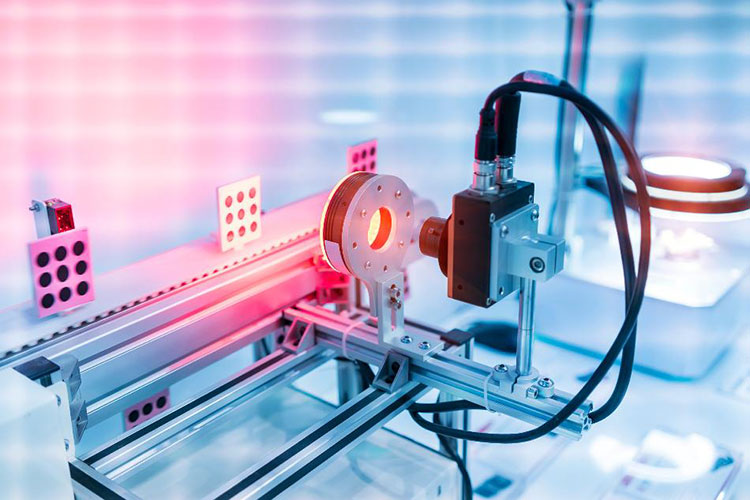

14.Advanced electronics

Sophisticated computerized systems and electronics is failsafe way of upgrading your packaging line. You can furnish your machines with HMI touch screens, alarms, sensors, indicator lights, camera, fiber optics and vision systems for detecting error at any stage of your packaging operation.

These advanced electronics assist in self-diagnosis, detect and remove defective products from the system.

15.Accuracy and precision

You can achieve greater level of precision and accuracy on your pharmaceutical packaging instruments by minimizing the number of operators in your plant. This reduces the risk of human error and product wastage.

Moreover, extreme standards of accuracy in measurement and product handling is gained by switching old electronics with top-notch technology for instance replacing traditional weight measurement systems with optic sensors.

16.Data collection

Information technology has evolved over the past years. Upgradation to latest hardware, software, and operating systems can enhance your data collection and traceability.

Recording data like employee information, production output, time, system pressure and temperature, energy and water use is essential in maintaining efficiency of packaging operation. This data collection facilitates in formulating informed decision. Most advanced machines are equipped with built-in data and management system but you can also upgrade your old models by installing new and upgraded software and data integrated systems.

17.Flexibility

Enhancing flexibility means changing in product and container handling configuration, package profile and increasing packaging rate. This increases aesthetic looks for finished product and foster customer positive reception for your packaged good.

Ability to pack various pharmaceutical products can be altered by simple re-programming of equipment interface. This reprogramming is done for storing and executing multiple data recipes.

Furthermore, you can increase flexibility by implementing robotic automations in your plant, modifying end effectors or by installation new control software on your systems.

18.Fast changeover and cleaning

Quick changeover and cleaning procedures can minimize labor work burden, lower downtime and prevent risk of contamination. This speeds up packaging time and foster packaging quality.

The changeover rate and cleaning time in pharmaceutical packaging systems can be reduced by investing in lightweight and tool less dismantled parts. Moreover, quick release lever, programmable interfaces, ventilation systems, compressed air units and sensors cut down part change and cleaning time.

19.Low maintenance and labor cost

Maintenance and labor cost is crucial aspect that should be kept in mind when planning upgradation of pharma packaging machine.

Furbishing your pharmaceutical packaging system with lubrication-free devices and monitoring control systems decrease the need of equipment maintenance.

Scheduling maintenance task ahead can reduce surprise component failure. Spending money on self-maintaining parts and robotic technology can not only cut down your maintenance time but also lowers need for maintenance staff. This in turn lessens labor wages and running cost.

20.Integration

Pharma packaging efficiency can be optimized by integrating various packaging machine together. You can upgrade your production line by installing combination of machines such as capsule filling, blistering packaging and cartoning machine.

This will lower your packaging time and expenses. Packaging integrator will aid you in planning and designing your packaging line and will also help you in selecting compatible machines.

Conclusion

Various equipment fall under the category of pharmaceutical packaging machines. These have wide ranging applications and benefits for your productions. Upgradation of these automations require altering various aspects of machines like customization of machinery, installing advanced technology, increasing automation capabilities, and lowering changeover, cleaning and maintenance time. If you have additional inquires related to pharma packaging machine you can contact our 24/7 customer service.

Don't forget to share this post!

Blister Packaging Machine Related Posts

Blister Packaging Machine Related Products

Blister Packaging Machine Related Videos

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 6426 8586

Want the best price & newest pharmaceutical machinery buying guide,tips and trends sent straightly to your box?Sign up for Aipak’s monthly newsletter,we’re free for your consultation and Offer you the most suitable solutions!

The Buyer's Guide

- Capsule Filling Buyer's Guide

- Blister Packaging Buyer's Guide

- Tablet Counting Buyer's Guide

- Tube Filling Buyer's Guide

- Cartoning Buyer's Guide

- Gummy Making Buyer's Guide

- CO2 Extraction Buyer's Guide

- Empty Capsules Buyer's Guide

- Suppository Filling Buyer's Guide

- Tablet Coating Buyer's Guide

- Tablet Press Buyer's Guide

- Softgel Encapsulation Buyer's Guide

Most Popular

- 7 Importance Of Pharmaceutical Packaging In Different Applications You Must Know

- 6 Advantages You Must Know About Tablet Counting Machine

- 8 Advantages of Blister Packaging You Must Know

- 6 Critical Applications of Automatic Capsule Filling Machine

- 6 Stations You must Know to Improve the Filling Quality of Automatic Capsule Filling Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours